Device reducing light degradation of solar cell and method thereof

A solar cell and light-induced attenuation technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low output, high power consumption, and insufficient effect, and achieve low cost, low power consumption, and obvious effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

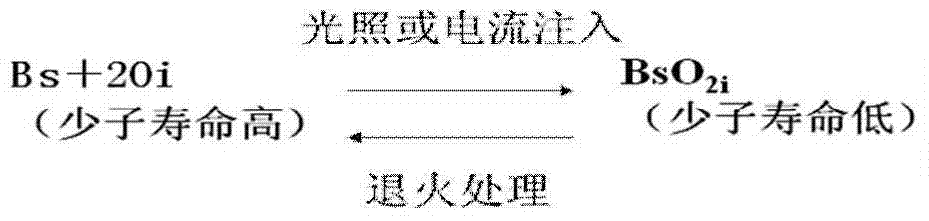

Problems solved by technology

Method used

Image

Examples

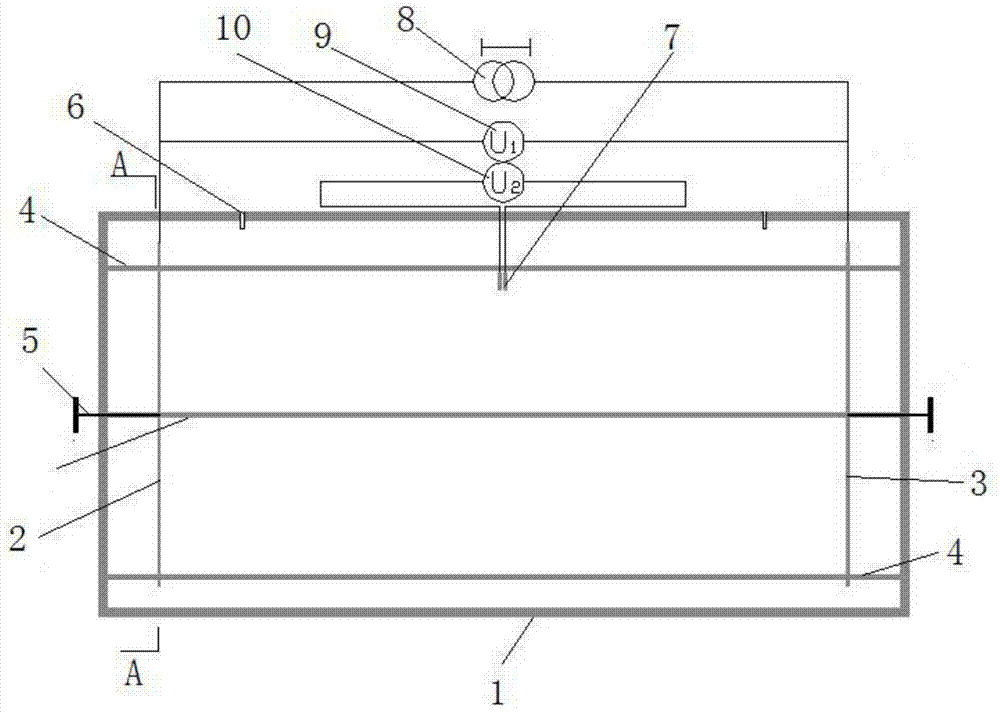

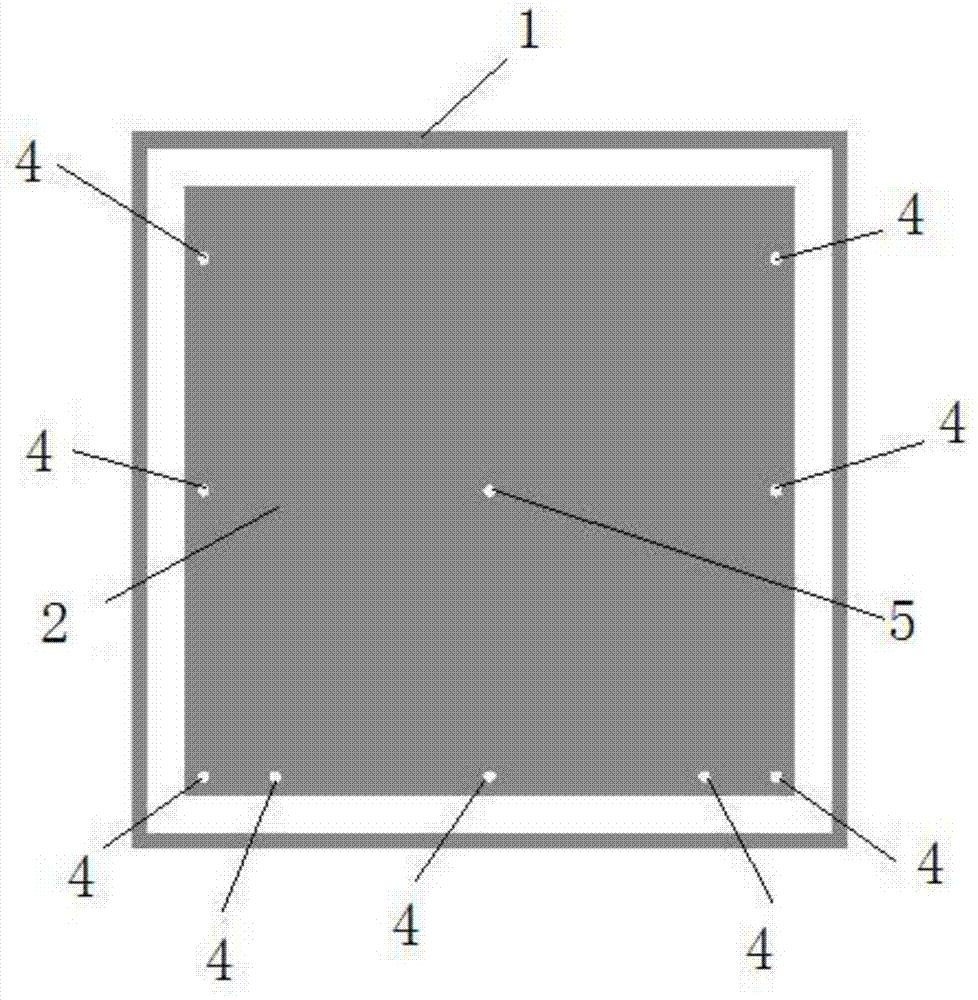

Embodiment 1

[0041] Implementation Example 1: 100 sheets of monocrystalline solar cells with a conversion efficiency of 19.0% and a side length of 156 mm (the cell area is 238.95 cm 2 ), put it in the constant temperature box, fix the left conductive plate and the right conductive plate, connect the circuit, and cover the upper cover of the constant temperature box; Start access to N 2 ; After the preheating is completed, turn on the power supply and pass a positive DC current to the cell, with a current density of 3mA / cm 2 , and at the same time set the temperature of the incubator at 125°C for treatment, keep the N 2 ;Observe the changes of the first voltmeter and the second voltmeter, record the change value of the second voltmeter with time, until the second voltmeter is stable; wait for the battery slice to cool down, take out the battery slice to test its electrical performance, and compare the electric current before treatment. Performance and efficiency: package the processed sol...

Embodiment 2

[0042] Implementation example 2: according to the method described in implementation example 1, 100 sheets of monocrystalline solar cells with a conversion efficiency of 19.2% and a side length of 156mm (the cell area is 238.95cm 2 ) were processed in the same way, and the treated solar cells were packaged in modules, and a group of untreated solar cells with the same conversion efficiency gear were also selected for module packaging. As a control, the two modules were exposed to sunlight Downlight 60KWh / m 2 , to test the light-induced attenuation of the components; comparative analysis, the treated solar cells, the light attenuation of the component power is within 1%, while the power attenuation of the control component reaches 3.5%.

Embodiment 3

[0043] Implementation example 3: Considering the influence of the current factor passed in during the processing of the cell on the processing result, on the basis of implementation example 1, change the current density passed in to 2mA / cm 2 and 20mA / cm 2 Divide into two groups, and other conditions remain unchanged. Each group selects 100 monocrystalline cells with a conversion efficiency of 19.0% and a side length of 156 mm for the experiment. During the battery processing process, the first and second voltmeters are analyzed. Changes; also test the electrical performance and efficiency of the battery after processing, and package the components, 60KWh / m 2 Sunlight, and compare the results of light attenuation. It is basically consistent with the result in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com