Back field aluminum paste applied to n-type crystalline silicon solar cells and preparation method thereof

A technology of solar cells and back-field aluminum paste, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems such as no patent reports, and achieve simple preparation process and adhesion Strong, reduce the effect of light-induced attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

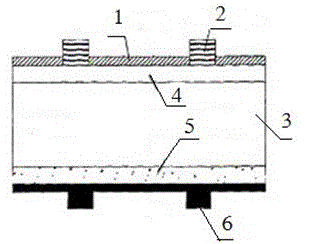

Image

Examples

Embodiment 1

[0022] A back field aluminum paste applied to N-type crystalline silicon solar cells, which consists of the following components in parts by weight: 65 parts of nitrogen atomized aluminum powder, 15 parts of organic binder, 0.5 parts of glass powder, and 0.5 parts of additives parts, the composition and weight percentage of the organic binder are 20% high molecular polymer and 80% organic solvent. The composition and weight ratio of the organic solvent: terpineol: butyl carbitol: lecithin = 3:2:1. Auxiliaries include high-doping additives and corrosion-resistant additives. Among them, the high-doping additive is a silicon-aluminum-boron ternary alloy, and the silicon-aluminum-boron ternary alloy is composed of the following components in parts by weight: 0.5 parts of silicon, 75 parts of aluminum and 10 parts of boron.

[0023] A preparation method for a back field aluminum paste applied to an N-type crystalline silicon solar cell, comprising the following steps:

[0024] (1...

Embodiment 2

[0028] A back field aluminum paste applied to N-type crystalline silicon solar cells, which consists of the following components in parts by weight: 85 parts of nitrogen atomized aluminum powder, 30 parts of organic binder, 3 parts of glass powder, and 3 parts of additives parts, the composition and weight percentage of the organic binder are 40% high molecular polymer and 80% organic solvent.

[0029] The high molecular polymer is one or more of polyvinyl acetal resin, polyamide resin and ethyl cellulose; the composition and weight ratio of the organic solvent: terpineol: butyl carbitol: egg Phospholipids=3:2:1. Auxiliaries include high-doping additives and corrosion-resistant additives. The high-doping additive is a silicon-aluminum-boron ternary alloy, and the silicon-aluminum-boron ternary alloy is composed of the following components by weight: 3 parts of silicon, 85 parts of aluminum and 20 parts of boron.

[0030] A preparation method for a back field aluminum paste a...

Embodiment 3

[0035] A back field aluminum paste applied to N-type crystalline silicon solar cells, which consists of the following components in parts by weight: 80 parts of nitrogen atomized aluminum powder, 20 parts of organic binder, 2 parts of glass powder, and 2 parts of additives parts, the composition and weight percentage of the organic binder are 30% polymer and 70% organic solvent. The high molecular polymer is one or more of polyvinyl acetal resin, polyamide resin and ethyl cellulose; the composition and weight ratio of the organic solvent: terpineol: butyl carbitol: lecithin=3 :2:1, additives include high-doping additives and corrosion-resistant additives, high-doping additives are silicon-aluminum-boron ternary alloys, and silicon-aluminum-boron ternary alloys are composed of the following components in parts by weight: 1 part of silicon, 80 parts aluminum and 15 parts boron.

[0036] A preparation method for a back field aluminum paste applied to an N-type crystalline silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com