Diamond-cubic boron nitride type universal superhard cutter material, cutter and preparation method of material

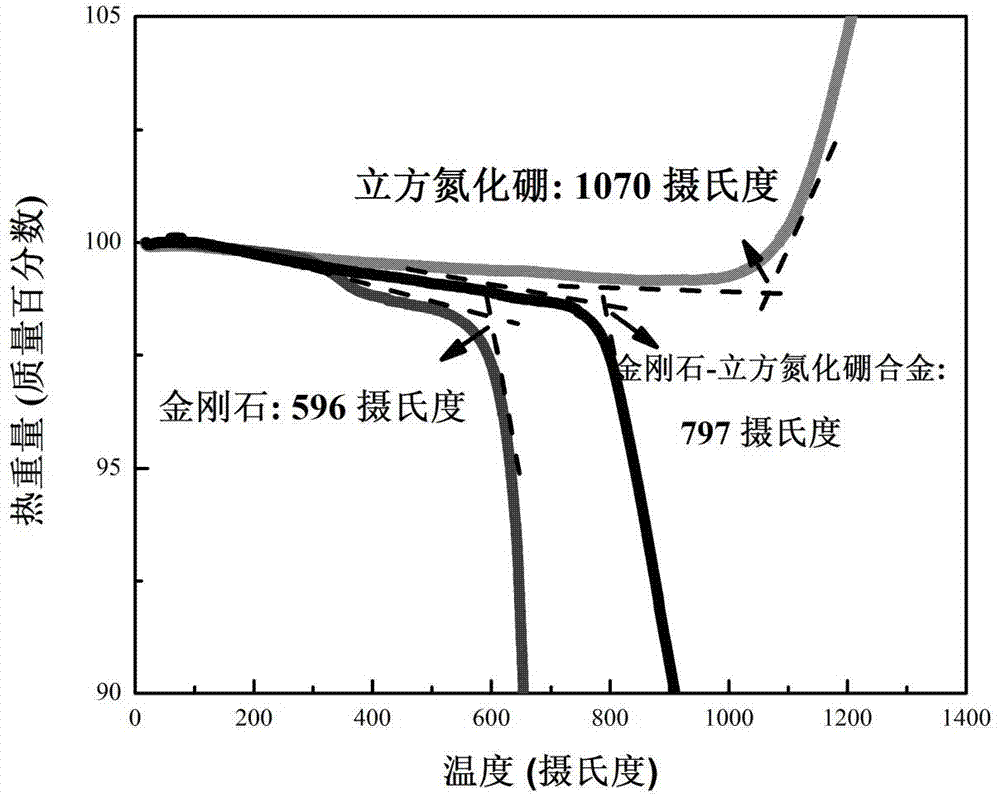

A technology of cubic boron nitride and tool materials, applied in chemical instruments and methods, methods of chemically changing substances by using atmospheric pressure, chemical/physical processes, etc., can solve the problem of high-speed cutting of iron group metals and poor thermal stability and other problems, to achieve the effect of eliminating insufficient high temperature stability, high thermal stability, and uniform grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) material preparation

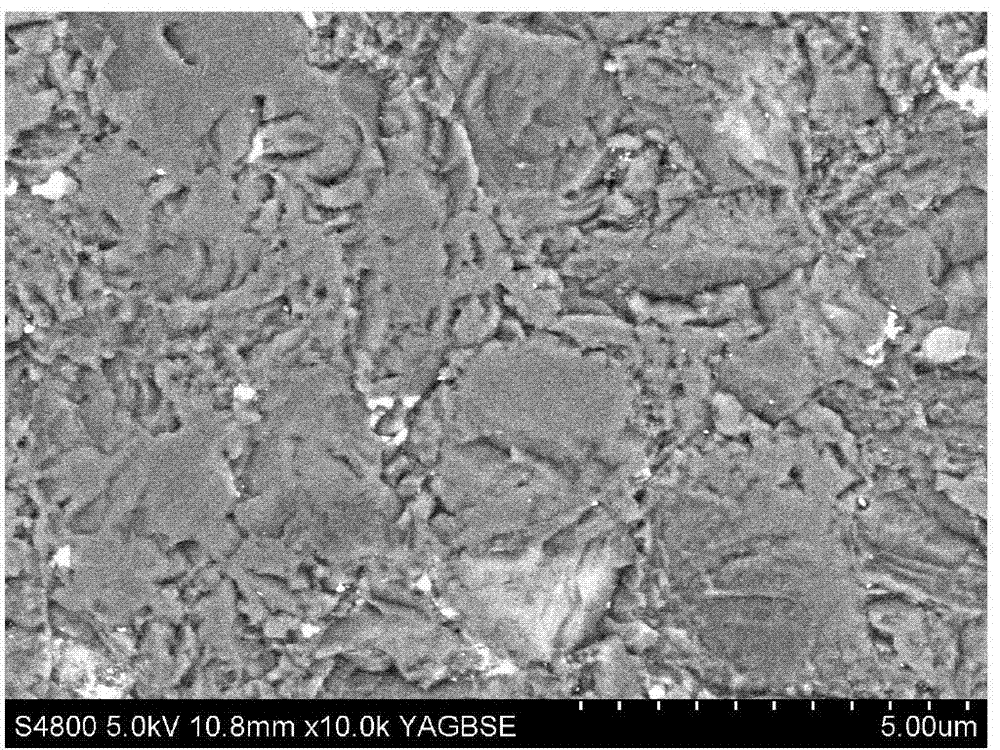

[0038] The crystal grains are diamond with an average particle size of 2 μm and cubic boron nitride crystallites with an average particle size of 2 μm, forming a steel alloy substrate.

[0039] (2) Raw material processing and molding

[0040] Mix 5 parts of diamond micropowder and 5 parts of cubic boron nitride micropowder by weight, first treat with 5 parts of surface treatment agent sulfuric acid, dissolve the impurities in the initial material at room temperature, wash with deionized water until neutral, and then Drying; wet mixing with 10 parts of alcohol, and then mixing under ultrasonic vibration with a power of 20W, in a vacuum of 4x10 -3Pa, the temperature is 1000°C, treated for 1 hour, and pre-pressed for 5 minutes at room temperature and pressure of 10 MPa without adding any binder.

[0041] (3) High pressure sintering

[0042] Put the sintering unit of the pre-pressed blank in step (2) into a high-pressure device, sinter and stre...

Embodiment 2

[0046] (1) material preparation

[0047] Diamond with an average particle size of 0.5 μm and cubic boron nitride crystallites with an average particle size of 0.5 μm form a cemented carbide substrate.

[0048] (2) Raw material processing and molding

[0049] Mix 4 parts of diamond micropowder and 6 parts of cubic boron nitride micropowder by weight, first treat with 5 parts of surface treatment agent hydrochloric acid, dissolve the impurities in the initial material at room temperature, wash with deionized water until neutral, and dry Dry; wet mix with 16 parts of alcohol, and then mix under ultrasonic vibration with a power of 20W, in a vacuum of 4x10 -3 Pa, the temperature is 1000°C, treated for 2 hours, and pre-pressed for 5 minutes at room temperature and a pressure of 10 MPa without adding any binder.

[0050] (3) High pressure sintering

[0051] Put the sintering unit assembled with the pre-pressed blank in step (2) into a high-pressure device, sinter and strengthen a...

Embodiment 3

[0055] (1) material preparation

[0056] Diamond with an average particle size of 8 μm and cubic boron nitride crystallites with an average particle size of 0.5 μm form a cemented carbide substrate.

[0057] (2) Raw material processing and molding

[0058] Mix 9 parts of diamond micropowder and 1 part of cubic boron nitride micropowder by weight, first treat with 5 parts of surface treatment agent hydrofluoric acid, dissolve impurities in the initial material at a temperature of 100°C, and wash with deionized water to medium properties, drying; wet mixing with 16 parts of alcohol, and then mixing with a power of 20W ultrasonic vibration, in a vacuum of 4x10 -3 Pa, the temperature is 1200°C, treated for 1 hour, and pre-pressed for 5 minutes at room temperature and pressure of 10 MPa without adding any binder.

[0059] (3) High pressure sintering

[0060] Put the sintering unit assembled with the pre-pressed blank in step (2) into a high-pressure device, sinter and strengthen...

PUM

| Property | Measurement | Unit |

|---|---|---|

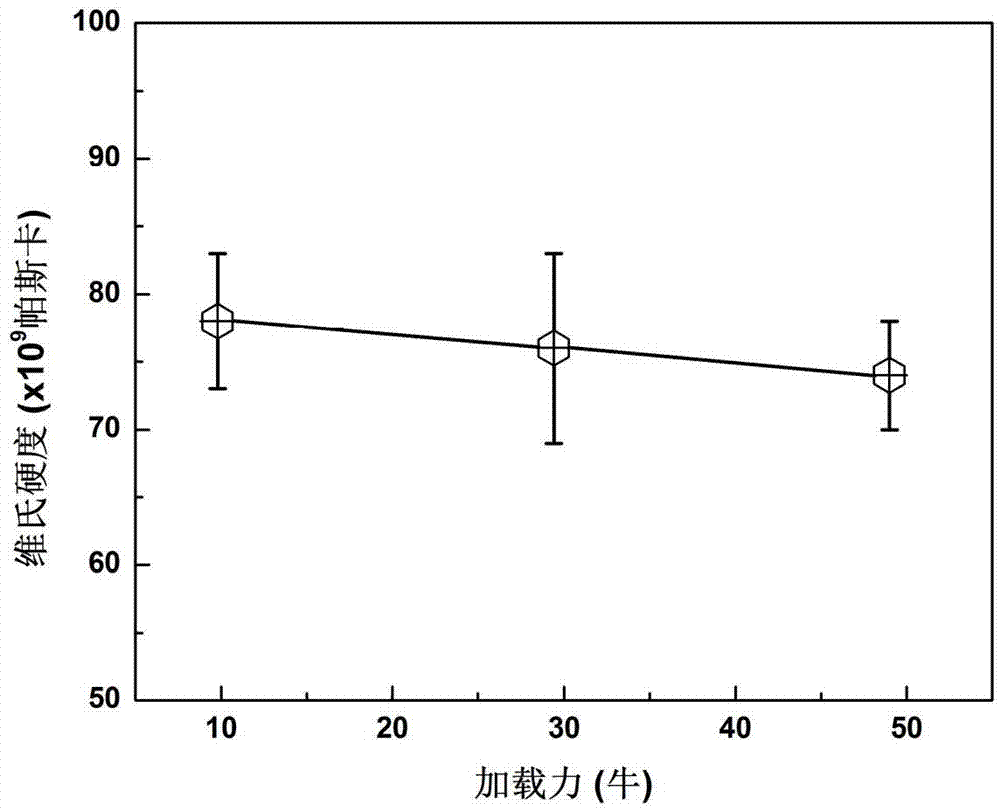

| Vickers hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com