Sorafenib lipidosome freeze-dried injection for injection and preparation method thereof

A technology of sorafenib grease and freeze-dried powder injection, which is applied in the field of medicine, can solve the problems of low solubility of sorafenib, difficulty in avoiding the first-pass effect, aggravating toxic and side effects, etc., so as to reduce the adverse reactions of patients and avoid the first-pass effect, the effect of reducing the economic burden of patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 30mg lecithin, 40mg dimyristyl phosphatidylglycerol, 15mg cholesterol, 15mg PEG-DSPE2000, and 3mg sorafenib were dissolved in chloroform, and the solution was evenly rotated in a round bottom flask on a 25-30oC constant temperature water bath and reduced The organic solvent was evaporated under pressure to allow the lipid to form a uniform film on the bottom inner wall of the flask, which was then placed under vacuum at room temperature for an additional 2 hours. After fully drying, add 2ml of 10mM sodium carbonate, 100mM sodium chloride, and 10mM HEPES buffer (pH 9), and wash the membrane evenly on a 35°C constant temperature water bath until the membrane is hydrated to a milky white liposome suspension. The diameter is about 100nm. 400 mg of sucrose was dissolved in liposomes, filtered through a membrane filter with a pore size of 0.2 μm, added with a lyoprotectant, and freeze-dried.

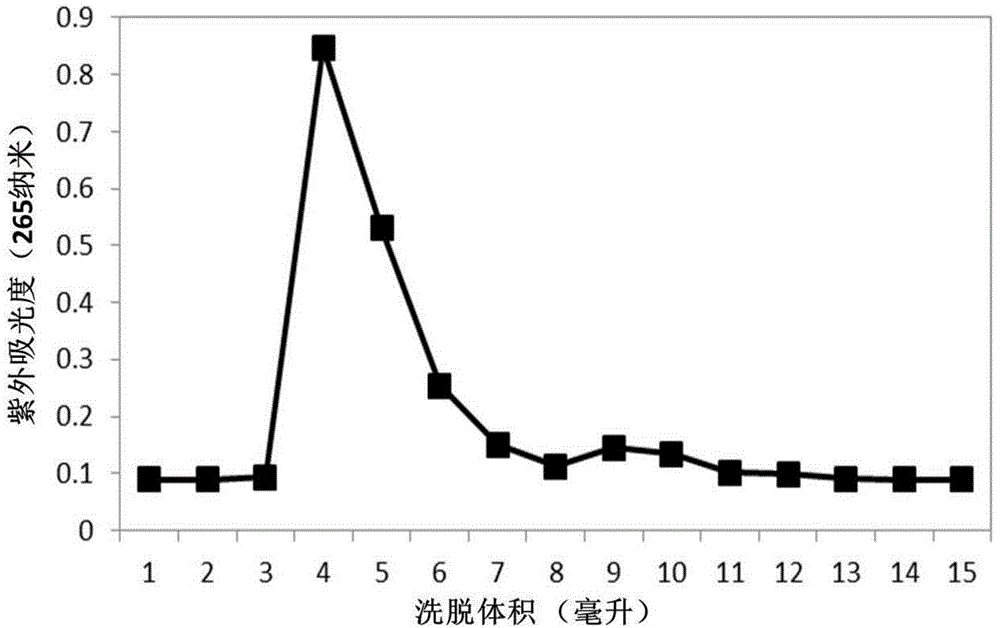

[0041] After the lyophilized Sorafenib liposome lyophilized powder was stored at r...

Embodiment 2

[0043] Dissolve 400mg soybean lecithin (purity>94% phosphatidylcholine), 600mg dimyristyl phosphatidylglycerol, 200mg cholesterol, 20mg PEG-DSPE2000, 40mg sorafenib in ether. Then add 20ml of isotonic phosphate solution with pH 8 into the above ether solution for emulsification, then remove the organic solvent under reduced pressure, and reduce the particle diameter to about 100nm by ultrasonic probe. Then 2.5 g of sucrose was dissolved in the above solution, filtered through a membrane filter with a pore size of 0.2 μm aseptically, a lyoprotectant was added, the final dispersion was divided into vials, and freeze-dried.

[0044] After the freeze-dried Sorafenib liposome freeze-dried powder was stored at room temperature for 3 months, the liposome encapsulation rate obtained after adding water for injection reconstitution was 90%, and the particle size was 155nm.

Embodiment 3

[0046]100 mg of synthetic phospholipids (purity>94% phosphatidylcholine), 150 mg of dipalmitoylphosphatidylglycerol, 50 mg of cholesterol, and 55 mg of polyethylene glycol PEG-DSPE2000 were dissolved in ether. Add 4ml of isotonic phosphate solution of pH 8.5 into the above-mentioned ether solution for emulsification, then remove the organic solvent under reduced pressure, and reduce the diameter of the particle to about 100nm by ultrasonic probe to complete the preparation of the blank liposome. In addition, 10 mg of sorafenib was dissolved in 4 ml of isotonic phosphate solution of pH 8.5, then fully mixed with blank liposomes, adjusted to pH 7.0 with 200 mM HCl, and then equilibrated in a constant temperature water bath at 37°C for 30-60 min. After equilibration, dissolve 400 mg of sucrose in the above solution, filter it through a membrane filter with a pore size of 0.2 μm, add a lyoprotectant, divide the final dispersion into vials, and freeze-dry.

[0047] After the freeze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com