A kind of organosilicon electronic packaging material and preparation method thereof

An electronic packaging material, silicone technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of environmental protection, flame retardancy, unsatisfactory use effect, affecting the storage stability of rubber materials, corrosion failure, etc., and achieve good Storage stability, good adhesion, less corrosive gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

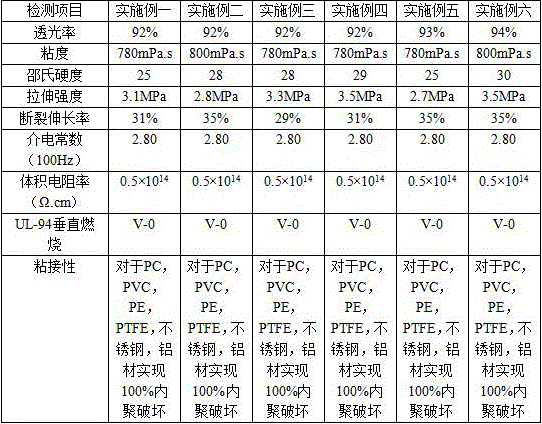

Examples

Embodiment 1

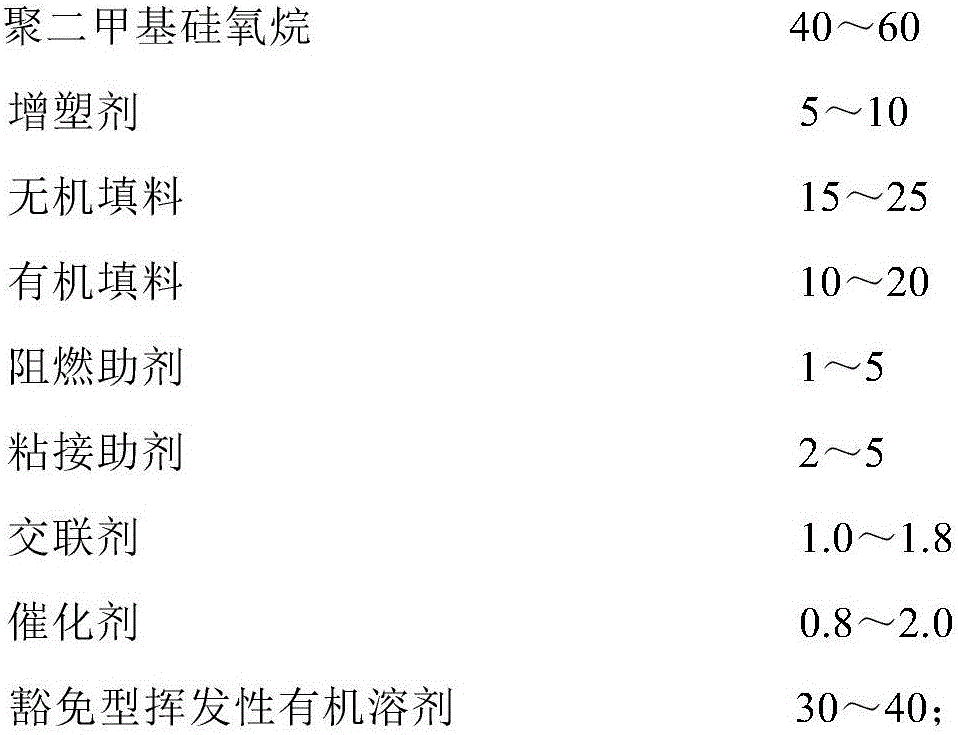

[0041] The organosilicon electronic packaging material of this embodiment consists of the following components and proportions by weight:

[0042] Methyl-terminated polydimethylsiloxane (1000cps)····· 40

[0043] Simethicone (100cps)·············································································································································

[0044] Fumed silica················ 15

[0045] Methyl MQ silicone resin························ 20

[0046] Polyborosilane················· 1

[0047] Ring Nitrogen Compounds·················3

[0048] Isopropoxysilane coupling agent... 2

[0049] Organometallic (Al) chelate 0.5

[0050] Methyltrimethoxysilane·············· 1

[0051] Dialkyltin bis(ß-diketone ester) 0.8

[0052] Hexamethyldisiloxane 30

[0053] The preparation method of the organosilicon electronic packaging material in this embodiment is as follows:

[0054] a. Stir the methyl-terminated polydimethylsiloxane and methyl MQ silicone...

Embodiment 2

[0059] The organosilicon electronic packaging material of this embodiment consists of the following components and proportions by weight:

[0060] Methyl-terminated polydimethylsiloxane (10000cps)····· 60

[0061] Simethicone (200cps) ···································································································································································

[0062] Fumed silica························· 25

[0063] Methyl MQ silicone resin···················· 15

[0064] Polyborosilane····················· 1.5

[0065] Ring Nitrogen Compounds··················3

[0066] Isooxysilane coupling agent················1

[0067] Borate compound················· 2

[0068] Methyltriethoxysilane 1.8

[0069] Polyalkoxy titanate 2.0

[0070] Octamethyltrisiloxane 40

[0071] The preparation method of the solvent-based silicone electronic packaging material in this embodiment is as follows:

[0072] a. Mix methyl-terminated polydimethylsil...

Embodiment 3

[0077] The organosilicon electronic packaging material of this embodiment differs in composition from Embodiment 1 in that:

[0078] Polyborosilane 1.5

[0079] Ring Nitrogen Compounds·······3

[0080] Isopropoxysilane coupling agent...2

[0081] Organometallic (Fe) chelates····1

[0082] The preparation method of the solvent-based silicone electronic packaging material in this embodiment is as follows:

[0083] a. Mix methyl-terminated polydimethylsiloxane and methyl MQ silicone resin at a high speed of 140r / min and disperse evenly;

[0084] b. Fumed silica was pre-baked at 140°C for 1 hour, then added in 5 times, stirred and dispersed for 35 minutes, then added simethicone, and stirred at a high speed of 100r / min to disperse evenly;

[0085] c. Add polyborosilane and ring nitrogen compound compound, isopropoxysilane coupling agent and organometallic chelate compound, stir and disperse at medium speed at 70r / min for 20min, add methyltrimethoxysilane Disperse for 10 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com