Fire-retardant and heat-resistant PPO (poly-p-phenylene oxide) alloy and preparation method thereof

An alloy and heat-resistant technology, which is applied in the field of flame-retardant and heat-resistant PPO alloys and their preparation, can solve the problems of high flame retardancy, high toughness requirements, and unmet requirements, and achieve improved flame retardancy, good fluidity, and improved warping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

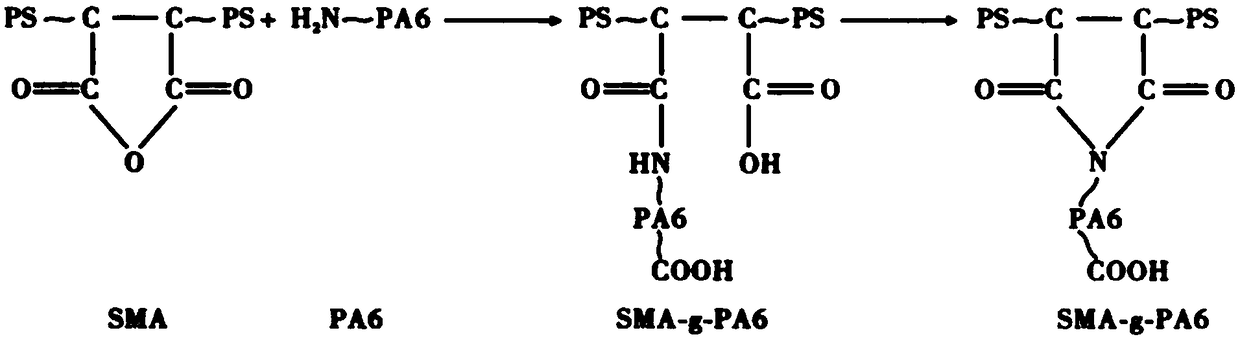

Method used

Image

Examples

Embodiment 1

[0056] This embodiment provides a flame-retardant and heat-resistant PPO alloy, in parts by weight, the formula is as follows:

[0057] PPO resin

85

PA6 resin

15

Compound powder

5

flame retardant

10

Compatibilizer

10

0.4

[0058] PPO, number average molecular weight is 25000, PA6, number average molecular weight is 40000.

[0059] In the composite powder, the mass ratio of barium sulfate, talcum powder, and glass fiber powder is 1:1:5, and the weight of KH550 accounts for 0.3% of the total weight of the composite powder. The compound powder mixing process is as follows: first put the glass fiber powder and talc powder into the low-speed mixer in proportion, add KH550, mix at a speed of 100r / min for 3min, and then add barium sulfate and mix at a speed of 100r / min for 5min. The flame retardant is resorcinol bis(diphenyl phosphate), melamine cyanurate, and triphenylphosphine mixed in a mass ratio of 1...

Embodiment 2

[0064] This embodiment provides a flame-retardant and heat-resistant PPO alloy, in parts by weight, the formula is as follows:

[0065] PPO resin

80

PA6 resin

20

Compound powder

10

flame retardant

11

Compatibilizer

11

0.5

[0066] PPO, number average molecular weight is 37500, PA6, number average molecular weight is 55000.

[0067] In the composite powder, the mass ratio of barium sulfate, talcum powder, and glass fiber powder is 1:1:5, and the weight of KH550 accounts for 0.3% of the total weight of the composite powder. The compound powder mixing process is as follows: first put the glass fiber powder and talc powder into the low-speed mixer in proportion, add KH550, mix at a speed of 150r / min for 3 minutes, and then add barium sulfate and mix at a speed of 150r / min for 5 minutes. The flame retardant is resorcinol bis(diphenyl phosphate), melamine cyanurate, and triphenylphosphine mixed in a mass...

Embodiment 3

[0072] This embodiment provides a flame-retardant and heat-resistant PPO alloy, in parts by weight, the formula is as follows:

[0073] PPO resin

75

PA6 resin

25

Compound powder

15

flame retardant

12

Compatibilizer

12

antioxidant

0.6

[0074] PPO, number average molecular weight is 50000, PA6, number average molecular weight is 70000.

[0075] The compound powder is medium, the mass ratio of barium sulfate, talc powder, and glass fiber powder is 1:1:5, and the weight of KH550 accounts for 0.3% of the total weight of the compound powder. The compound powder mixing process is as follows: first put the glass fiber powder and talc powder into the low-speed mixer in proportion, add KH550, mix at a speed of 200r / min for 3min, and then add barium sulfate and mix at a speed of 200r / min for 5min. The flame retardant is resorcinol bis(diphenyl phosphate), melamine cyanurate, and triphenylphosphine mixed in a mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com