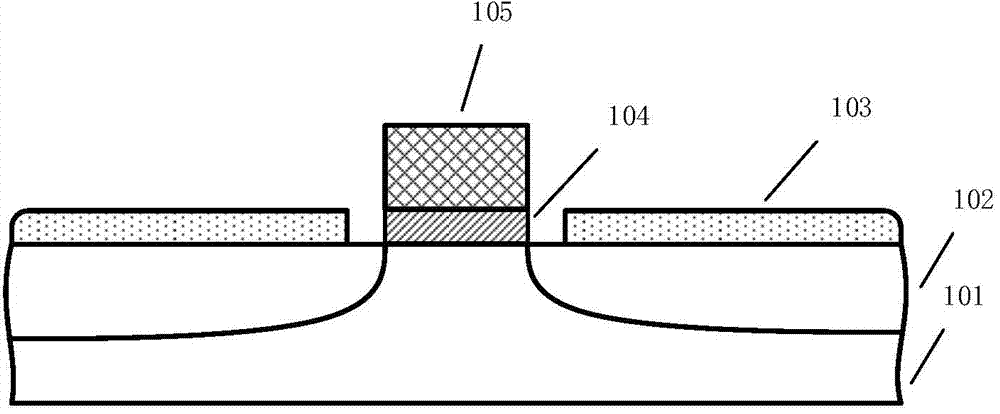

Gallium-antimonide-based semiconductor device provided with interface passivation layer and preparation method thereof

A gallium antimonide-based, passivation layer technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of low interface quality and poor device performance, and achieve reduced defect density and interface state density. Reduce and improve the effect of media quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]A method for preparing a gallium antimonide-based semiconductor device with an interface passivation layer based on claim 1, comprising the following steps:

[0039] Step 1, cleaning the gallium antimonide substrate surface to remove surface contamination and natural oxide layer;

[0040] Step 2, selectively implanting ions in the surface area of the substrate, annealing and activating, forming a second conductivity type impurity implantation layer, and evaporating source and drain contact metals in the corresponding areas;

[0041] Step 3, deposit the gate dielectric, and immediately transfer it to the plasma chamber for plasma bath treatment to form an interface passivation layer;

[0042] Step 4, evaporating the gate metal and performing subsequent processes of the semiconductor device.

[0043] In the first step, the gallium antimonide substrate cleaning includes organic solution cleaning and / or pickling.

[0044] In the second step, the implanted ions are Si, Mg...

example

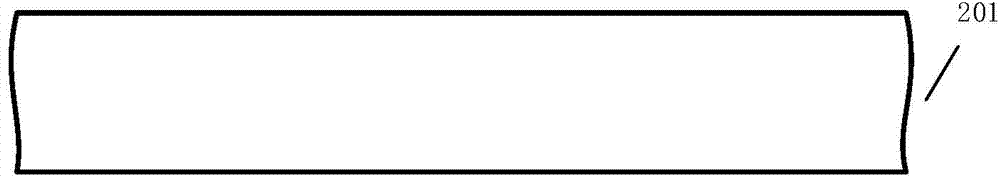

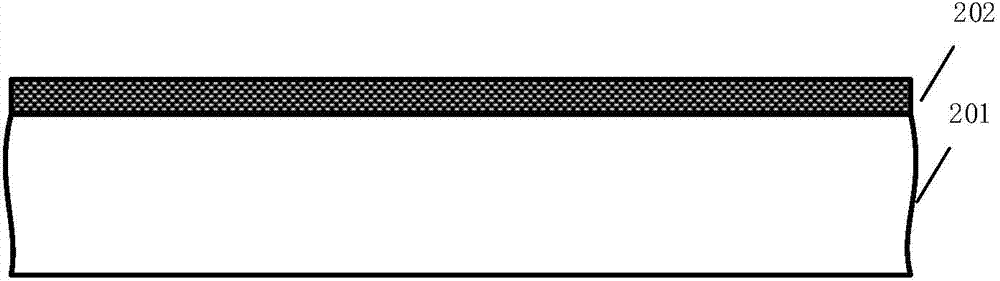

[0053] A schematic diagram of a typical preparation process flow of a GaSb-based semiconductor device with an interface passivation layer, as shown in Figure 2, wherein:

[0054] Figure 2A It is a gallium antimonide substrate (201) after organic cleaning and pickling. For organic cleaning, use acetone and ethanol to wash alternately several times, and then rinse repeatedly with deionized water to remove oil and organic pollutants on the substrate; then pickle with a hydrochloric acid solution with a concentration of 1% to 36% by mass Soak for 1-10 minutes, then rinse with deionized water repeatedly, and blow dry with nitrogen to remove the natural oxide layer. The purpose of cleaning is to remove organic and inorganic pollutants, metal particles, natural oxide layer, etc. on the substrate, but it is not limited to the above cleaning methods.

[0055] Figure 2B Al 2 o 3 , SiO 2 or Si 3 N 4 Ions are implanted into the GaSb substrate (201) of the protective layer (202)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com