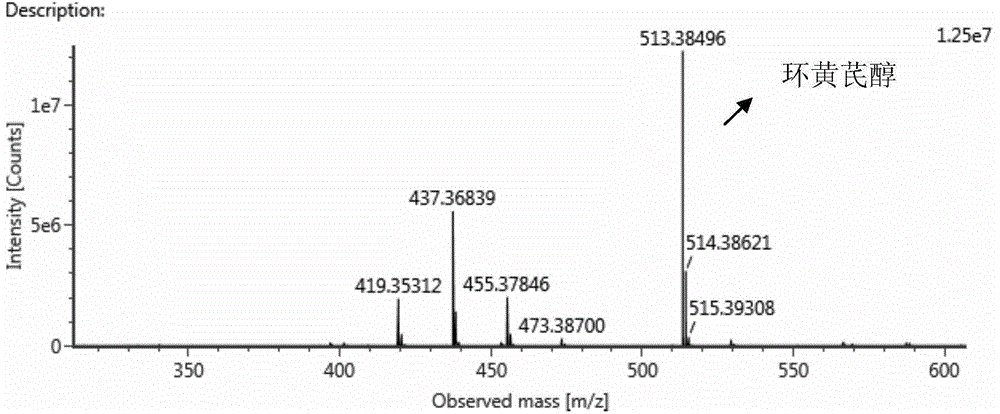

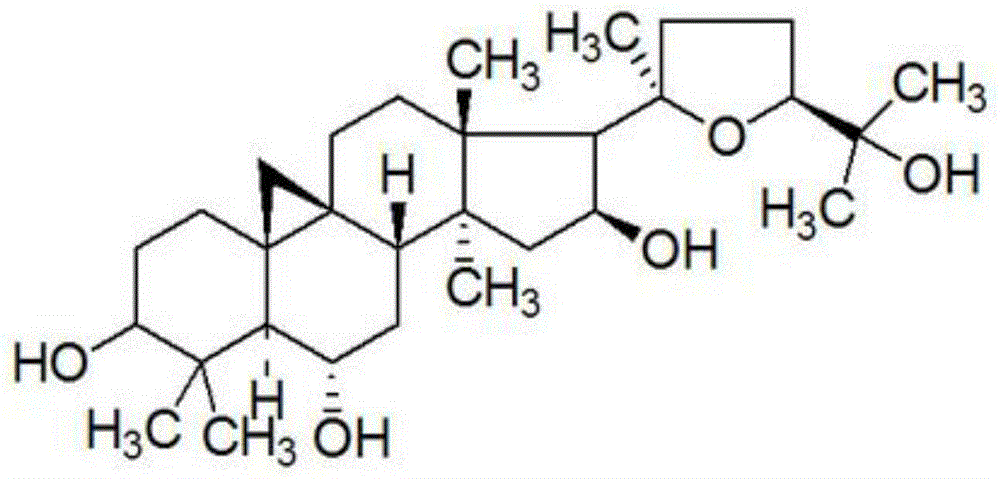

Method for preparation of Cycloastragenol by sulfuric acid hydrolysis

A technology of hydrolysis of cycloastragenol and sulfuric acid, which is applied in the field of medicine and chemical industry, and can solve the problems of complex operation, cumbersome steps, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation of crude extract of astragaloside IV: After pulverizing the traditional Chinese medicine Astragalus, take 10g of Astragalus and add it to methanol with a solid-liquid mass ratio of 1:10, then add 2% ammonia water with a mass fraction of 28% according to the mass ratio of methanol, and place in a flask The rotor was magnetically stirred, and the temperature was set at 65°C. When the first drop of condensate appeared on the condenser, the timing was started. The time for one reflux was set to 2h, and each sample was refluxed twice for extraction. After refluxing and filtering, the filtrate was spin-dried to obtain the crude extract of astragaloside IV, and the purity of astragaloside IV was 0.28% as measured by HPLC.

[0019] Preparation of cycloastragenol by acid hydrolysis: Accurately weigh 5.00 g of the crude extract of astragaloside IV, add it to 50 ml of 5% sulfuric acid solution, and react in a closed reaction kettle at 130° C. for 6 h. After the reactio...

Embodiment 2

[0022] Preparation of crude extract of astragaloside IV: Take 10 g of astragalus powder and add it to methanol with a solid-liquid mass ratio of 1:10, at a temperature of 65° C., add methanol with a mass fraction of 2% and ammonia water with a mass fraction of 28%, and place a rotor in the flask for Magnetic stirring, start timing when the first drop of condensate appears on the condenser, the time of one reflux is set to 2h, and each sample is refluxed twice for extraction. After refluxing and filtering, the filtrate was spin-dried to obtain the crude extract of astragaloside IV, and the purity of astragaloside IV was 0.31% as measured by HPLC.

[0023] Preparation of cycloastragenol by acid hydrolysis: take 5.00 g of the crude extract of glycosides, add 50 ml of sulfuric acid solution with a mass fraction of 5%, and react in a closed reaction kettle at 130°C for 6 hours. After the reaction is completed, use a mass fraction of 10% of ammonia for neutralization. Take out the ...

Embodiment 3

[0026] Preparation of the crude extract of astragaloside IV: take 100 g of astragalus powder and extract it under reflux with methanol, the mass ratio of solid to liquid is 1:10, add 2% by mass of ammonia water with a mass fraction of 28%, the temperature is 65°C, and carry out magnetic stirring. The time was set to 2h, and reflux was performed twice. After filtration, the filtrate was rotary evaporated to obtain the crude extract of glycoside A, and the purity of glycoside A was 0.25% as measured by HPLC.

[0027] Preparation of cycloastragenol by acid hydrolysis: weigh 20.00 g of the crude extract of glycoside A, add 200 ml of sulfuric acid solution with a mass fraction of 5% in a closed reaction kettle, and react at 130° C. for 6 hours. After the reaction, neutralize with 10% ammonia water. Take out the material in the kettle and place it in a beaker, add 200ml of chloroform, shake well and let it stand to remove impurities in the chloroform layer. Add 200ml of n-butanol,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com