Method of screening medicaments with high accuracy and high repeatability

An accurate and repeatable technology, applied in the direction of biochemical equipment and methods, microbial measurement/inspection, etc., can solve the problems of high cost of raw materials, difficulty in preparing arrays of electrospun fibers, and difficulty in electrospinning fibers, so as to ensure accuracy and repeatability, large market practical value, mature and easy-to-operate technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

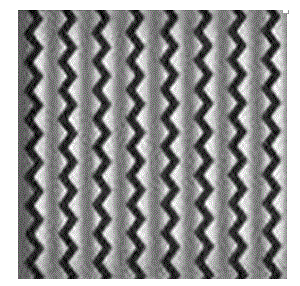

[0038] 1) Preparation of patterned fiber electrospinning receiving plate: first coat positive photoresist on the insulating glass sheet, then cover with a layer of photomask, and etch with a photoetching machine; then use DC magnetron technology to etch after etching A layer of metallic silver is deposited on the glass sheet, the shape of the deposited metallic silver is fold line shape, and the pattern width is 80 μm; finally, the remaining positive photoresist is cleaned;

[0039] 2) Preparation of patterned electrospun fibers: dissolve the medical high molecular polymer in an organic solvent, and use the resultant in step 1) as an electrospinning receiving plate to prepare patterned electrospun fibers by electrospinning technology; control the diameter of the resulting fiber to be 400 nm;

[0040] The medical high molecular polymer is polylactic acid, and the organic solvent is acetone;

[0041] 3) Place the SU-8 on the silicon wafer, use photolithography to remove the re...

Embodiment 2

[0045] 1) Preparation of patterned fiber electrospinning receiving plate: first coat positive photoresist on the insulating glass sheet, then cover with a layer of photomask, and etch with a photoetching machine; then use DC magnetron technology to etch after etching A layer of metallic silver is deposited on the glass sheet, the shape of the deposited metallic silver is a fold line shape, and the pattern width is 40 μm; finally, the remaining positive photoresist is cleaned;

[0046] 2) Preparation of patterned electrospun fibers: dissolve the medical high molecular polymer in an organic solvent, and use the resultant in step 1) as an electrospinning receiving plate to prepare patterned electrospun fibers by electrospinning technology; control the diameter of the resulting fiber to be 300 nm;

[0047] The medical polymer is polycaprolactone, and the organic solvent is acetone and dimethylformamide (9:1 v / v);

[0048] 3) Place the SU-8 on the silicon wafer, use photolithogra...

Embodiment 3

[0052] 1) Preparation of patterned fiber electrospinning receiving plate: first coat positive photoresist on the insulating glass sheet, then cover with a layer of photomask, and etch with a photoetching machine; then use DC magnetron technology to etch after etching A layer of metallic silver is deposited on the glass sheet, the shape of the deposited metallic silver is a broken line shape, and the pattern width is 20 μm; finally, the remaining positive photoresist is washed away;

[0053] 2) Preparation of patterned electrospun fibers: dissolve the medical high molecular polymer in an organic solvent, and use the resultant in step 1) as an electrospinning receiving plate to prepare patterned electrospun fibers by electrospinning technology; control the diameter of the resulting fiber to be 200 nm;

[0054] The medical high molecular polymer is polyurethane, and the organic solvent is acetone;

[0055] 3) Place the SU-8 on the silicon wafer, use photolithography to remove t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com