Method for synthesizing 1, 4-diketone compound without catalyst

A technology for diketones and compounds, which is applied in the field of catalyst-free one-step synthesis, can solve the problems of harsh reaction conditions, limited substrate range, and difficulty in obtaining raw materials, and achieves the effects of less side reactions, low cost, and easy availability of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

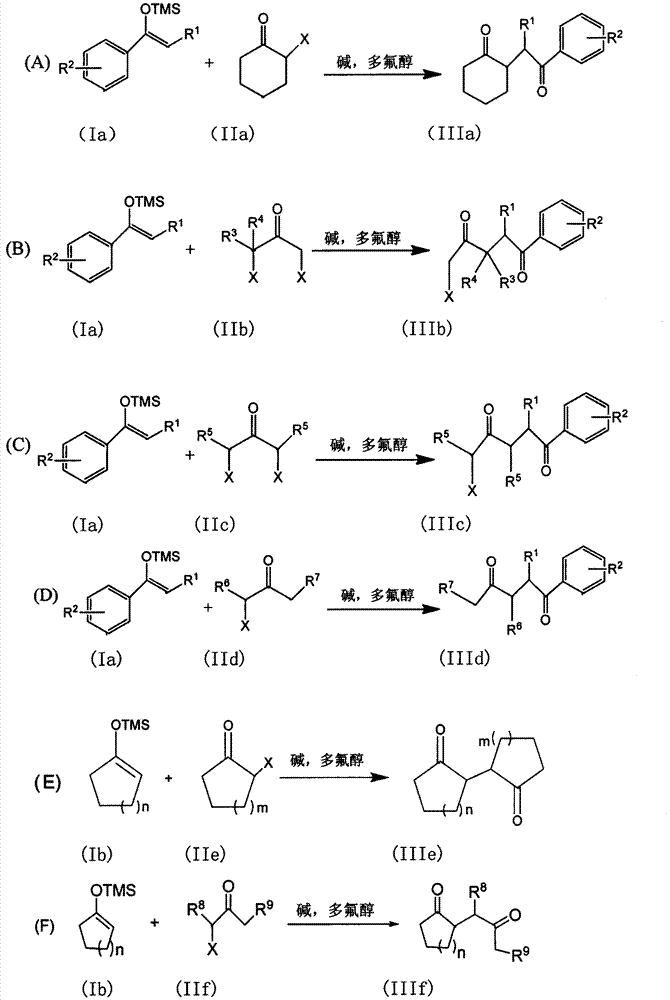

Image

Examples

Embodiment 1

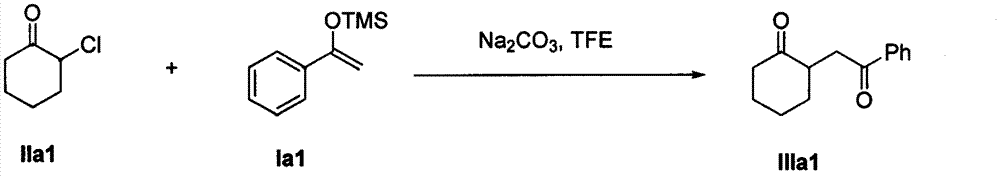

[0026] Example 1: Reaction of 2-chlorocyclohexanone IIa1 with enol silyl ether Ia1

[0027]

[0028] In a 50mL round-bottomed flask, under stirring, add 2-chlorocyclohexanone IIa1 (10mmol), sodium carbonate (20mmol) and 15mL trifluoroethanol, then slowly enol silyl ether Ia1 (30mmol) through a constant pressure dropping funnel Drop into a round bottom flask. The reaction mixture was stirred at room temperature for 12 h. After TCL monitored the complete reaction of 2-chlorocyclohexanone IIa1, the trifluoroethanol solvent was recovered by distillation under reduced pressure, and the remaining mixture was added with 15 mL of water and 15 mL of dichloromethane and stirred at room temperature for 0.5 h, then extracted with dichloromethane. The extract was dried with anhydrous sodium sulfate and concentrated; then the mixed solvent of petroleum ether and ethyl acetate (volume ratio: 10:1) was used as the eluent to carry out silica gel column chromatography for separation and pur...

Embodiment 2

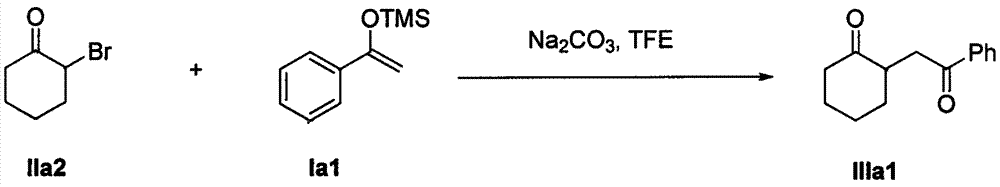

[0030] Example 2: Reaction of 2-bromocyclohexanone IIa2 with enol silyl ether Ia1

[0031]

[0032] In a 50mL round-bottomed flask, under stirring, add 2-bromocyclohexanone IIa2 (10mmol), sodium carbonate (15mmol) and 15mL trifluoroethanol, then slowly enol silyl ether Ia1 (30mmol) through a constant pressure dropping funnel Drop into a round bottom flask. The reaction mixture was stirred at room temperature for 12 h. After the reaction of 2-bromocyclohexanone IIa2 was monitored by TCL, the trifluoroethanol solvent was recovered by distillation under reduced pressure, and the remaining mixture was added with 15 mL of water and 15 mL of dichloromethane and stirred at room temperature for 0.5 h, then extracted with dichloromethane. The extract was dried with anhydrous sodium sulfate and concentrated; then the mixed solvent of petroleum ether and ethyl acetate (volume ratio: 10:1) was used as the eluent to carry out silica gel column chromatography for separation and purifica...

Embodiment 3

[0033] Embodiment 3: 2-bromocyclohexanone IIa2 reacts with enol silyl ether Ia2

[0034]

[0035] In a 50mL round-bottomed flask, under stirring, add 2-bromocyclohexanone IIa2 (10mmol), potassium carbonate (15mmol) and 15mL hexafluoroisopropanol, and then put enol silyl ether Ia2 (30mmol) through constant pressure drop The funnel drips slowly into the round bottom flask. The reaction mixture was stirred at 0°C. After the reaction of 2-bromocyclohexanone IIa2 was monitored by TCL, the hexafluoroisopropanol solvent was recovered by distillation under reduced pressure, and the remaining mixture was added with 15 mL of water and 15 mL of dichloromethane and stirred at room temperature for 0.5 h, then Extract with dichloromethane. The extract was dried with anhydrous sodium sulfate and concentrated; then the mixed solvent of petroleum ether and ethyl acetate (volume ratio: 10:1) was used as the eluent to carry out silica gel column chromatography for separation and purification t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com