High-conductivity carbon fiber electrode material and preparation method

A carbon fiber electrode, highly conductive technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of non-conductivity and easy dissolution, and achieve the effects of low cost, improved adhesion and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

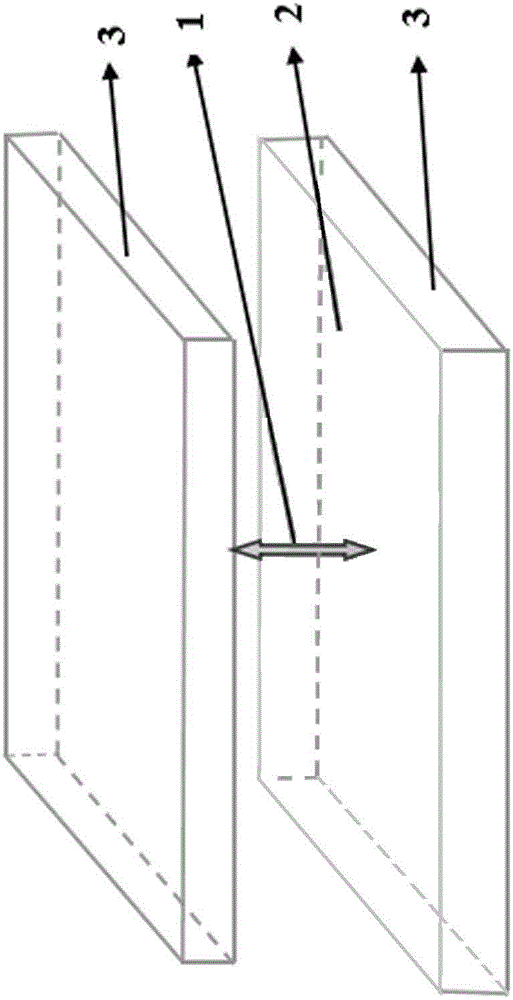

[0032] First cut the carbon fiber cloth to a suitable size, then use a mixture containing 70g sodium hydroxide, 30g sodium carbonate and 10 drops of cleaning agent per liter to degrease the surface of the carbon fiber cloth for 30 minutes at room temperature, and then mix the carbon fiber cloth solution together in an ultrasonic cleaner for ultrasonic treatment for 20 minutes, and then the surface of the carbon fiber cloth was cleaned with distilled water. Boil the carbon fiber cloth, wash it and dry it naturally, stack the multi-layer carbon fiber cloth after drying, and coat the conductive resin glue with a thickness of 0.5mm between each two layers of carbon fiber, and apply the conductive resin glue to the multi-layer carbon fiber. Carry out glue sealing treatment around the cloth and dry it for later use.

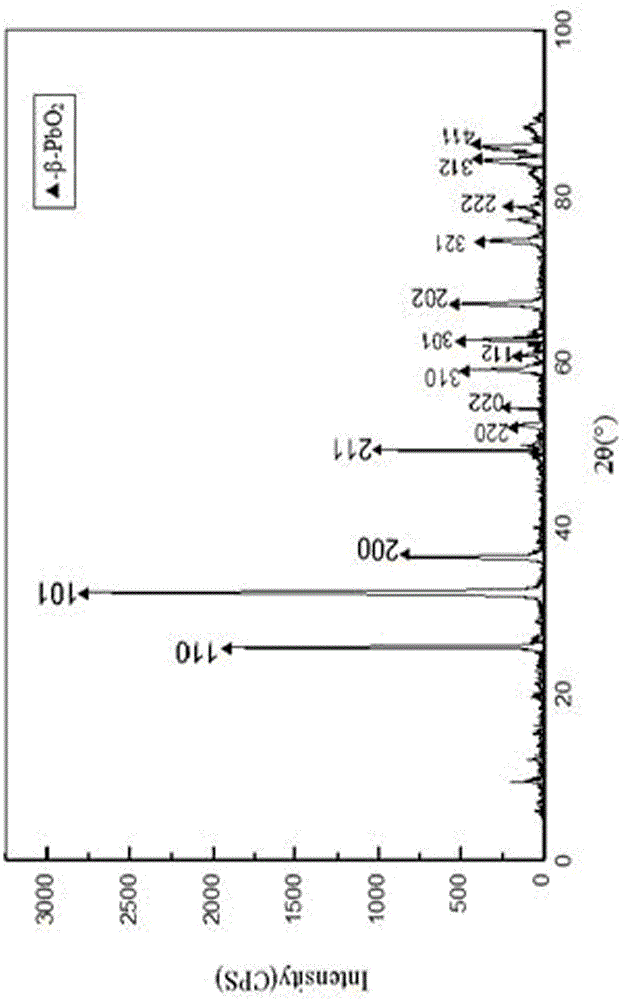

[0033] At a temperature of 65°C, use a mixed solution containing 150g of lead nitrate, 1g of sodium fluoride, and 25mL of concentrated nitric acid per liter with a cur...

Embodiment 2

[0035]First cut the carbon fiber cloth to a suitable size, then degrease the surface of the carbon fiber cloth for 10 minutes at room temperature with a mixed solution containing 100g sodium hydroxide, 5g sodium carbonate and 3 drops of cleaning agent per liter, and then mix the carbon fiber cloth solution together in an ultrasonic cleaner for ultrasonic treatment for 60 minutes, and then the surface of the carbon fiber cloth was cleaned with distilled water, and then the cleaned carbon fiber cloth was immersed in concentrated nitric acid with a mass fraction of 65% at room temperature for 50 minutes for surface etching treatment, and then the surface was etched with distilled water. Boil the carbon fiber cloth, wash it and dry it naturally, stack the multi-layer carbon fiber cloth after drying, and coat the conductive resin glue with a thickness of 0.1mm between each two layers of carbon fiber, and apply the conductive resin glue to the multi-layer carbon fiber. Carry out glue...

Embodiment 3

[0038] First cut the carbon fiber cloth to a suitable size, then use a mixture containing 50g sodium hydroxide, 50g sodium carbonate and 20 drops of cleaning agent per liter to degrease the surface of the carbon fiber cloth for 60 minutes at room temperature, and then mix the carbon fiber cloth liquid together in an ultrasonic cleaner for ultrasonic treatment for 30 minutes, and then the surface of the carbon fiber cloth was cleaned with distilled water. Boil the carbon fiber cloth, wash it, and dry it naturally. Stack the multi-layer carbon fiber cloth after drying, and apply a conductive resin glue with a thickness of 1mm between each two layers of carbon fiber. Seal the surrounding area and let it dry for later use.

[0039] At a temperature of 80°C, use a mixed solution containing 200g of lead nitrate, 3g of sodium fluoride, and 30mL of concentrated nitric acid per liter with a current density of 60mA·cm -2 , Electrodeposition time 2.5h, electrode plate spacing 5cm, elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com