Al-Cu-Mg-Ti quaternary active solder for high-volume-fraction cast aluminum-based composite material, and preparation method for Al-Cu-Mg-Ti quaternary active solder

An al-cu-mg-ti technology with high volume fraction, applied in welding/cutting media/materials, manufacturing tools, welding equipment, etc., can solve the problems affecting defilming and wetting of demelting elements, and achieve prolonged wetting Wetting reaction time, improvement of wettability and joint performance, effect of improved wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the Al-Cu-Mg-Ti quaternary active solder of the high volume fraction cast aluminum matrix composite material of the present invention comprises the following steps:

[0034] 1) Take a certain amount of Cu block, Al block, Mg block and Al-5Ti alloy, then remove the oil stain and oxide film on the surface of Cu block, Al block, Mg block and Al-5Ti alloy, clean it ultrasonically and dry it, and then Melting, and then naturally cooling to room temperature to obtain ingots, wherein the smelting is carried out under the protection of argon. The specific process of smelting is as follows: first place Cu block, Al block and Al-STi alloy in a crucible to heat and melt, after heat preservation Add Mg block and keep warm;

[0035] 2) Put the ingot obtained in step 1) into the container, fix the container on a rotating water-cooled copper roller, and then heat and melt the ingot in the container under the protection of argon, and pass the melted The ingot...

Embodiment 2

[0040] The preparation method of the Al-Cu-Mg-Ti quaternary active solder of the high volume fraction cast aluminum matrix composite material of the present invention comprises the following steps:

[0041] 1) Take a certain amount of Cu block, Al block, Mg block and Al-5Ti alloy, then remove the oil stain and oxide film on the surface of Cu block, Al block, Mg block and Al-5Ti alloy, clean it ultrasonically and dry it, and then Melting, and then naturally cooling to room temperature to obtain ingots, wherein the smelting is carried out under the protection of argon. The specific process of smelting is: first place Cu block, Al block and Al-5Ti alloy in a crucible to heat and melt, after heat preservation Add Mg block and keep warm;

[0042] 2) Put the ingot obtained in step 1) into the container, fix the container on a rotating water-cooled copper roller, and then heat and melt the ingot in the container under the protection of argon, and pass the melted The ingot is blown o...

Embodiment 3

[0047] The preparation method of the Al-Cu-Mg-Ti quaternary active solder of the high volume fraction cast aluminum matrix composite material of the present invention comprises the following steps:

[0048] 1) Take a certain amount of Cu block, Al block, Mg block and Al-5Ti alloy, then remove the oil stain and oxide film on the surface of Cu block, Al block, Mg block and Al-5Ti alloy, clean it ultrasonically and dry it, and then Melting, and then naturally cooling to room temperature to obtain ingots, wherein the smelting is carried out under the protection of argon. The specific process of smelting is: first place Cu block, Al block and Al-5Ti alloy in a crucible to heat and melt, after heat preservation Add Mg block and keep warm;

[0049] 2) Put the ingot obtained in step 1) into the container, fix the container on a rotating water-cooled copper roller, and then heat and melt the ingot in the container under the protection of argon, and pass the melted The ingot is blown o...

PUM

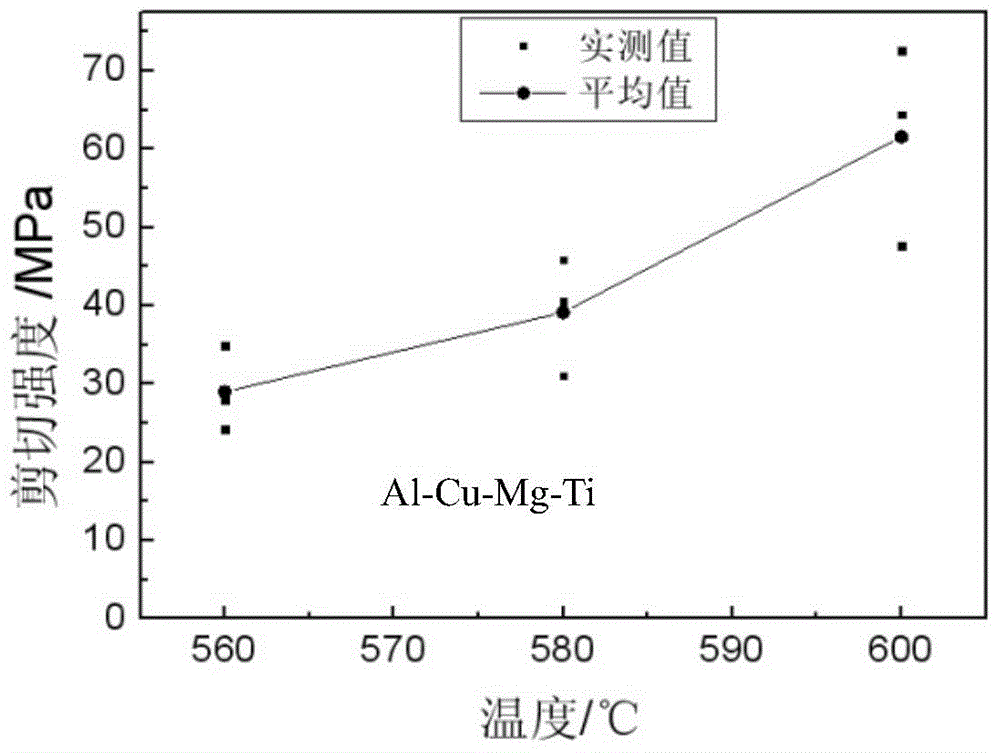

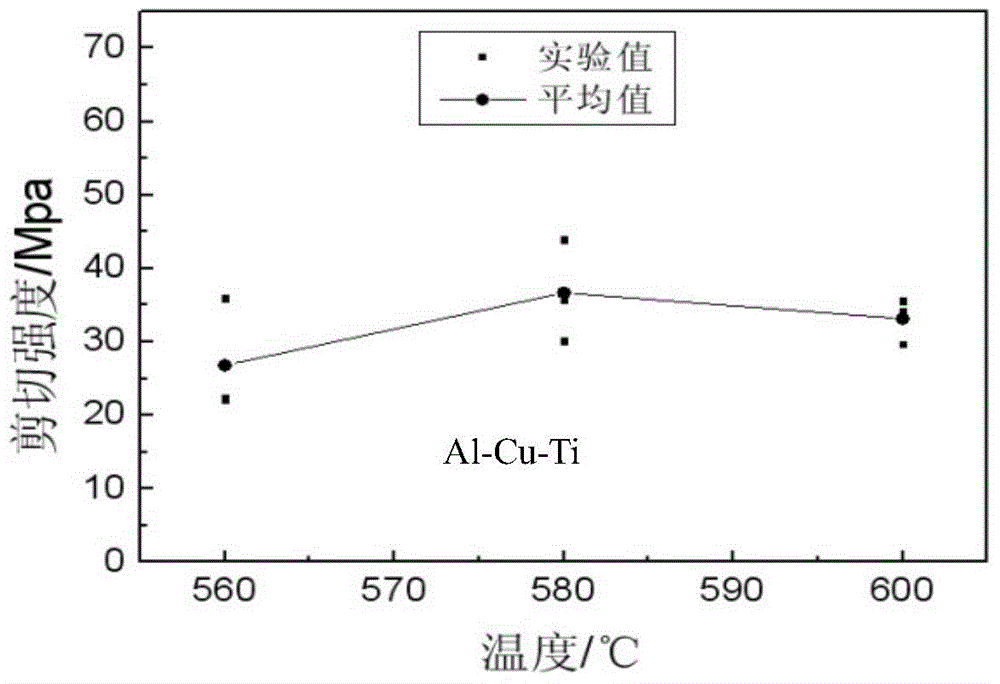

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com