Preparation method of hydrogen absorption component

A technology of element and hydrogen absorbing alloy, which is applied in the field of preparing hydrogen absorbing elements for high temperature vacuum heat collector tubes of solar thermal power generation, can solve the problem of affecting the activation temperature and hydrogen absorbing performance of the hydrogen absorbing element, reducing the hydrogen absorbing performance of the hydrogen absorbing element, and limiting the absorption of hydrogen. problems such as the specific surface area of the hydrogen element, to achieve the effects of excellent hydrogen absorption performance, improved hydrogen absorption performance, and a wide range of options

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

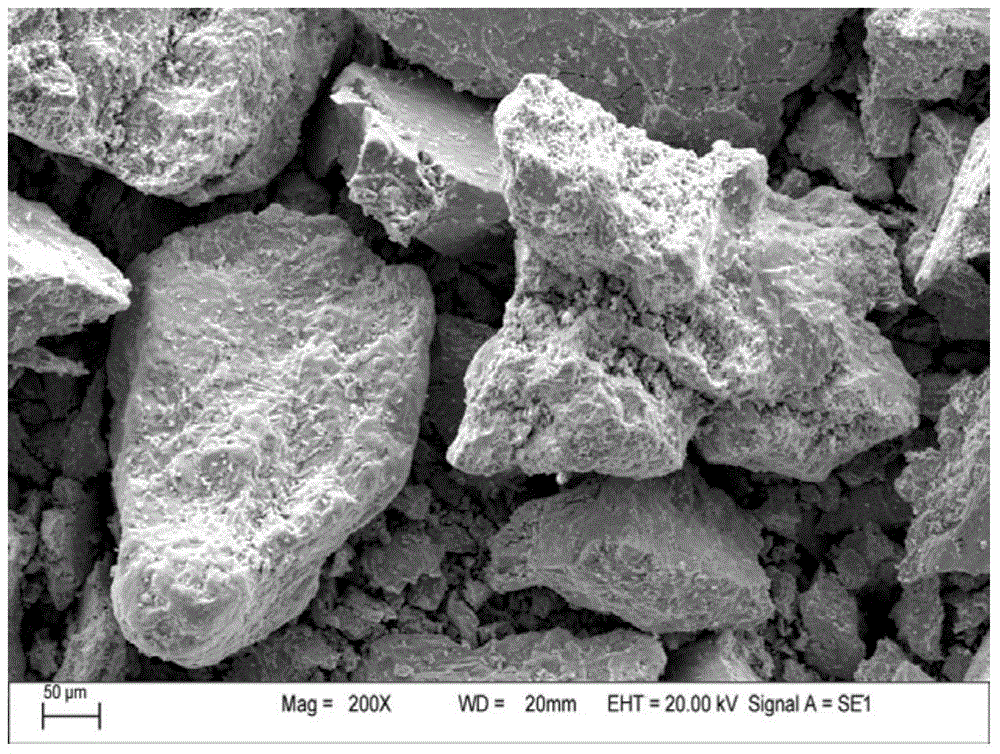

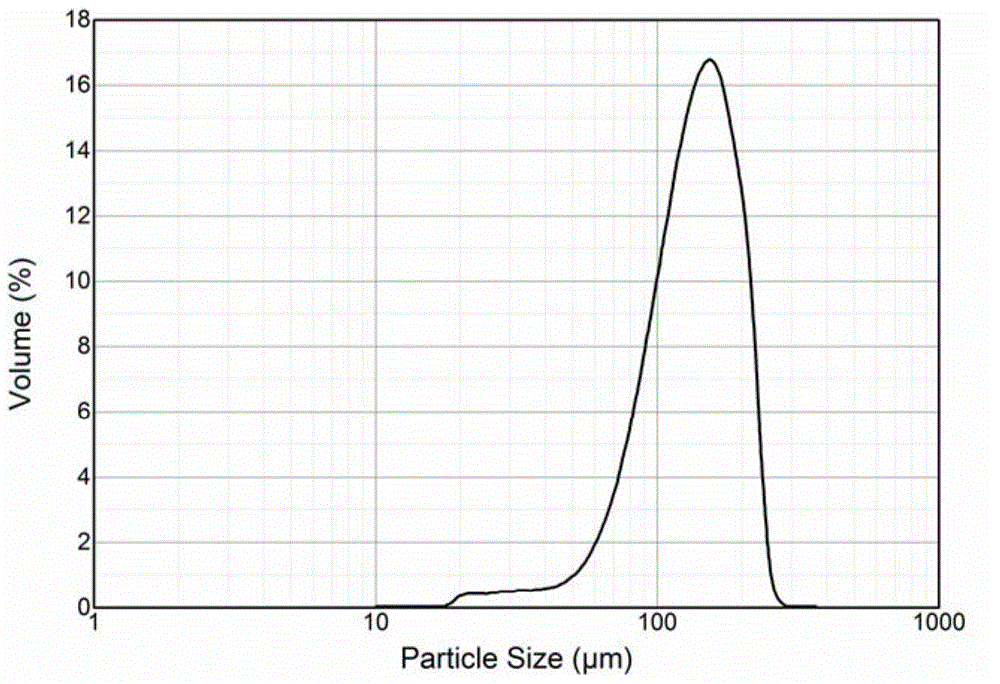

[0042] Adopt the preparation method of the present invention, promptly the cast ingot after smelting is at 500 ℃, 1×10 -2 Vacuumize and heat for 30 minutes under Pa vacuum, cool to room temperature and continue to flow 0.1MPa hydrogen for 60 minutes. The alloy block after hydrogen absorption is crushed to 20 mesh by ball milling, and the powder enters the jet mill. The grinding gas is argon (purity ≥ 99.999%), the pressure is 0.50MPa, and the sorting frequency is 60Hz. The powder produced by the jet mill enters the radio frequency plasma spheroidization equipment, the working gas is argon (purity ≥ 99.999%), and the flow rates of edge gas, working gas and carrier gas are 50L min -1 , 10L·min -1 and 5L·min -1 , the input power is 30kW, and the powder is collected to obtain powder sample 4. The microscopic appearance of the powder is as Figure 6 As shown, the powder is spherical. The particle size distribution of the powder is as Figure 7 As shown, the comprehensive prop...

Embodiment 2

[0056] Adopt the method of the present invention to prepare zirconium, titanium-based solid solution hydrogen-absorbing element, and it is combined with Zr prepared by direct crushing method 57.0 V 35.8 Fe 7.2 (US4312669) Comparison of hydrogen absorption performance of hydrogen absorption components at 390°C.

[0057] The composition of zirconium and titanium based solid solution hydrogen absorbing element is Ti 64.5 Zr 11.3 V 24.2 , the direct crushing method of this alloy cannot realize powder preparation and hydrogen absorbing element forming. The raw materials are Zr (purity ≥99.5%), Ti (purity ≥99.5%), V (purity ≥99.5%), and the melting method is suspension induction melting.

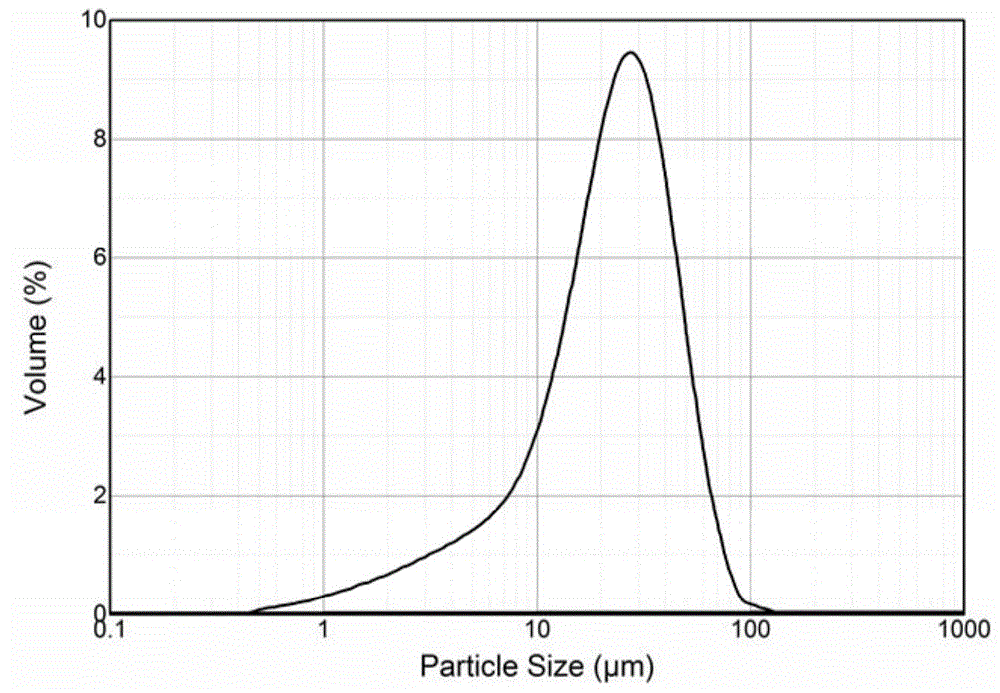

[0058] The smelted ingot is at 400°C, 1×10 -2 Vacuumize and heat for 30 minutes under Pa vacuum, cool to room temperature and continue to flow 0.1MPa hydrogen for 60 minutes. The alloy block after hydrogen absorption is crushed to 20 mesh by ball milling, and the powder enters the jet mill....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com