A kind of polysulfonic acid functionalized mesoporous polymer solid acid catalyst and its preparation method and application

A technology of solid acid catalysts and polymers, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low acid density and small specific surface area, etc. Achieve the effects of low corrosion loss, high specific surface area and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

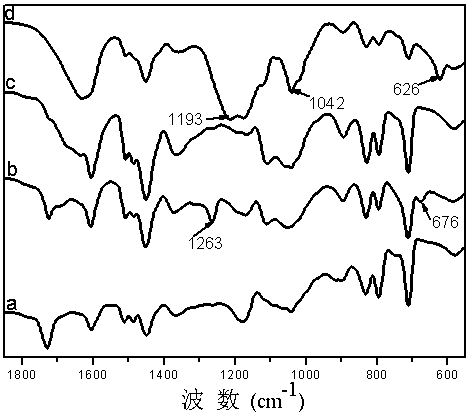

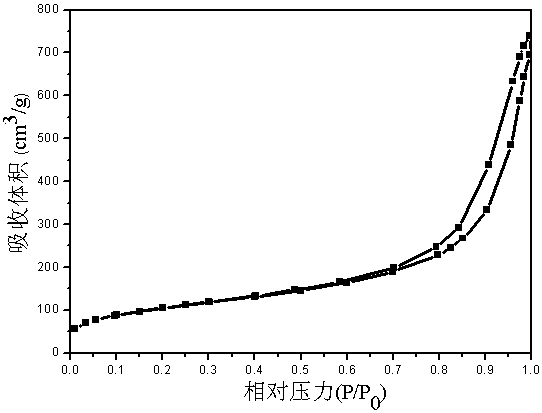

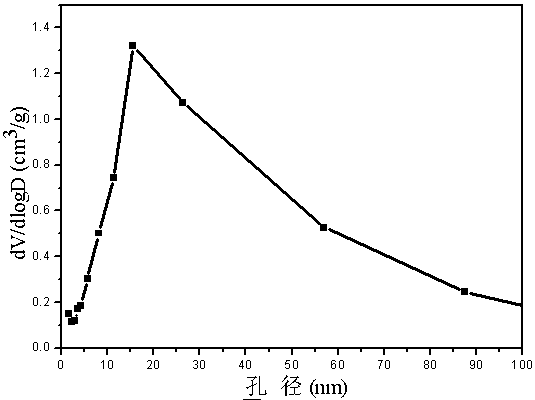

[0045] Example 1 Synthesis of polysulfonic acid functionalized mesoporous polymer solid acid

[0046] Proceed as follows:

[0047] (1) Add 2 g of divinylbenzene and 0.05 g of azobisisobutyronitrile to a mixed solution of 2 mL of water in 20 mL of tetrahydrofuran, stir at room temperature for at least 3 h, and then transfer to a polytetrafluoroethylene substrate Heat treatment at 100°C for 24 h in a pressure reaction vessel, after the temperature dropped to room temperature, open the cover, and evaporate the solvent at room temperature to obtain polydivinylbenzene (PDVB) with mesoporous structure;

[0048] (2) Grind 2 g of mesoporous polydivinylbenzene into 200-mesh powder, add 30 mL of chloromethyl methyl ether to the powder, add 7 g of anhydrous aluminum chloride under ice bath, transfer to room temperature, Stir for 24 h. After the reaction, add water to the system, filter the product, wash with water and acetone, and dry in vacuum at 80 °C to obtain mesoporous polydivinylb...

Embodiment 2

[0051] Example 2 Application of polysulfonic acid functionalized mesoporous polymer solid acid catalyzed esterification reaction of oleic acid and methanol in preparation of biodiesel.

[0052] In autoclave, add 6.8 g methyl alcohol and 2 g oleic acid (the mol ratio of alcohol and fatty acid is 30:1), then add 0.08 g polysulfonic acid functionalization mesoporous polymer solid acid catalyst (catalyst amount is 4% of fatty acid quality %), at a temperature of 100 °C, stirred for 4 h, after the reaction, filtered, the filtrate was rotary evaporated to remove unreacted methanol, and Na 2 SO 4 Dry to obtain crude biodiesel. The conversion rate of oleic acid was calculated by acid-base titration, and the conversion rate of oleic acid was calculated to be 98.0%.

Embodiment 3

[0053] Example 3 Application of polysulfonic acid-functionalized mesoporous polymer solid acid catalyzed jatropha oil and methanol in the "one-pot" preparation of biodiesel.

[0054] Add 3.5 g methyl alcohol and 2 g Jatropha oil (the mol ratio of alcohol and Jatropha oil is 50:1) in autoclave, add 0.1 g polysulfonic acid functionalized mesoporous polymer solid acid catalyst again (catalyst amount 6% of the fatty acid mass), at a temperature of 160 °C, stirred and reacted for 8 h, after the reaction was completed, petroleum ether was added, filtered, the filtrate was separated, the supernatant was taken, and petroleum ether and unreacted methanol were removed by rotary evaporation. use Na 2 SO 4 Dry to obtain crude biodiesel. The content of biodiesel was calculated by gas chromatography, and the content of biodiesel was calculated to be 78.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com