Material for new energy battery cases and preparation method of material

A battery casing and new energy technology, which is applied in the field of special materials for new energy battery casings and its preparation, can solve problems such as poor heat resistance and heat transfer performance, poor low-temperature toughness and thermal conductivity, and long-term use performance effects, etc., to prolong the service life , excellent mechanical properties, and the effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

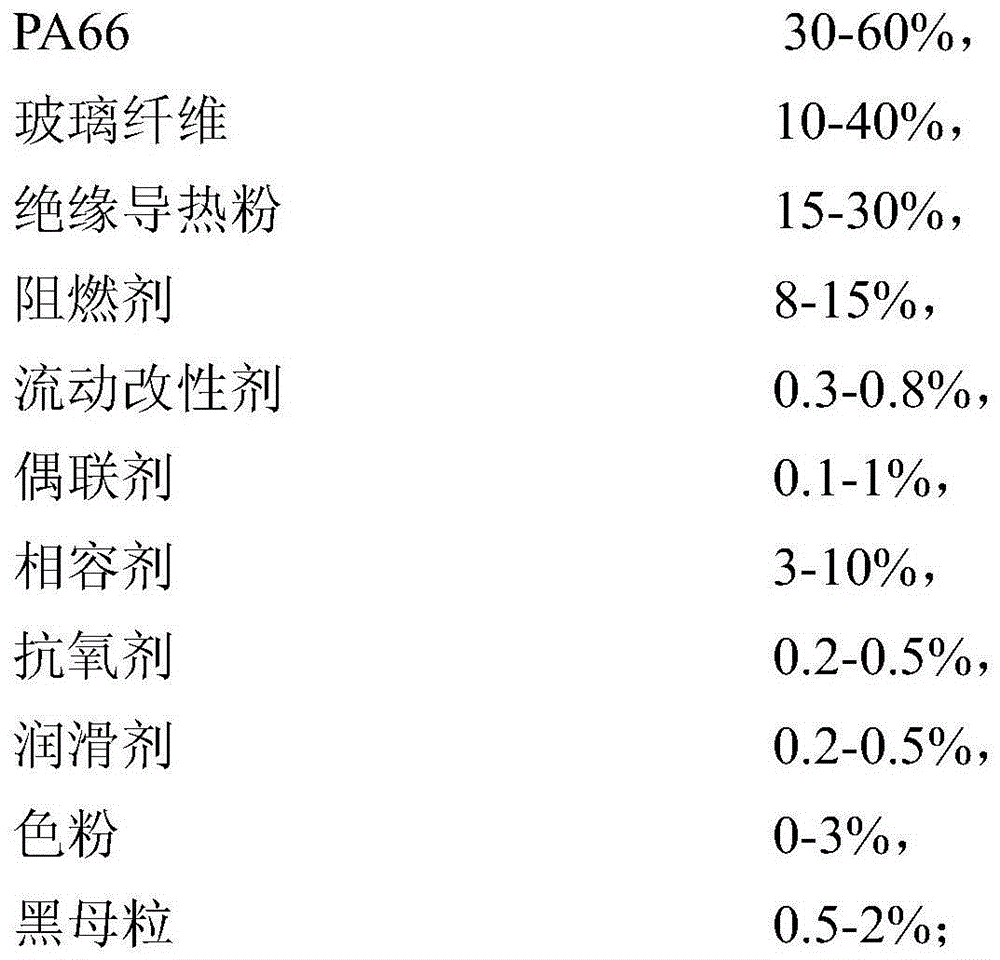

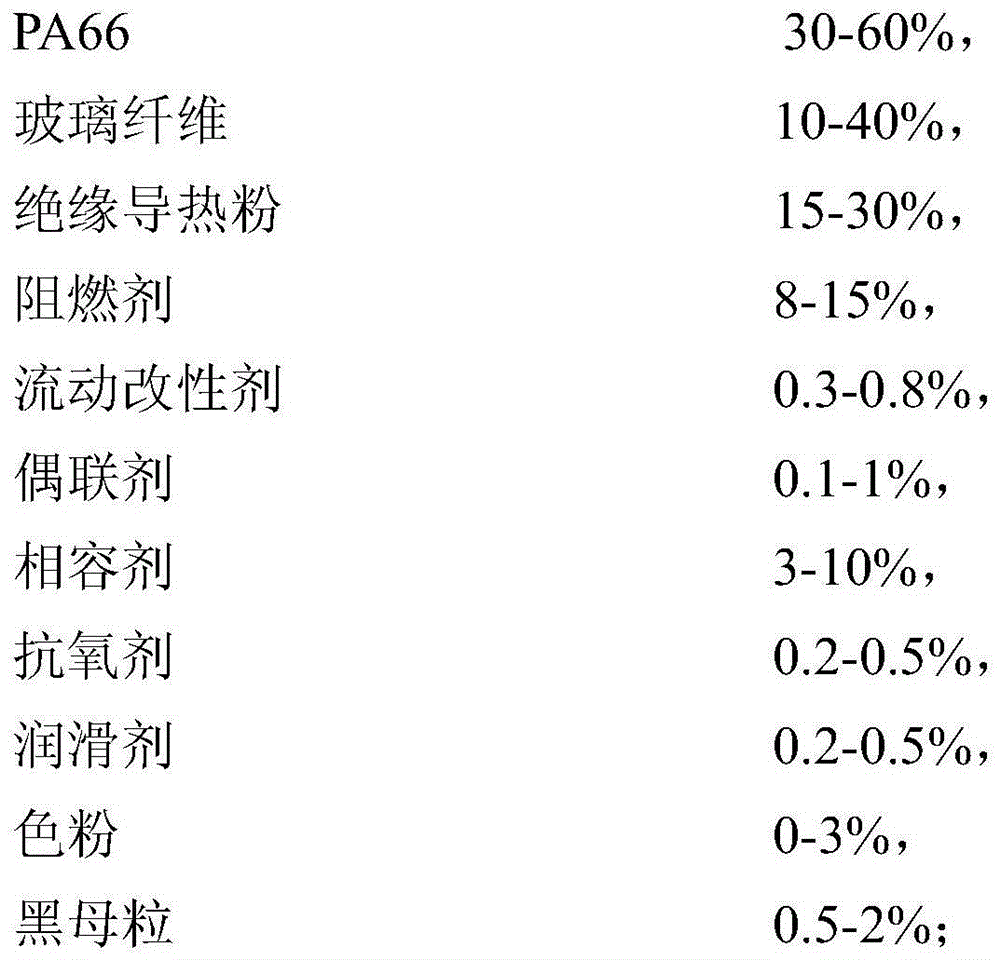

[0032] Embodiment 1 Preparation of material of the present invention (1)

[0033] (1) Take raw materials by weight percentage content: PA66 (viscosity 2.50): 44%, glass fiber 10%, aluminum oxide (50 μ m in particle size) 25%, coated red phosphorus 10%, flow modifier SiO 0.4%, Silane coupling agent 0.2%, compatibilizer POE-MAH 5%, antioxidant 168 / 1098 0.4%, silicone powder 0.5%, green powder 3%, black masterbatch 1.5%;

[0034] (2) Bake the PA66 at 100°C for 8 hours;

[0035] (3) Carry out pretreatment to powdery filler, join above-mentioned aluminum oxide, coated red phosphorus, green powder in the high-speed mixer, then add silane coupling agent, mix evenly, set aside;

[0036] (4) Add the above-mentioned uniformly mixed powder filler together with PA66, glass fiber, flow modifier, compatibilizer, antioxidant, silicone powder and black masterbatch into a high-speed mixer and mix evenly, and then add it to the double In the main feeding barrel of the screw extruder;

[0037...

Embodiment 2

[0038] Embodiment 2 Preparation of material of the present invention (two)

[0039] (1) Weigh raw materials by weight percentage: PA66 (viscosity 3.40): 39.5%, glass fiber 20%, silicon carbide (particle size 5 μm) 5%, boron nitride (particle size 50 μm) 15%, coated red phosphorus 8%, flow modifier SiO 0.3%, silane coupling agent 1%, compatibilizer EPDM-MAH 10%, antioxidant 168 / 1098 0.5%, silicone powder 0.2%, black masterbatch 0.5%;

[0040] (2) Bake the PA66 at 90°C for 10 hours;

[0041] (3) Pretreat the powdery filler, add the above-mentioned silicon carbide, boron nitride, and coated red phosphorus into a high-speed mixer, then add a silane coupling agent, mix evenly, and set aside;

[0042] (4) Add the above-mentioned uniformly mixed powder filler together with PA66, glass fiber, flow modifier, compatibilizer, antioxidant, silicone powder and black masterbatch into a high-speed mixer and mix evenly, and then add it to the double In the main feeding barrel of the screw e...

Embodiment 3

[0044] Embodiment 3 Preparation of material of the present invention (three)

[0045] (1) Weigh raw materials by weight percentage: PA66 (viscosity 2.10): 60%, glass fiber 10%, magnesium oxide (particle size 50 μm) 15%, coated red phosphorus 8%, flow modifier long-chain multifunctional group Ester 0.8%, isopropyl tris(dioctyl pyrophosphate acyloxy) titanate 0.1%, compatibilizer EVA-MAH 3%, antioxidant 168 / 1098 0.2%, EBS 0.4%, green powder 2% , black masterbatch 0.5%;

[0046] (2) Bake the PA66 at 110°C for 5 hours;

[0047] (3) Pretreat the powdery filler, add the above-mentioned magnesium oxide, coated red phosphorus, and green powder into the high-speed mixer, and then add isopropyl tris (dioctyl pyrophosphate acyloxy) titanate, Mix well and set aside;

[0048] (4) Add the above-mentioned uniformly mixed powder filler together with PA66, glass fiber, flow modifier, compatibilizer, antioxidant, EBS and black masterbatch into a high-speed mixer and mix evenly, and then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com