Preparation method of graphite-TiO2-B composite material

A composite material, -tio2-b technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of application limitation, easy to agglomerate, poor TiO2 conductivity, etc., and achieve low cost, good rate performance and cycle. Stability, the effect of improving chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A graphene-TiO 2 -The preparation method of composite material, this method comprises the following steps:

[0027] (1) Preparation of graphene

[0028] Using graphite powder as raw material, using the Hummers method, namely NaNO 3 Add it into concentrated sulfuric acid, add graphite powder and potassium permanganate after complete dissolution, further react to obtain a bright yellow system, obtain graphite oxide after filtration and drying, and then pass through a tube furnace to prepare graphene through thermal expansion.

[0029] (2) Bud-shaped TiO 2 - Preparation of B

[0030] 4mlTiCl 3 , 4ml of deionized water and 40ml of ethylene glycol were put into a beaker and stirred for 10min. The mixture was transferred to a 50ml autoclave, reacted at 150°C for 6h, and cooled naturally to room temperature. Centrifuge and wash with ethanol and deionized water several times. Then dry at 60°C for 8h, put the dried powder in a muffle furnace for sintering at 400°C for 2h,...

Embodiment 2

[0034] (1) The preparation method of graphene is the same as step (1) in Example 1.

[0035] (2) Bud-shaped TiO 2 - Preparation of B

[0036] 4mlTiCl 3 , 4ml of deionized water was stirred at room temperature, 120ml of ethylene glycol was added, stirred for 10min, the mixture was transferred to a 150ml autoclave, reacted at 150°C for 4h, and naturally cooled to room temperature. After centrifugation, wash with ethanol and deionized water several times. Dry at 60°C for 8h, place the dried powder in a muffle furnace for sintering at 300°C for 4h, and cool naturally to obtain flower-like TiO 2 -B material.

[0037] (3) Graphene and TiO 2 The preparation of -B composite material is the same as step (3) in Example 1.

Embodiment 3

[0039] (1) The preparation method of graphene is the same as step (1) in Example 1.

[0040] (2) Bud-shaped TiO 2 - Preparation of B

[0041] 1.0mlTiCl 4 Dissolve in 80ml of ethylene glycol, stir at room temperature for 2h, then add 2mL of ammonia water (25wt%), and stir for 10min. The mixture was transferred to a 100ml autoclave, reacted at 150°C for 24h, and cooled naturally to room temperature. After centrifugation, wash with ethanol and deionized water several times. Dry at 100°C for 8h, place the dried powder in a muffle furnace for sintering at 350°C for 2h, and cool naturally to obtain flower-like TiO 2 -B material.

[0042] (3) Graphene and TiO 2 The preparation of -B composite material is the same as step (3) in Example 1.

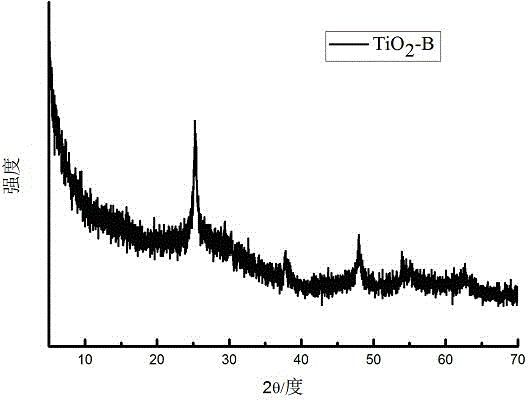

[0043] Depend on figure 1 As shown, the bud-shaped TiO 2 It can be seen from the XRD spectrum of -B that the products are all TiO 2 -B (Bronzemine) structure; by figure 2 Bud-shaped TiO 2 From the scanning electron microscope image of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com