Preparation method of hexagonal boron nitride ceramic material stable silver carbonate semiconductor

A technology of hexagonal boron nitride and ceramic materials, applied in the direction of light water/sewage treatment, etc., can solve the problems of low product yield and specific surface, unstable properties of reaction precursors, environmental and safety threats, etc. Short time, less environmental pollution, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1 6

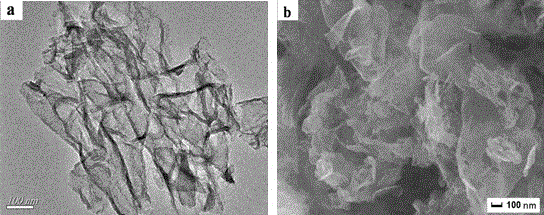

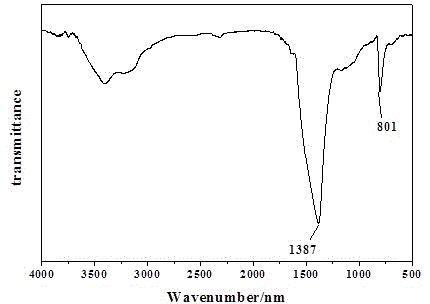

[0039] Implementation Case 1 Preparation of Hexagonal Boron Nitride and Boron Nitride / Silver Carbonate Nanocomposite

[0040] CO(NH at a molar ratio of 24:1 2 ) 2 and H 3 BO 4 Put it into a beaker, dissolve it completely in deionized water under the action of ultrasound, then evaporate the solution to dryness in a water bath at 65°C under magnetic stirring, then put the evaporated sample in an alumina crucible, and place it in a tube In a nitrogen atmosphere, the temperature was raised to 900°C at a rate of 5°C / min and kept for 5 hours. After the temperature of the tube furnace dropped to room temperature, the sample was taken out and ground to obtain white boron nitride powder.

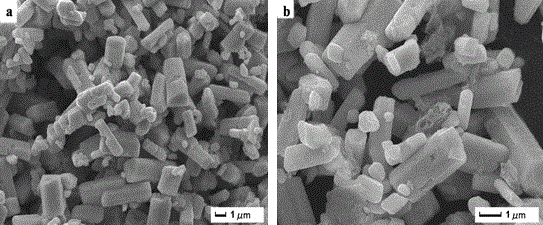

[0041] Take 0.015g of graphite phase boron nitride and uniformly disperse in deionized water under the action of ultrasound, then add 0.6163g of silver nitrate to obtain a uniformly dispersed solution under the action of ultrasound, add 1mL of 0.5mol / L ammonia solution, after stirring for 20mi...

Embodiment example 2 6

[0042] Implementation Case 2 Preparation of Hexagonal Boron Nitride and Boron Nitride / Silver Carbonate Nanocomposite

[0043] CO(NH at a molar ratio of 24:1 2 ) 2 and H 3 BO 4 Put it into a beaker, dissolve it completely in deionized water under the action of ultrasound, then evaporate the solution to dryness in a water bath at 65°C under magnetic stirring, then put the evaporated sample in an alumina crucible, and place it in a tube In a nitrogen atmosphere, the temperature was raised to 700°C at a rate of 3°C / min and kept for 3 hours. After the temperature of the tube furnace dropped to room temperature, the sample was taken out and ground to obtain white boron nitride powder.

[0044] Take 0.03g of graphite phase boron nitride and uniformly disperse in deionized water under the action of ultrasound, then add 0.6163g of silver nitrate to obtain a uniformly dispersed solution under the action of ultrasound, add 0.5mL of 0.5mol / L ammonia solution, after stirring for 20min...

Embodiment example 3 6

[0045] Implementation Case 3 Preparation of Hexagonal Boron Nitride and Boron Nitride / Silver Carbonate Nanocomposite

[0046] CO(NH at a molar ratio of 24:1 2 ) 2 and H 3 BO 4 Put it into a beaker, dissolve it completely in deionized water under the action of ultrasound, then evaporate the solution to dryness in a water bath at 65°C under magnetic stirring, then put the evaporated sample in an alumina crucible, and place it in a tube In a nitrogen atmosphere, the temperature was raised to 1100°C at a rate of 8°C / min and kept for 7 hours. After the temperature of the tube furnace dropped to room temperature, the sample was taken out and ground to obtain white boron nitride powder.

[0047] Take 0.0088g of graphite phase boron nitride and uniformly disperse in deionized water under the action of ultrasound, then add 0.6163g of silver nitrate to obtain a uniformly dispersed solution under the action of ultrasound, add 1.5mL of 0.5mol / L ammonia solution, after stirring for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com