Magnetic rare earth barium ferrite nano purifying catalyst, as well as preparation method and application thereof

A technology for purifying catalyst and barium ferrite, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as scarcity of precious metal resources, and achieve the effects of low price, fast gelation, and reduction of raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

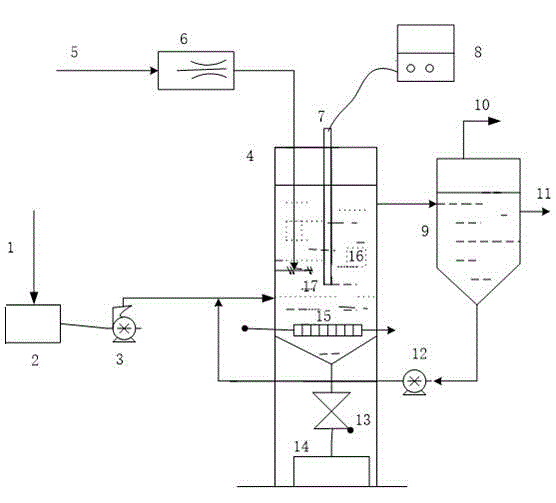

Method used

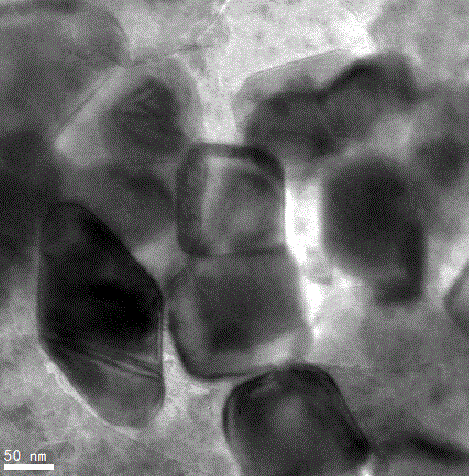

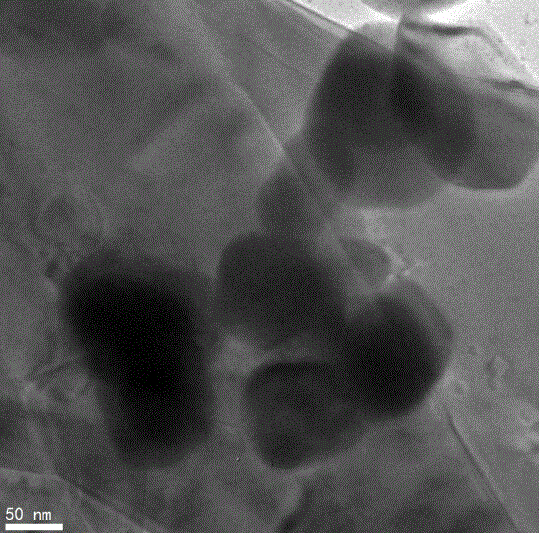

Image

Examples

Embodiment 1

[0068] Embodiment 1: The preparation method of magnetic rare earth barium ferrite nano purification catalyst is as follows:

[0069] 1. Selected chemical substances and materials

[0070] The chemical substances and materials required for the preparation should be selected and controlled for quality and purity:

[0071]

[0072] 2. Clean the roaster

[0073] The roasting furnace for preparation and use should be cleaned, and the dust and harmful gas substances in the furnace should be removed with compressed air to make the furnace clean;

[0074] 3. Drying treatment

[0075] Weigh 200g±5g of neodymium oxide, place it in a quartz boat, and dry it in a vacuum drying oven at a drying temperature of 120°C±2°C, a vacuum degree of -18Pa, and a drying time of 30min;

[0076] 4. Prepare the solution

[0077] (1) Take by weighing 1 ± 0.001mol ferric nitrate nonahydrate and prepare 0.5 ± 0.001mol / L ferric nitrate solution in a 2000 milliliter volumetric flask with deionized wate...

Embodiment 2

[0106] What is different from Example 1 is that Fe in the ratio of raw material composition 3+ 、Ba 2+ 、Nd 3+ , (C 6 h 5 o 7 ) 3- The molar ratio is 9:0.8:0.2:20, the firing temperature of the firing process is 750°C, and the other processes are the same as in Example 1.

[0107] 1. Selected chemical substances and materials

[0108] The chemical substances and materials required for the preparation should be selected and controlled for quality and purity:

[0109]

[0110] 2. Clean the roaster

[0111] The roasting furnace for preparation and use should be cleaned, and the dust and harmful gas substances in the furnace should be removed with compressed air to make the furnace clean;

[0112] 3. Drying treatment

[0113] Weigh 200g±5g of neodymium oxide and place it in a quartz boat, and place the quartz boat in a vacuum drying oven to dry at a drying temperature of 120°C±2°C, a vacuum degree of -18Pa, and a drying time of 30min;

[0114] 4. Prepare the solution

...

Embodiment 3

[0146] The difference between this embodiment and embodiment 1 is that Fe in the raw material composition ratio 3+ 、Ba 2+ 、Nd3+ , (C 6 h 5 o 7 ) 3- The molar ratio of 2:0.9:0.1:6, using pickled elm rubber powder to carry out sol treatment, other processes are the same as in Example 1.

[0147] 1. Selected chemical substances and materials

[0148] The chemical substances required for preparation should be selected and quality purity controlled:

[0149]

[0150] 2. Clean the roaster

[0151] The roasting furnace for preparation and use should be cleaned, and the dust and harmful gas substances in the furnace should be removed with compressed air to make the furnace clean;

[0152] 3. Drying treatment

[0153] Weigh 200g±5g of neodymium oxide, place them in quartz boats, and dry them in a vacuum oven at a drying temperature of 120°C±2°C, a vacuum degree of -18Pa, and a drying time of 30min;

[0154] 4. Preparation of pickling elm rubber powder

[0155] ①Choose five...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com