Inorganic/organic composite proton exchange membrane and production method thereof

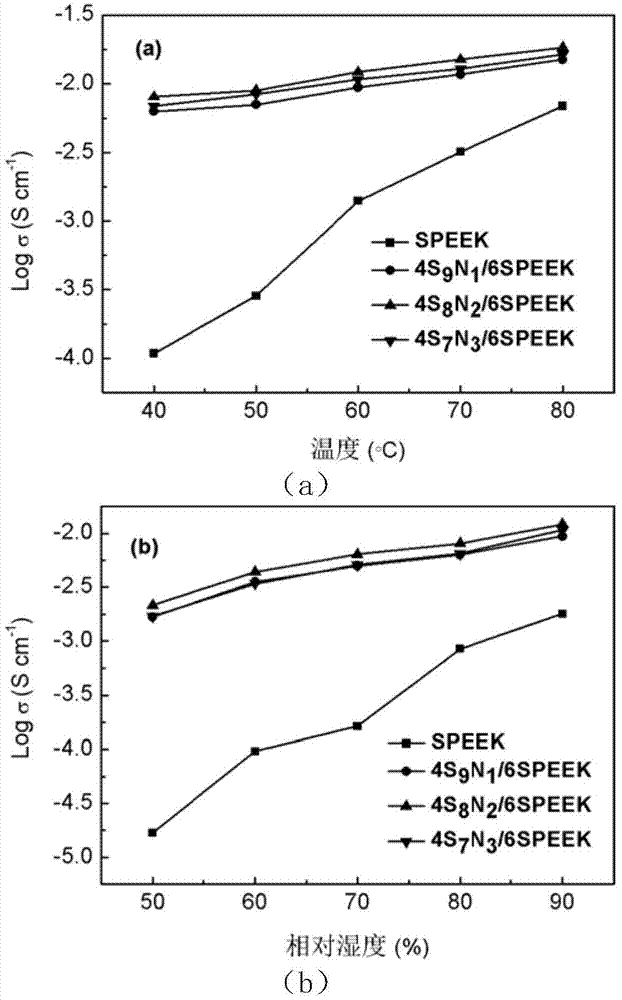

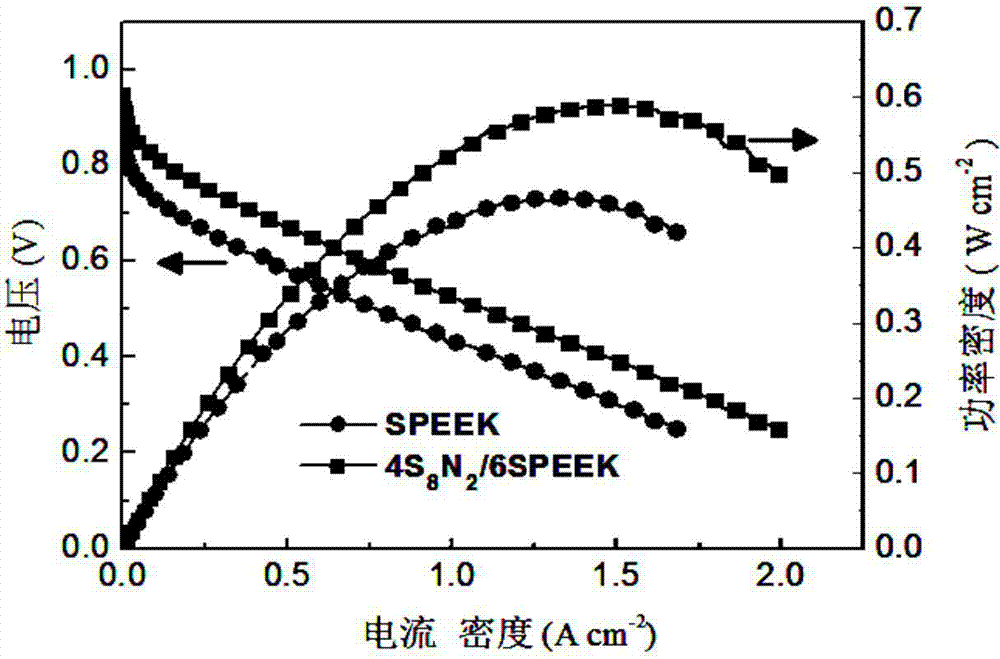

A proton exchange membrane and organic technology, applied in the field of inorganic/organic composite proton exchange membrane and its preparation, can solve the problems of low output power density of fuel cells, inability to apply hot pressing process, low mechanical strength, etc., to achieve improved durability, The effect of low equipment requirements and overall cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

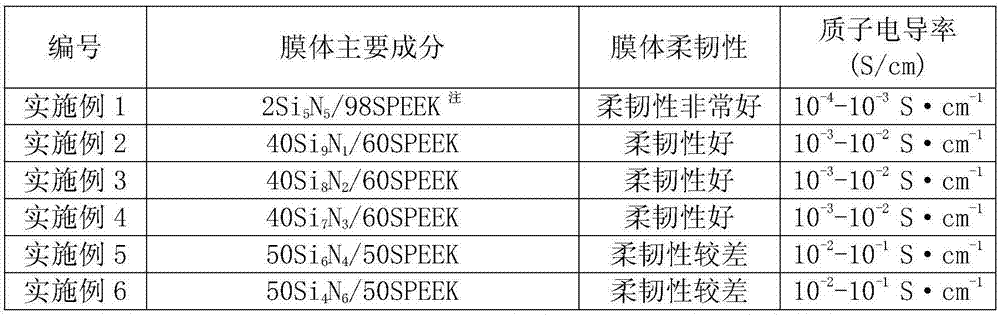

Embodiment 1

[0028] Step 1: Preparation of SiO by Modified Sol-Gel Method 2 -Nafion glass powder: firstly mix tetraethyl orthosilicate (TEOS), deionized water and hydrochloric acid in a ratio of 1:4:4×10 -3 The molar ratio was mixed and stirred at room temperature for 20 min to obtain a homogeneous sol. Then Nafion resin solution according to 50wt% SiO 2 The mass percentage of -50wt% Nafion was slowly added to the above sol and continued to stir for 20min. The obtained product was transferred to a petri dish and placed at room temperature to form a gel. Then the gel was heat-treated under water vapor at 100 °C for 480 h to obtain SiO 2 -Nafion glass pieces, crushed into glass powder for later use.

[0029] Step 2: Dissolving sulfonated polyether ether ketone (SPEEK) in dimethylformamide (DMF) to obtain a sulfonated polyether ether ketone (SPEEK) (15 wt %) solution.

[0030] Step 3: with step 1 gained glass powder and step 2 gained solution, by 2wt% (5SiO 2 -5Nafion)-98wt% SPEEK mass ...

Embodiment 2

[0033] Step 1: Preparation of SiO by Modified Sol-Gel Method 2 -Nafion glass powder: firstly mix tetraethyl orthosilicate (TEOS), deionized water and hydrochloric acid in a ratio of 1:4:4×10 -3 The molar ratio was mixed and stirred at room temperature for 20 min to obtain a homogeneous sol. Then Nafion resin solution according to 90wt% SiO 2 The mass percentage of -10wt% Nafion was slowly added to the above sol and continued to stir for 20min. The obtained product was transferred to a Teflon Petri dish and left at room temperature to form a gel. Then the gel was heat-treated under water vapor at 140 °C for 24 h to obtain SiO 2 -Nafion glass pieces, crushed into glass powder for later use.

[0034] Step 2: Sulfonated polyether ether ketone (SPEEK) was dissolved in dimethylacetamide (DMAc) to obtain a sulfonated polyetheretherketone (SPEEK) (15 wt %) solution.

[0035] Step 3: with step 1 gained glass powder and step 2 gained solution, by 40wt% (9SiO 2 -1Nafion)-60wt% SPEE...

Embodiment 3

[0038] Step 1: Preparation of SiO by Modified Sol-Gel Method 2 -Nafion glass powder: firstly mix tetraethyl orthosilicate (TEOS), deionized water and hydrochloric acid in a ratio of 1:4:4×10 -3 The molar ratio was mixed and stirred at room temperature for 20 min to obtain a homogeneous sol. Then Nafion resin solution according to 80wt% SiO 2 -20wt% Nafion mass percentage was slowly added to the above sol and continued to stir for 20min. The obtained product was transferred to a Teflon Petri dish and left at room temperature to form a gel. Then the gel was heat-treated under water vapor at 140 °C for 24 h to obtain SiO 2 -Nafion glass pieces, crushed into glass powder for later use.

[0039] Step 2: Sulfonated polyether ether ketone (SPEEK) was dissolved in dimethylacetamide (DMAc) to obtain a sulfonated polyetheretherketone (SPEEK) (15 wt %) solution.

[0040] Step 3: with step 1 gained glass powder and step 2 gained solution, by 40wt% (8SiO 2 -2Nafion)-60wt% SPEEK mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com