Supported type mercury-free catalyst for chloroethylene production with acetylene hydrochlorination method

A technology of acetylene hydrochlorination and mercury catalyst, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problems such as mercury pollution of calcium carbide method PVC, To achieve the effects of prolonging catalyst life, high activity and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Weigh 0.35g of 2,4-dichloro-6-methoxy-1,3,5-triazine, dissolve it in 9ml of water, heat and stir to dissolve, add 7g of corresponding basic activated carbon carrier, stir, impregnate overnight, and dry to obtain For the treated carrier, weigh 0.0073g of chloroauric acid and 0.21g of copper chloride and dissolve them in 8.5ml of distilled water, stir to dissolve, add the treated carrier into the solution, stir, soak overnight, and place in an oven at 120°C Dry 8h. A highly active metal complex catalyst is obtained.

[0048] Evaluation conditions, put 1g of catalyst into a tubular fixed-bed reactor, dry with nitrogen for 40min at a reaction temperature of 180°C, activate with hydrogen chloride for 40min, and have an acetylene space velocity of 200h -1 , Raw gas volume flow ratio C 2 h 2 : HCl=1:1.1, reaction 12h.

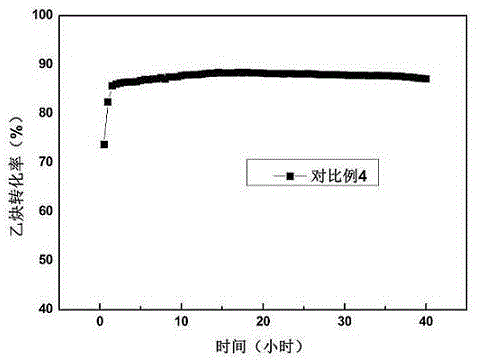

[0049] The relationship between catalyst conversion rate and time change is as follows: figure 1 Shown, the selectivity is shown in Table 1.

Embodiment 2

[0051] Weigh 0.35g of 2-chloro-4,6-diamino-1,3,5-triazine, dissolve it in 9ml of water, heat and stir to dissolve, add 7g of the corresponding basic activated carbon carrier, stir, impregnate overnight, and dry to obtain the treated For the carrier, weigh 0.0073g of chloroauric acid and 0.21g of copper chloride and dissolve them in 8.5ml of distilled water, stir to dissolve, add the treated carrier into the solution, stir, soak overnight, put in an oven and dry at 120°C for 8h . A highly active metal complex catalyst is obtained.

[0052] Evaluation conditions are the same as in Example 1.

[0053] The relationship between catalyst conversion rate and time change is as follows: figure 1 Shown, the selectivity is shown in Table 1.

Embodiment 3

[0055] Weigh 0.35g of 6-chloro-N,N-diethyl-1,3,5-triazine-2,4-diamine, dissolve in 9ml of water, heat and stir to dissolve, add 7g of corresponding basic activated carbon carrier, stir , impregnated overnight, dried to obtain the treated carrier, weighed 0.0073g chloroauric acid and 0.21g cupric chloride and dissolved in 8.5ml distilled water, stirred and dissolved, added the treated carrier into the solution, stirred, soaked overnight, put in Dry in an oven at 120°C for 8h. A highly active metal complex catalyst is obtained.

[0056] Evaluation conditions are the same as in Example 1.

[0057] The relationship between catalyst conversion rate and time change is as follows: figure 1 Shown, the selectivity is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com