Bi-color antibacterial EVA footwear and preparation method thereof

An antibacterial agent and raw material technology, applied in the field of organic polymer compounds, can solve the problems of no antibacterial function, complex use process, large specific surface area of inorganic antibacterial powder, etc. Production, the effect of enhancing visual aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In the present embodiment, the two-color antibacterial EVA shoes consist of the following components by weight:

[0051] EVA 5110 15 parts

[0052] EVA 7470 35 parts

[0053] Ethylene-butylene copolymer ENR7256 20 parts

[0054] 1,2-polybutadiene RB820 17 parts

[0055] Tributylphosphonium antimicrobial agent of tributylvinylbenzyl chloride-methyl methacrylate copolymer 4 parts

[0056] Chlorinated polyethylene 135B 4 parts

[0057] Foaming agent Ac 2.4 parts

[0058]Cross-linking agent BIBP 0.8 parts

[0059] Zinc stearate 1.2 parts

[0060] Stearic acid 1.2 parts

[0061] Anti-wear agent AG209 3 parts

[0063] Pigment phthalocyanine blue 0.4 parts.

[0064] The preparation method of two-color antibacterial EVA shoes, comprises steps:

[0065] Step 1: To prepare two different colors of antibacterial EVA rice, first mix other raw materials in the above formula except crosslinking agent and foaming agent for banburying, adjust the...

Embodiment 2

[0070] In the present embodiment, the preparation method of a kind of two-color antibacterial EVA shoes is identical with the preparation method in embodiment 1, difference is:

[0071] Part of the composition of antibacterial EVA material rice A is changed to: EVA 7470 50 parts, ethylene-butylene copolymer ENR7256

[0072] 20 parts, 15 parts of 1,2-polybutadiene RB830, 6 parts of tributylphosphine salt antibacterial agent of tributylvinylbenzyl chloride-methyl methacrylate copolymer, 0.8 parts of carbon black (pigment);

[0073] The pigment of antibacterial EVA material rice B is 0.2 parts of fluorescent blue.

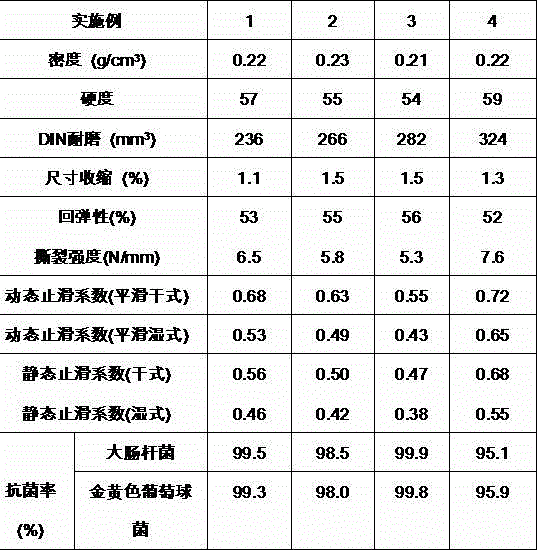

[0074] The two-color antibacterial EVA shoe that above-mentioned preparation obtains, density 0.23g / cm 3 , hardness 55, DIN wear resistance 266 mm 3 , dimensional shrinkage 1.5%, rebound rate 55%, tear strength 5.8N / mm, dynamic anti-slip coefficient smooth dry type 0.63 wet type 0.49, static anti-slip coefficient dry type 0.50 wet type 0.42, antibacterial rate again...

Embodiment 3

[0076] In the present embodiment, the preparation method of a kind of two-color antibacterial EVA shoes is identical with the preparation method in embodiment 1, difference is:

[0077] Part of the composition of antibacterial EVA material rice A is changed to: 15 parts of EVA E210F, 35 parts of EVA PA470, 20 parts of ethylene-butylene copolymer ENR7086, 6 parts of quaternary ammonium salt polymer antibacterial agent ASQA, 3 parts of chlorinated polyethylene, 10 parts of talcum powder, obtain antibacterial EVA material rice A;

[0078] The two-color antibacterial EVA shoe that above-mentioned preparation obtains, density 0.21g / cm 3 , hardness 54, DIN wear resistance 282 mm 3 , dimensional shrinkage 1.5%, rebound rate 56%, tear strength 5.3N / mm, dynamic anti-slip coefficient smooth dry type 0.55 wet type 0.43, static anti-slip coefficient dry type 0.47 wet type 0.38, antibacterial rate against Escherichia coli 99.9%, The antibacterial rate against Staphylococcus aureus is 99....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Wear-resistant | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com