Preparation method of unenhanced halogen-free flame retardant nylon 66

A technology of flame retardant nylon and flame retardant, applied in the field of preparation of non-reinforced halogen-free flame retardant nylon 66, which can solve the problems of high flame retardant grade, large addition amount, poor flame retardant effect, etc., and achieve excellent flame retardancy , high flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of non-enhanced halogen-free flame-retardant nylon 66 proposed by the present invention comprises the following steps:

[0018] (1) Synthetic halogen-free flame retardant:

[0019] Disperse acid chloride compounds and amines in toluene at a molar ratio of (1-3):1, stir at room temperature and heat to 90°C-110°C, reflux for 4-8 hours, and filter the reflux product Afterwards, dry in a stepwise heating manner, wash the product twice, filter, and dry the filtered product at 150°C for 3-5 hours to obtain a white halogen-free flame retardant, wherein the acyl chloride compound is benzoyl chloride, Any one of oxalyl chloride, acetyl chloride, terephthaloyl chloride, phthaloyl chloride, isophthaloyl chloride or trimesoyl chloride, and the amines mentioned are melamine, melamine cyanurate, melamine Any one of phosphate, melamine oxalate, melamine hydrochloride, aniline, p-phenylenediamine, ethylenediamine, hexamethylenediamine, 4,4'-diaminodiphenyl ether...

Embodiment 1

[0030] (1) Benzoyl chloride and melamine are dispersed in toluene at a molar ratio of 3:1, heated to 108°C after stirring at room temperature, and refluxed for 6 hours. Dry at 120°C for 1 hour, heat up to 150°C for 2 hours, heat up to 180°C for 2 hours, dry at 200°C for 2 hours, wash the product twice with water, filter and dry at 150°C for 5 hours to obtain white halogen-free Flame retardant 1, the yield is 90%.

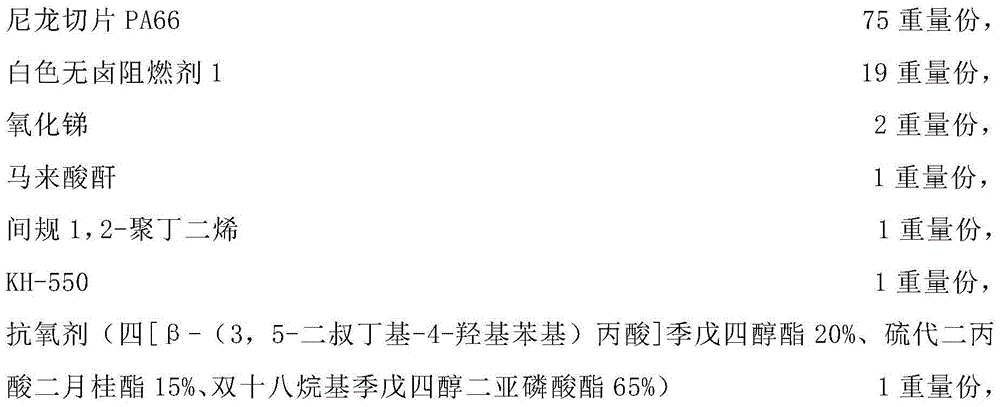

[0031] (2) Set the temperature of the nylon slices at 105°C for constant temperature drying for 5 hours, and prepare the raw materials according to the following ratio:

[0032]

[0033] Add the above-mentioned raw materials to the high-speed mixer after weighing the above-mentioned parts by weight and mix evenly;

[0034] (3) Preheat the twin-screw extruder, and set the temperatures of the conveying section, melting section, extrusion section, exhaust section and shear section to 260°C, 275°C, 275°C, 270°C and 265°C respectively , keep warm for 30 minutes afte...

Embodiment 2

[0036] (1) Oxalyl chloride and melamine oxalate were dispersed in toluene at a molar ratio of 1.5:1, heated to 98°C after stirring at room temperature, and refluxed for 5 hours. After filtering the refluxed reaction product, it was dried in a stepwise heating manner. That is, the temperature was raised to 120°C for 1 hour, the temperature was raised to 150°C for 2 hours, the temperature was raised to 180°C for 2 hours, and the temperature was raised to 200°C for 2 hours. Halogen-free flame retardant 2, the yield is 92%.

[0037] (2) Set the temperature of the nylon slices at 105°C for constant temperature drying for 5 hours, and prepare the raw materials according to the following ratio:

[0038]

[0039] Add the above-mentioned raw materials to the high-speed mixer after weighing the above-mentioned parts by weight and mix evenly;

[0040](3) Preheat the twin-screw extruder, and set the temperatures of the conveying section, melting section, extrusion section, exhaust sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com