Preparation method for graphene like cobaltosic oxide nano film material and application of electrode slice

A technology of cobalt tetroxide nanometer and graphene, applied in cobalt oxide/cobalt hydroxide, nanotechnology, nanotechnology and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Cobalt acetate and sodium acetate were mixed with deionized water to prepare 250g / L cobalt acetate solution and 180g / L sodium acetate solution. Take one liter of each of the two solutions and put them in a constant temperature water bath at 45°C for 5 minutes, then pour 200 mL of 28% ammonia solution per liter of solution into the above mixed solution, stir evenly, and obtain a sodium salt Cobalt-ammonia complex solution, and then pour 120 mL of hydrogen peroxide per liter of solution into the mixed solution, and transfer the solution to a hydrothermal device for treatment. The temperature is set to 120°C and the duration is 16 hours. After the reaction is completed, the obtained black precipitate is washed and centrifuged three times with deionized water and absolute ethanol, and dried in an air drying oven for 10 hours to obtain the cobalt tetroxide product.

[0030] The product is uniformly mixed with acetylene black and PTFE binder in a mass ratio of 75:10:15, and the ...

Embodiment 2

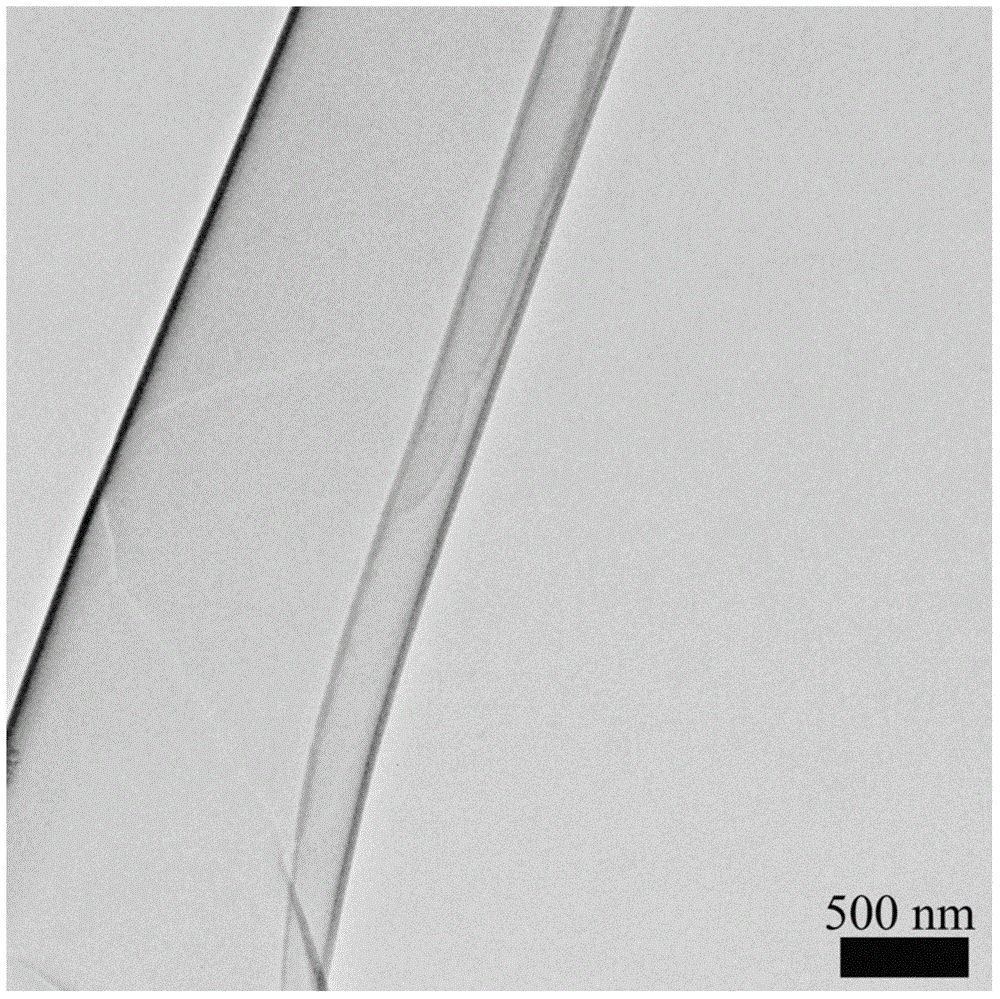

[0032] Cobalt nitrate and sodium nitrate were mixed with deionized water to form a 320g / L cobalt nitrate solution and a 240g / L sodium nitrate solution. Take one liter of each of the two solutions and put them in a constant temperature water bath at 65°C for 8 minutes at the same time, then pour 300mL of 28% ammonia solution per liter of solution into the above mixed solution, stir evenly, and obtain a sodium salt Cobalt-ammonia complex solution, and then 180mL of hydrogen peroxide per liter of solution is poured into the mixed solution, the solution is transferred to a hydrothermal device for treatment, the temperature is set to 150°C, and the duration is 12 hours. After the reaction is completed, the obtained black precipitate was washed and centrifuged three times with deionized water and absolute ethanol, and dried in an air drying oven for 8 hours to obtain a graphene-like cobalt tetraoxide nano-film with a size area of about 30μm×30μm and a thickness of about It is 2.9nm...

Embodiment 3

[0035] Cobalt acetate and sodium acetate were mixed with deionized water to prepare a 400g / L cobalt nitrate solution and a 300g / L sodium acetate solution. Take one liter of each of the two solutions and put them in a constant temperature water bath at 55°C for 10 minutes, then pour 400mL of 28% ammonia solution per liter of solution into the above mixed solution, stir evenly, and obtain a sodium salt Cobalt-ammonia complex solution, and then pour 250 mL of hydrogen peroxide per liter of solution into the mixed solution, transfer the solution to a hydrothermal device for treatment, and set the temperature to 120°C and the duration of 18 hours. After the reaction is completed, the obtained black precipitate is washed and centrifuged three times with deionized water and absolute ethanol, and dried in an air drying oven for 8 hours to obtain the cobalt tetroxide product.

[0036] The product is uniformly mixed with acetylene black and PTFE binder in a mass ratio of 75:10:15, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com