Red fluorescent powder and preparation method thereof

A technology for red phosphor powder and compound, applied in the field of red phosphor powder and its preparation, can solve the problems of low quantum conversion rate, low luminous intensity, low cost, etc., and achieve the effects of high luminous intensity, uniform particle size and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

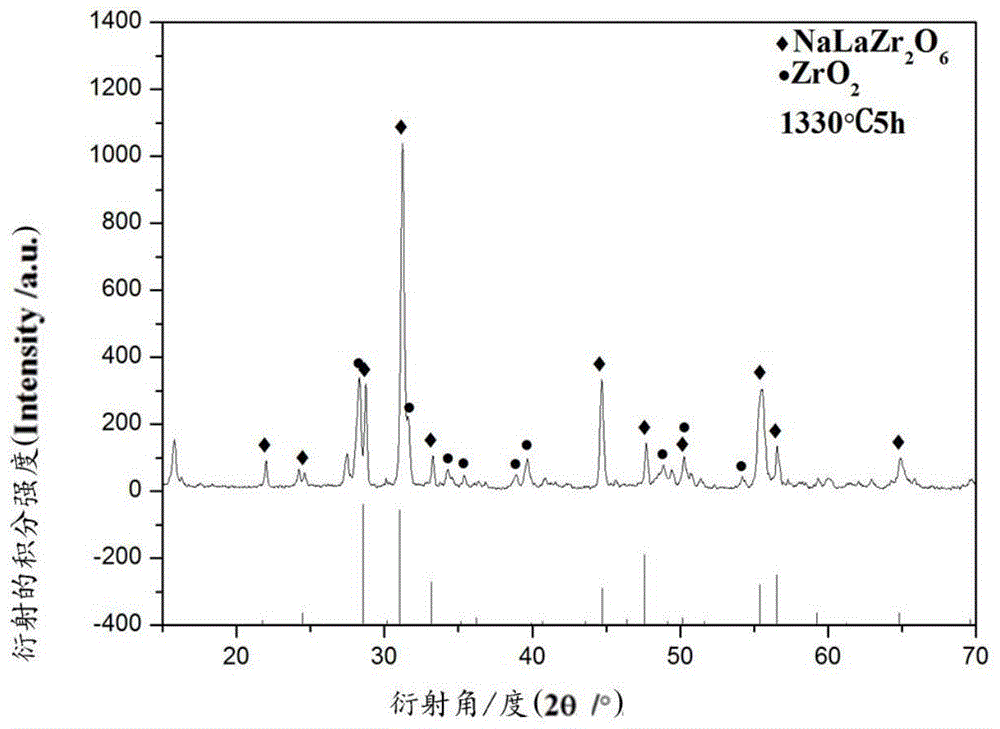

Embodiment 1

[0030] 1) select commercially available purity as analytically pure Na 2 CO 3 , La 2 o 3 , ZrO 2 And the purity is high purity reagent Eu 2 o 3 As a reaction raw material, according to the chemical formula NaLa 0.97 Zr 2 o 6 : 0.03Eu 3+ The stoichiometric ratio is weighed, wherein, considering that the Na source will be partially burned at high temperature, so when weighing Na 2 CO 3 Weigh 1.5 times of its stoichiometric ratio;

[0031] 2) Put the weighed material into a vibrating ball mill for dry grinding and mixing, and control the output particle size at 0.3mm.

[0032] 3) Put the uniformly mixed material into an oven and dry it at 150° C. for 3 hours.

[0033] 4) Put the dried sample into a corundum crucible, place the corundum crucible in a muffle furnace, and raise it from room temperature to 600 °C at a rate of 3 °C / min in an air atmosphere, and then increase it at a rate of 5 °C / min Raise the temperature to 1300°C and keep it warm for 5 hours.

[0034] 5...

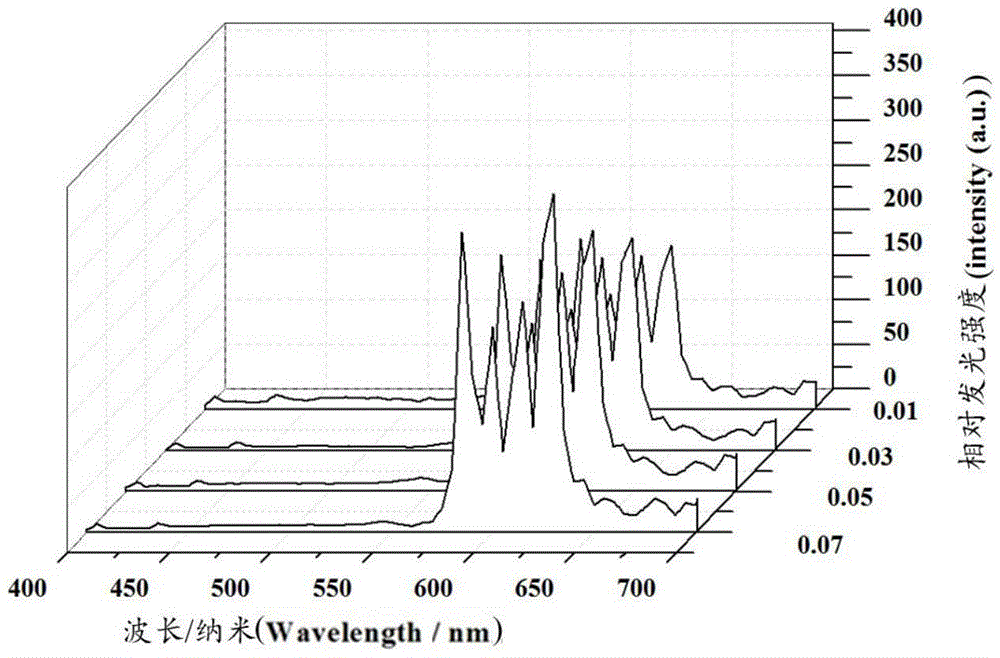

Embodiment 2

[0036] 1) select commercially available purity as analytically pure Na 2 CO 3 , La 2 o 3 , ZrO 2 And the purity is high purity reagent Eu 2 o 3 As a reaction raw material, according to the chemical formula NaLa 0.95 Zr 2 o 6 : 0.05Eu 3+ The stoichiometric ratio is weighed, wherein, considering that the Na source will be partially burned at high temperature, so when weighing Na 2 CO 3 Weigh 1.5 times of its stoichiometric ratio;

[0037]2) Put the weighed raw meal into a vibration ball mill for dry grinding and mixing, and control the output particle size at 0.2mm.

[0038] 3) Put the uniformly mixed material into an oven and dry at 150° C. for 4 hours.

[0039] 4) Put the dried sample into a corundum crucible, place the corundum crucible in a muffle furnace, and raise it from room temperature to 600 °C at a rate of 2 °C / min in an air atmosphere, and then increase it at a rate of 4 °C / min Raise the temperature to 1330°C and keep it warm for 6h.

[0040] 5) Cool do...

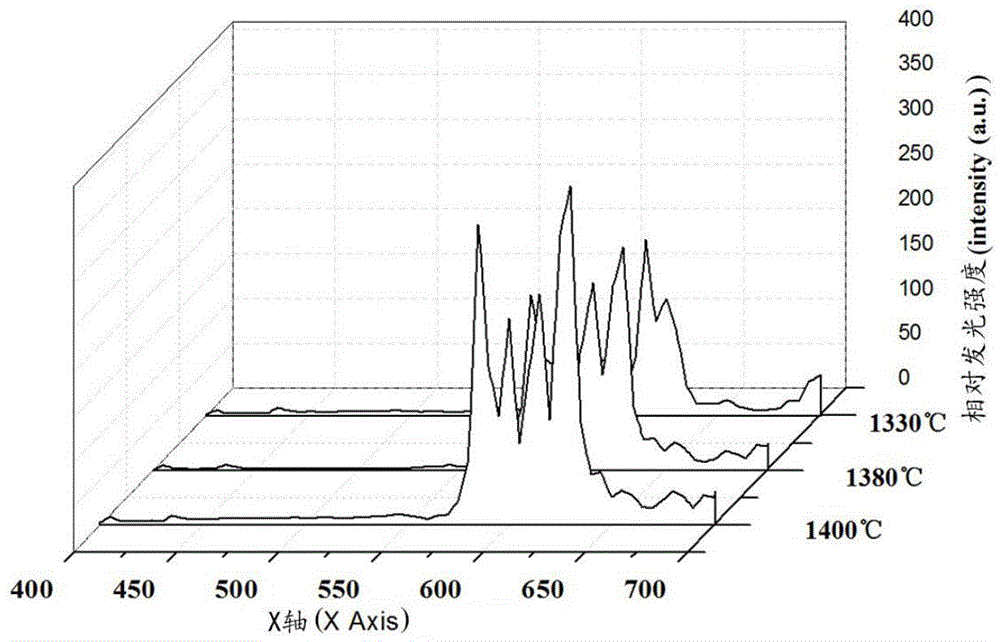

Embodiment 3

[0042] 1) select commercially available purity as analytically pure Na 2 CO 3 , La 2 o 3 , ZrO 2 And the purity is high purity reagent Eu 2 o 3 As a reaction raw material, according to the chemical formula NaLa 0.93 Zr 2 o 6 : 0.07Eu 3+ The stoichiometric ratio is weighed, wherein, considering that the Na source will be partially burned at high temperature, so when weighing Na 2 CO 3 Weigh 1.5 times of its stoichiometric ratio;

[0043] 2) Put the weighed material into a vibrating ball mill for dry grinding and mixing, and control the output particle size at 0.3mm.

[0044] 3) Put the uniformly mixed material into an oven and dry at 180° C. for 4 hours.

[0045] 4) Put the dried sample into a corundum crucible, place the corundum crucible in a muffle furnace, and raise it from room temperature to 600°C at a rate of 3°C / min in an air atmosphere, and then increase it to 600°C at a rate of 3°C / min. The temperature was raised to 1400°C and kept for 5 hours.

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com