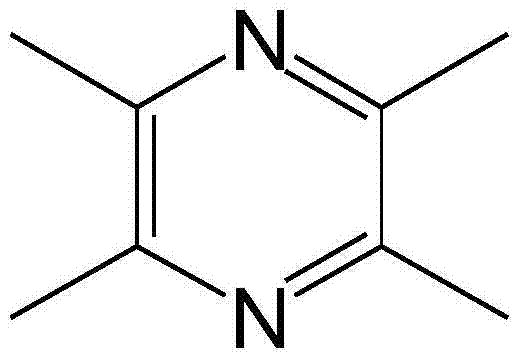

High yield preparation method of ligustrazine

A Ligustrazine, high-yield technology, applied in the field of compound preparation, can solve the problems of complex production process, large consumption of organic solvent, long reaction time, etc., and achieve the effect of simple and fast preparation process, shortened reaction time, and reduced processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

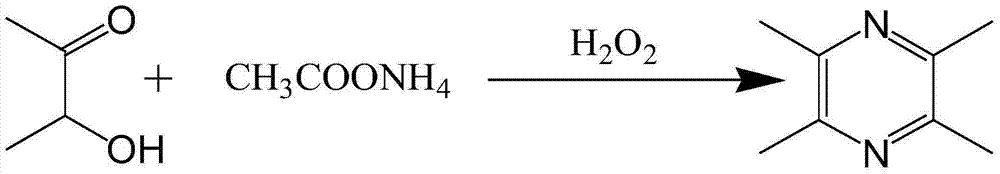

Method used

Image

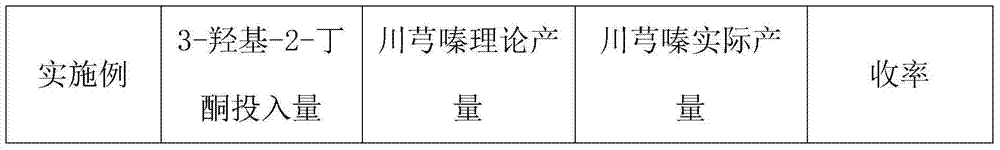

Examples

Embodiment 1

[0026] A kind of high-yield preparation method of Ligustrazine proposed by the present invention comprises the following steps:

[0027] S1, 3-hydroxyl-2-butanone, ammonium acetate, hydrogen peroxide and water are added in the reaction vessel, the content of hydrogen peroxide in the hydrogen peroxide is 29wt%, 3-hydroxyl-2-butanone, ammonium acetate and hydrogen peroxide The molar ratio is 1.1:2.4:0.6, the mass volume ratio (g / ml) of 3-hydroxy-2-butanone to water is 1.1:2, heat the mixed material in the reaction vessel to 88°C in a water bath, and keep it warm for 0.9h , cooled to room temperature to obtain a mixed solution, kept stirring during the process of heating up and keeping warm in the water bath, and the cooling rate during cooling to room temperature was 1.1°C / min;

[0028] S2. Add 1.8 mol / L sodium hydroxide solution to the mixed solution obtained in S1 until the pH is 10, then lower the temperature to 10° C., stir for 20 minutes for crystallization, filter to obtai...

Embodiment 2

[0030] A kind of high-yield preparation method of Ligustrazine proposed by the present invention comprises the following steps:

[0031] S1. Add 3-hydroxy-2-butanone, ammonium acetate, hydrogen peroxide and water into the reaction vessel. The content of hydrogen peroxide in the hydrogen peroxide is 33wt%. The temperature of the mixed material in the reaction vessel is raised to 80° C. After h, be cooled to room temperature to obtain mixed solution, keep stirring in the process of heating up and insulated;

[0032] S2. Add 1.9mol / L sodium hydroxide solution to the mixed solution obtained in S1 until the pH is 9.7, then cool down to 12°C, stir for 17min to carry out crystallization, filter to obtain a filter cake, wash the filter cake with water to obtain Ligustrazine, wherein the water The volume-to-mass ratio (ml / g) of 3-hydroxy-2-butanone in S1 is 1:1.

Embodiment 3

[0034] A kind of high-yield preparation method of Ligustrazine proposed by the present invention comprises the following steps:

[0035] S1, 3-hydroxyl-2-butanone, ammonium acetate, hydrogen peroxide and water are added in the reaction vessel, the content of hydrogen peroxide in the hydrogen peroxide is 32wt%, 3-hydroxyl-2-butanone, ammonium acetate and hydrogen peroxide The molar ratio is 0.9:2.6:0.6, the mass volume ratio (g / ml) of 3-hydroxy-2-butanone to water is 0.9:3, heat the mixed material in the reaction vessel to 82°C in a water bath, and keep it warm for 1.1h , cooled to room temperature to obtain a mixed solution, kept stirring during the process of heating up and keeping warm in the water bath, and the cooling rate during cooling to room temperature was 0.9°C / min;

[0036] S2. Add 2.1 mol / L sodium hydroxide solution to the mixed solution obtained in S1 until the pH is 9, then lower the temperature to 15° C., stir for 10 minutes for crystallization, filter to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com