High-strength corrosion-resistant wood-plastic composite material for plates and preparation method thereof

A wood-plastic composite material, high-strength technology, applied in the field of composite materials, can solve the problems of water resistance, poor corrosion resistance and aging resistance, low mechanical properties, large consumption of wood, etc., to enhance strength and corrosion resistance, improve anti-aging Aging performance, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A high-strength anti-corrosion wood-plastic composite material for boards, which is prepared from the following raw materials in parts by weight (kg): wood powder 100, chlorinated polyethylene 20, polybutadiene rubber 8, dibutyl adipate Glyceride 2, magnesium powder 3, antimony trisulfide 5, nano boehmite 10, bis(dioctyloxypyrophosphate) ethylene titanate 3, hollow microspheres 14, high borate calcium borate 6, 4-Hydroxymethyl-2,6-di-tert-butylphenol 3, calcium lauricate 2, dimethyl terephthalate 10, ethylene-octene copolymer 5, triphenyl phosphite 6, activated calcium carbonate 40. Gypsum whiskers 4. Ammonium polyphosphate 12. Sugarcane wax 5. Dimethicone oil 7.

[0015] A method for preparing a high-strength corrosion-resistant wood-plastic composite material for boards, comprising the following steps:

[0016] (1) Put the wood flour into the internal mixer and raise the temperature to 80-100°C to reduce the water content to below 3%, add dimethyl terephthalate an...

Embodiment 2

[0020] A high-strength anti-corrosion wood-plastic composite material for boards, characterized in that it is prepared from the following raw materials in parts by weight (kg): wood powder 110, chlorinated polyethylene 25, polybutadiene rubber 9, adipic acid Dibutyl diglyceride 3, magnesium powder 4, antimony trisulfide 7.5, nano boehmite 12.5, bis(dioctyloxypyrophosphate) ethylene titanate 4, hollow microspheres 16, high boron Calcium borate 6.5, 4-hydroxymethyl-2,6-di-tert-butylphenol 3.5, calcium lauricate 2.5, dimethyl terephthalate 11, ethylene-octene copolymer 6, triphenyl phosphite 7 , Activated calcium carbonate 45, gypsum whiskers 5, ammonium polyphosphate 13, sugarcane wax 7, simethicone 7.5.

[0021] The preparation method is the same as in Example 1.

Embodiment 3

[0023] A high-strength anti-corrosion wood-plastic composite material for boards, prepared from the following raw materials in parts by weight (kg): wood powder 120, chlorinated polyethylene 30, polybutadiene rubber 10, dibutyl adipate Glyceride 4, magnesium powder 5, antimony trisulfide 10, nano boehmite 15, bis(dioctyloxypyrophosphate) ethylene titanate 5, hollow microspheres 18, high borate calcium borate 7, 4-Hydroxymethyl-2,6-di-tert-butylphenol 4, Calcium Laurate 3, Dimethyl Terephthalate 12, Ethylene-Octene Copolymer 7, Triphenyl Phosphite 8, Activated Calcium Carbonate 50. Gypsum whiskers 6. Ammonium polyphosphate 14. Sugarcane wax 9. Dimethicone oil 8.

[0024] The preparation method is the same as in Example 1.

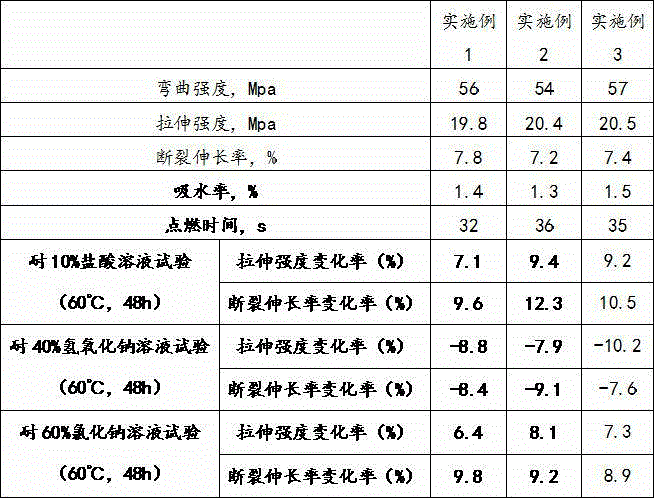

[0025] The performance test results of the high-strength anti-corrosion wood-plastic composite material for plates prepared in the above-mentioned embodiments 1-3 are shown in the following table:

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com