RT detector suitable for epitaxial material and application thereof

A technology of epitaxial materials and detectors, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems that the reflected signal exceeds the receiving range of the detector, the reflected signal exceeds the receiving range, and affects the accuracy, so as to realize the composition of the epitaxial layer and uniform growth control, avoid reflection signal out of control, and precisely control the effect of growth temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

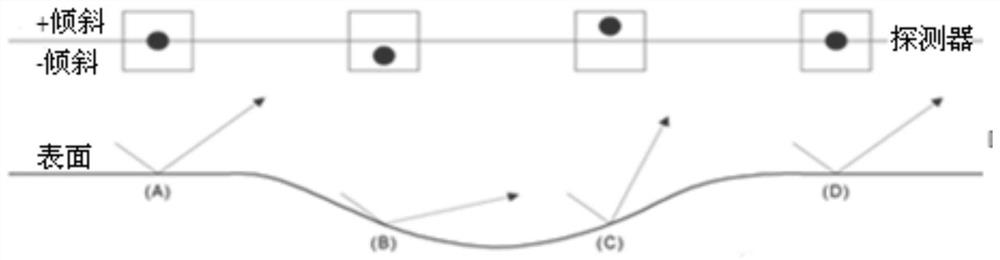

[0046] Embodiment 2 of the present invention is: a method for using an RT detector suitable for epitaxial materials, the method comprising the following steps:

[0047] placing the epitaxial wafer in the epitaxial wafer carrier, and controlling the motion state of the epitaxial wafer to be consistent with the carrier;

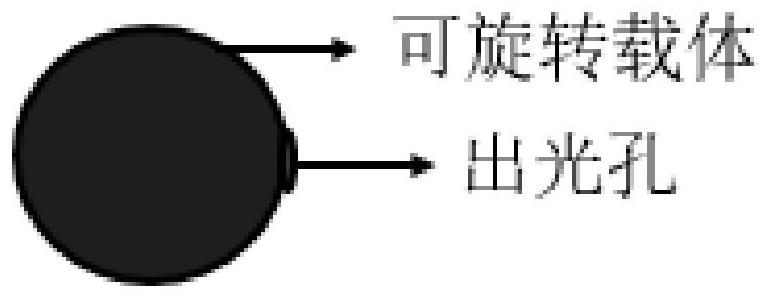

[0048] Adjust the monitoring mode in the RT detector according to the growth state of the epitaxial wafer to observe the growth process of the epitaxial wafer; wherein, the adjustment of the monitoring mode is to calculate the warping degree and Deformation feature, through the stepping motor to adjust the light direction of the eye-shaped light source.

Embodiment 3

[0049] Embodiment three of the present invention is: a method for using an RT detector suitable for epitaxial materials, the method comprising the following steps:

[0050] placing the epitaxial wafer in the epitaxial wafer carrier, and controlling the motion state of the epitaxial wafer to be consistent with the carrier;

[0051]Adjust the monitoring mode in the RT detector according to the growth state of the epitaxial wafer to observe the growth process of the epitaxial wafer; wherein, the adjustment of the monitoring mode is to calculate the degree of warpage and the intensity of the light received by the receiver. Deformation characteristics, change the position of light output by rotation, and record the direction of light output in polar coordinates.

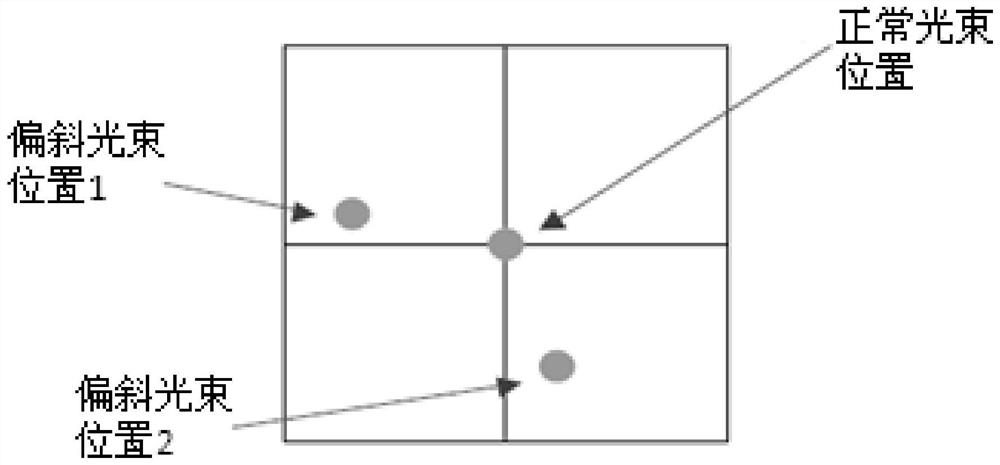

[0052] The method for calculating the degree of warpage of the epitaxial wafers in Examples 2 and 3 of the present invention is as follows:

[0053] The position of the reflected light spot detected by the receiver is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com