A step-by-step and partitioned preparation method of a NOx adsorption-reduction bifunctional catalyst

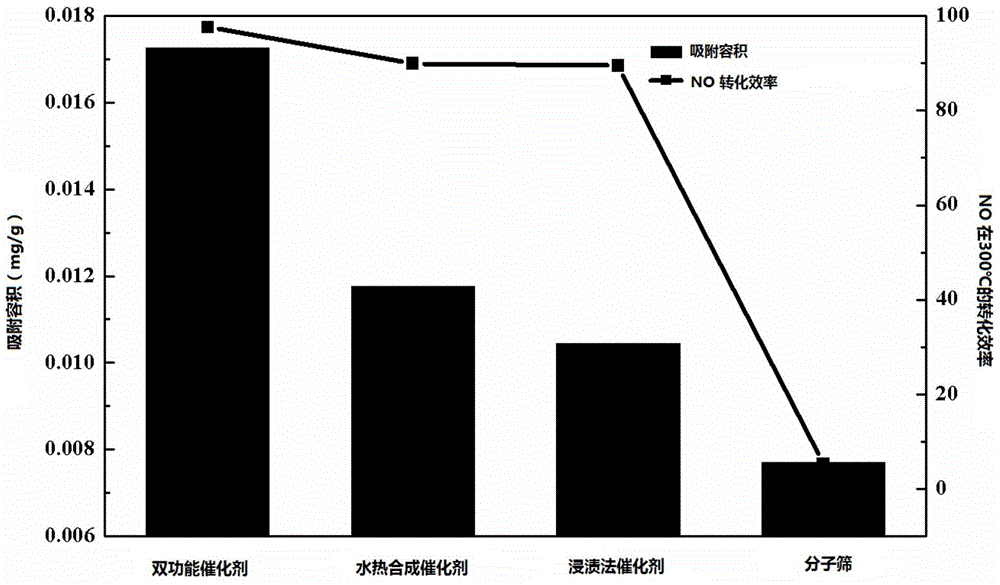

A dual-function catalyst and metal technology, applied in the direction of separation methods, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of unreachable adsorption performance and reduced NOx removal efficiency, etc., to achieve weakened mutual interference, efficient storage and efficient reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The method for preparing NOx adsorption and reduction bifunctional catalyst step by step and partition, specifically includes the following steps:

[0025] (1) Using the porous medium powder ZSM-5 series molecular sieve as the carrier, the inorganic salt BaCl 2 Prepared as an aqueous solution of inorganic salt (5% w.t.), the organic salt Fe(AA) of the reduced metal 3 Prepare organic salt solution (28g / 100ml, solvent benzene);

[0026] (2) Place the carrier in an inorganic salt solution of 2 times the volume of the storage metal, immerse it for 24 hours, then wash it twice with deionized water, and finally place it in an oven at 110°C for 24 hours to obtain a carrier loaded with the storage metal powder;

[0027] (3) Place the carrier powder loaded with stored metal in the organic salt solution of reduced metal twice its volume, soak for 24 hours, then recover the organic solvent by evaporation, and dry the remaining catalyst in an oven at 100°C for 12 hours , and fin...

Embodiment 2

[0029] The method for preparing NOx adsorption and reduction bifunctional catalyst step by step and partition, specifically includes the following steps:

[0030] (1) With porous media powder alumina powder as carrier, the inorganic salt KCl of storage metal is mixed with inorganic salt solution (5%wt), the organic salt nickel oxalate of reduction metal is mixed with organic salt solution (29.4g / 100ml, solvent toluene);

[0031] (2) Place the carrier in an inorganic salt solution of 1.5 times the volume of the storage metal, immerse it for 30 hours, then wash it with deionized water for 3 times, and finally place it in an oven at 120°C for 20 hours to obtain a carrier loaded with the storage metal powder;

[0032] (3) Put the carrier powder loaded with stored metal in the organic salt solution of reduced metal of 1 times its volume, immerse for 20 hours, then recover the organic solvent by evaporation, and dry the remaining catalyst in an oven at 90°C for 20 hours , and fina...

Embodiment 3

[0034] The method for preparing NOx adsorption and reduction bifunctional catalyst step by step and partition, specifically includes the following steps:

[0035] (1) With porous medium powder SSZ-13 series molecular sieve as carrier, the inorganic salt KCl of storage metal is mixed with inorganic salt solution (5%wt), the organic salt nickel oxalate of reduction metal is mixed with organic salt solution (29.4g / 100ml, solvent toluene);

[0036] (2) Place the carrier in 3 times the volume of the inorganic salt solution of the storage metal, soak it for 40 hours, then wash it with deionized water 4 times, and finally place it in an oven at 130°C for 20 hours to obtain a carrier loaded with the storage metal powder;

[0037] (3) Place the carrier powder loaded with stored metal in the organic salt solution of reduced metal 1.5 times its volume, soak for 20 hours, then recover the organic solvent by evaporation, and dry the remaining catalyst in an oven at 90°C for 24 hours , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com