Method for preparing titanium oxide based ceramic membrane layer on surface of light metal or alloy of light metal

A manufacturing method and technology of ceramic film layer, which is applied in the direction of anodic oxidation, electrolytic inorganic material coating, etc., can solve the problems of large transition layer size, poor bonding force, and high porosity of titanium alloy micro-arc oxidation coating, so as to improve production efficiency , Improve efficiency, excellent hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

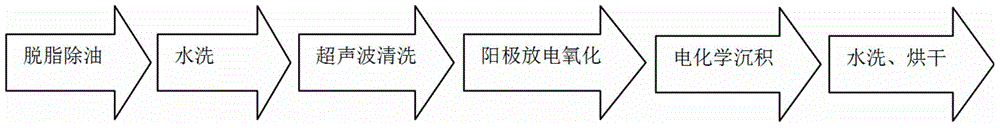

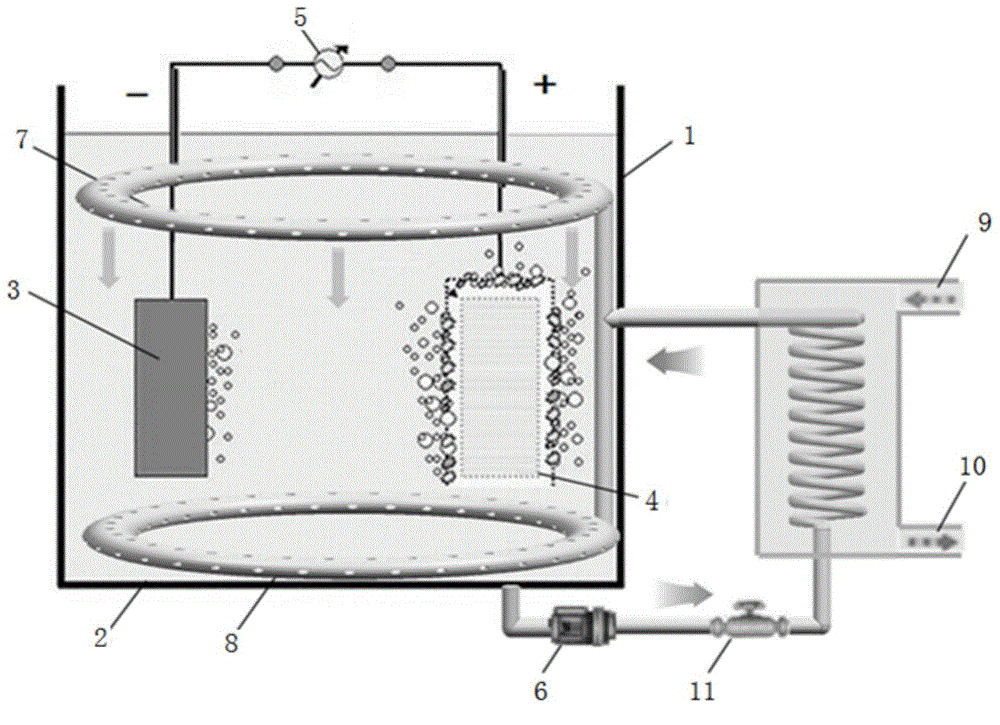

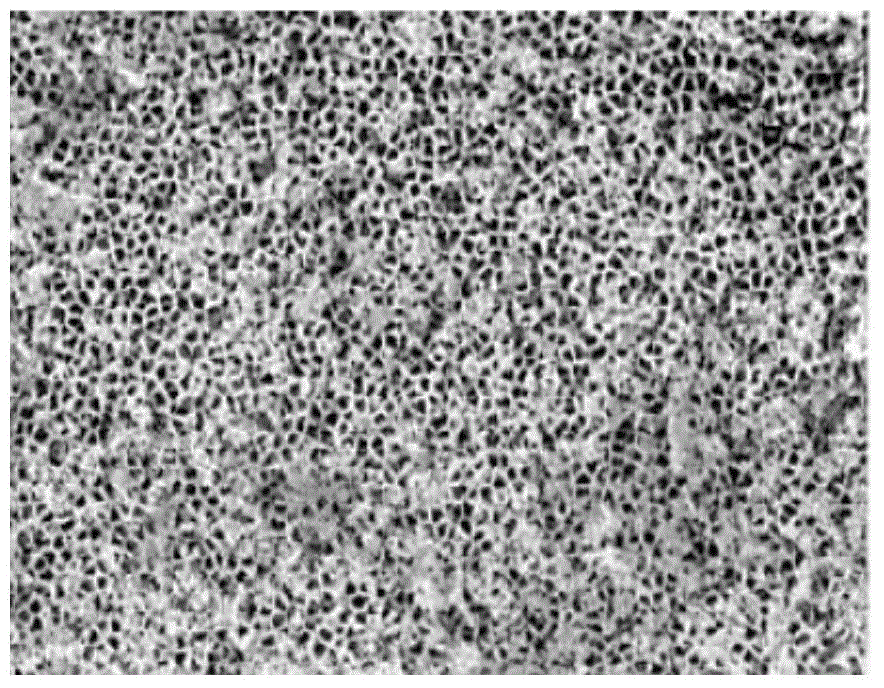

[0035] refer to figure 1 and figure 2 , according to an embodiment of the present invention, a method for manufacturing a titanium oxide-based ceramic film layer on the surface of a light metal or its alloy, using a composite process of anodic plasma discharge oxidation and electrochemical deposition, comprising: light metal or its alloy (such as aluminum or magnesium or titanium substrate) or workpieces covered with light metals or their alloys, first in an acidic solution containing titanium salts with a pH value of 1.5 to 5.0, at 3 to 10A / dm 2 , Anode plasma discharge oxidation under DC voltage of 10-50V, to obtain a layer of dense, uniform, porous oxide film, the film layer is mainly composed of a lar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com