g-c3n4-doped polyimide composite material, and preparation and application thereof

A technology of polyimide and composite materials, applied in the field of anti-radiation applications, polyimide composite materials, and preparation, can solve the problems of poor mechanical properties, containing toxic heavy metal ions, unsatisfactory heat resistance, etc. The effect of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: g-C 3 N 4 Preparation of:

[0051] Weigh 3g of cyanamide into the crucible, raise it from the greenhouse to 500, 520, 530, and 550°C in the muffle furnace at a rate of 2.3°C / min for 4 hours, keep the temperature at the set temperature for 4 hours, and then cool down naturally . After cooling to room temperature, take it out, grind the sample into powder, put it into a glass bottle, seal it up for measurement and weigh it.

Embodiment 2

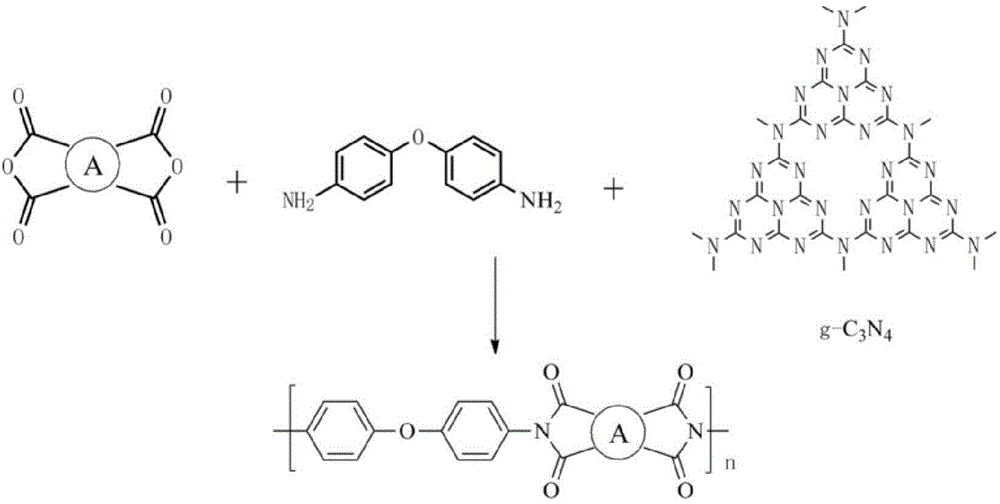

[0052] Example 2: g-C 3 N 4 The preparation of a polyimide composite film with a content of 5% and a size of 5 × 5 × 1 cm is as follows:

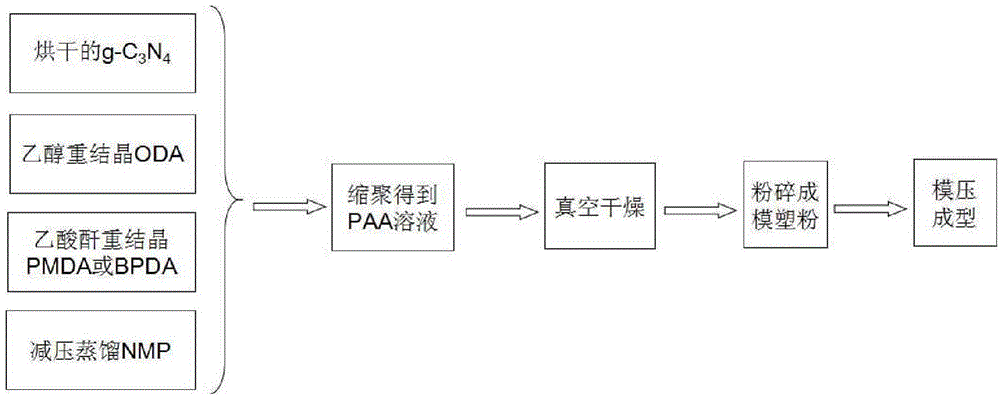

[0053] (1) Recrystallize an appropriate amount of benzoic dianhydride and 4,4'-diamine diphenyl ether with acetic anhydride and ethanol respectively. And a certain amount of polar solvent N-methylpyrrolidone (NMP) was distilled under reduced pressure.

[0054] (2) Add 15.11g (0.1500mol) of diamine to a 250ml three-necked flask equipped with mechanical stirring, and add 150ml of distilled solvent NMP. After mechanical stirring until the diamine is dissolved, add 1.6647g of g-C 3 N 4 After uniform dispersion, slowly add 16.52 g (0.1530 mol) of dianhydride in batches. The reaction was stirred at room temperature for 5 hours to obtain a viscous polyamic acid solution PAA.

[0055] (3) After the reaction is complete and the viscosity rises, pour the PAA solution into a glass plate with a size of 5×5×1 cm, put it into a vacuum drying oven f...

Embodiment 3

[0056] Example 3: g-C 3 N 4 The preparation of a polyimide composite film with a content of 10% and a size of 5 × 5 × 1 cm is as follows:

[0057] (1) Recrystallize an appropriate amount of benzoic dianhydride and 4,4'-diamine diphenyl ether with acetic anhydride and ethanol respectively. And a certain amount of polar solvent N-methylpyrrolidone (NMP) was distilled under reduced pressure.

[0058] (2) Add 15.11g (0.1500mol) of diamine to a 250ml three-necked flask equipped with mechanical stirring, and add 150ml of distilled solvent NMP. After mechanical stirring until the diamine is dissolved, add 3.3295g of g-C 3 N 4 After uniform dispersion, slowly add 16.52 g (0.1530 mol) of dianhydride in batches. The reaction was stirred at room temperature for 5 hours to obtain a viscous polyamic acid solution PAA.

[0059] (3) After the reaction is complete and the viscosity rises, pour the PAA solution into a glass plate with a size of 5×5×1 cm, put it into a vacuum drying oven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com