Fluorescent compound using pyrochlore structure metatitanic acid lanthanum as substrate and preparation method and application

A fluorescent compound and pyrochlore structure technology, applied in the field of fluorescent compounds, can solve the problems of lack of red emission components, insufficient color rendering index, and insufficient luminous intensity, etc., and achieve the effect of stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

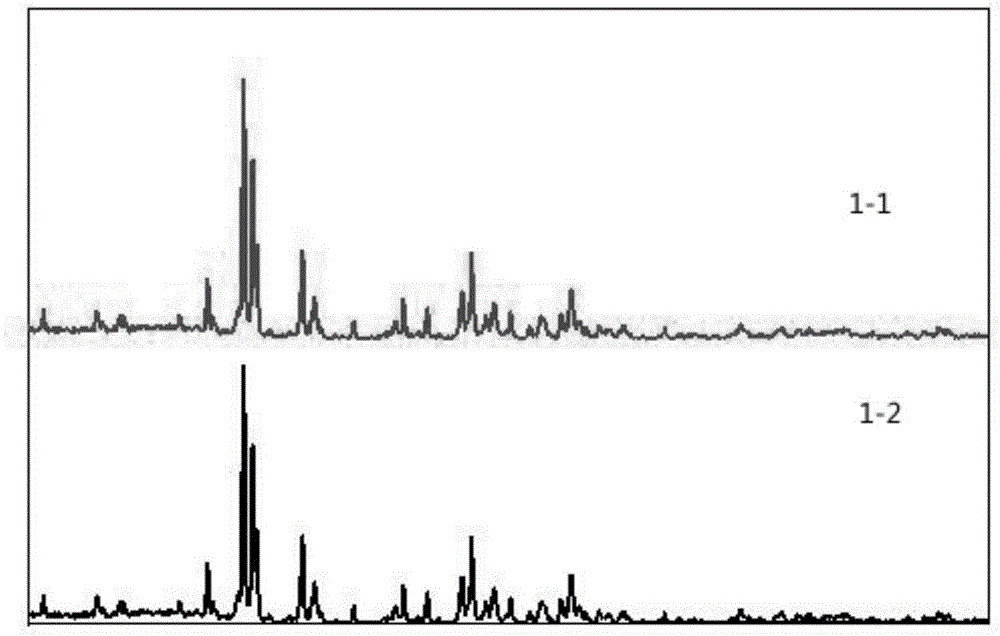

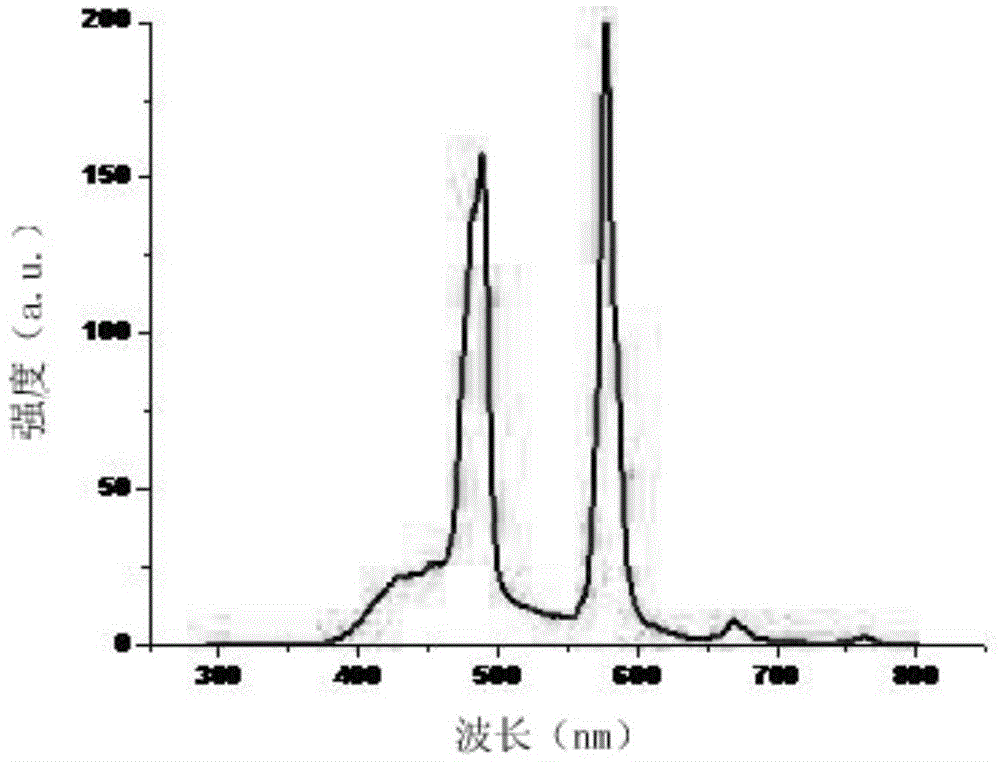

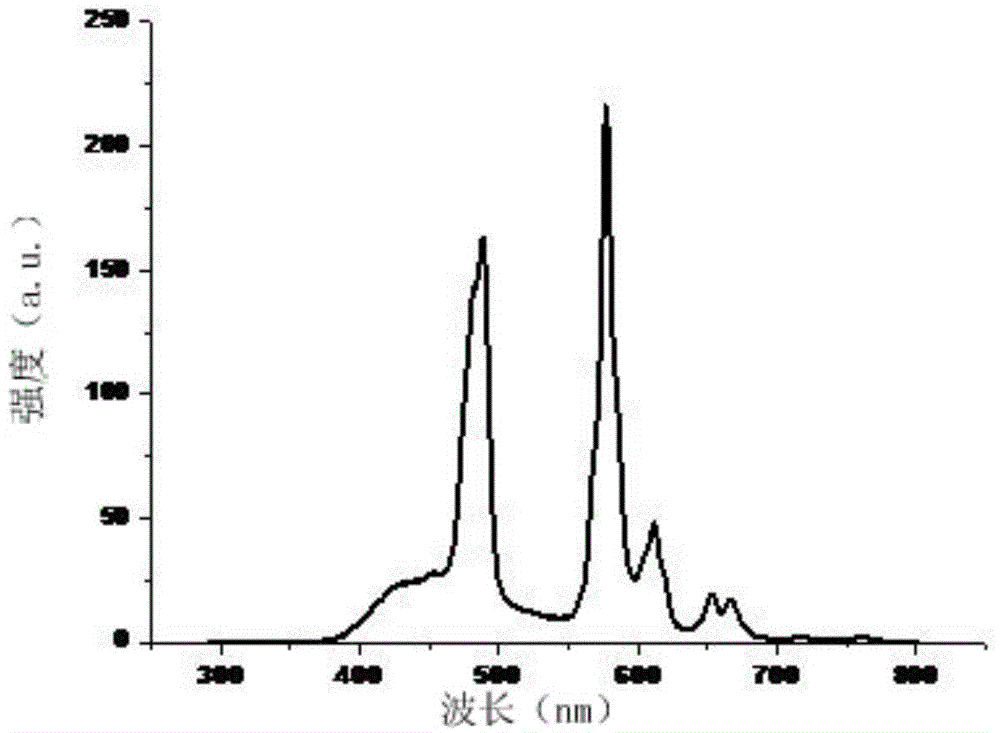

Method used

Image

Examples

Embodiment 1

[0044] Pyrochlore structure lanthanum titanate-based fluorescent compound, the chemical formula is La 1.98 Dy 0.02 TiO 5 , made by the following steps:

[0045] (1) Weigh 1.98 mmol of lanthanum nitrate and 0.02 mmol of dysprosium acetate and dissolve them in deionized water to obtain solution A; weigh 1 mmol of tetrabutyl titanate and dissolve them in 50 mL of methanol to obtain solution B;

[0046] (2) Mix solution A and solution B, add 4 mmol acetic acid dropwise to make the pH<3, stir for 1 hour to obtain a clear solution C, raise the temperature of solution C to 50°C, and keep it in a water bath for 3 hours to obtain a precursor gel;

[0047] (3) Put the precursor gel in a corundum crucible, calcined in a muffle furnace, and calcined in an air atmosphere at a temperature of 1100° C., calcined for 4 hours, kept for 2 hours, and cooled to room temperature with the furnace to obtain a calcined product;

[0048] (4) The calcined product is pulverized, ground, passed through...

Embodiment 2

[0051] Pyrochlore structure lanthanum titanate-based fluorescent compound, the chemical formula is La 1.972 Dy 0.02 SM 0.008 TiO 5 , made by the following steps:

[0052] (1) Weigh 1.972mmol of lanthanum acetate, 0.02mmol of dysprosium carbonate and 0.008mmol of samarium acetate and dissolve them in deionized water to obtain solution A; weigh 1mmol of tetrabutyl titanate and dissolve them in 60mL of ethanol to obtain solution B;

[0053] (2) Mix solution A and solution B, add 30 mmol of carbonic acid dropwise to make the pH<3, stir for 2 hours to obtain a clear solution C, raise the temperature of solution C to 150°C, and keep it in a water bath for 6 hours to obtain a precursor gel;

[0054] (3) Put the precursor gel in a corundum crucible, calcined in a muffle furnace, and calcined in an air atmosphere at a temperature of 1200° C., calcined for 2 hours, kept for 3 hours, and cooled to room temperature with the furnace to obtain a calcined product;

[0055] (4) The calcin...

Embodiment 3

[0058] Pyrochlore structure lanthanum titanate-based fluorescent compound, the chemical formula is La 1.968 Dy 0.02 SM 0.012 TiO 5 , made by the following steps:

[0059] (1) Weigh 1.968 mmol of lanthanum carbonate, 0.02 mmol of dysprosium nitrate and 0.012 mmol of samarium nitrate and dissolve them in deionized water to obtain solution A; weigh 1 mmol of tetrabutyl titanate and dissolve them in 70 mL of propanol to obtain solution B;

[0060] (2) Mix solution A and solution B, add 25 mmol of nitric acid dropwise to make the pH<3, stir for 1.5 hours to obtain a clear solution C, raise the temperature of solution C to 60°C, keep it in a water bath for 4 hours, and obtain a precursor gel;

[0061] (3) Put the precursor gel in a corundum crucible, calcined in a muffle furnace, and calcined in an air atmosphere at a temperature of 900° C., calcined for 6 hours, kept for 4 hours, and cooled to room temperature with the furnace to obtain a calcined product;

[0062] (4) The calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com