Low-cost light mullite-based heat preservation material and preparation method thereof

A mullite-based, thermal insulation technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of high cost, high process conditions, high sintering temperature, achieve strong mechanical strength, simple preparation process, reduce Effect of sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

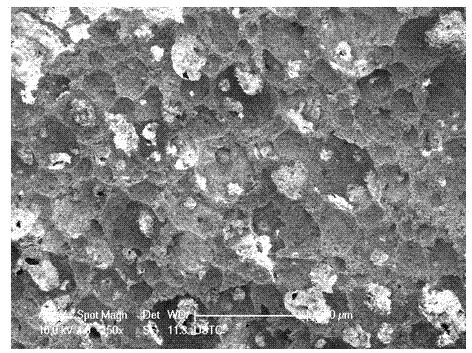

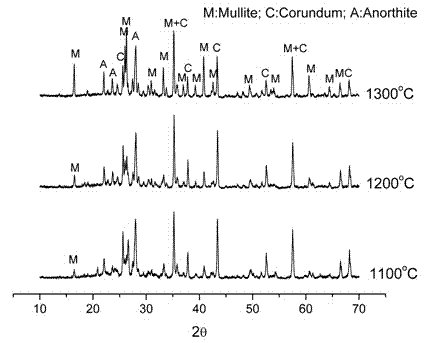

Image

Examples

Embodiment 1

[0033] (1) Add 20g of fly ash and 30g of bauxite into water and stir, add 0.15g of foam stabilizer CMC and 0.25g of dispersant TAC, and ball mill for 24 hours to obtain primary slurry.

[0034] (2) Heat the primary slurry to 40°C in a water bath and mix it evenly with the gelatin solution (formed by dissolving gelatin in water at 40°C in advance) to obtain 143g of ceramic slurry with a gelatin content of 4wt% and a solid phase content of 35wt%;

[0035] (3) Add 0.43g foaming agent K12, and mechanically stir the slurry for 3 minutes at a rotating speed of 800 rpm to generate a large amount of foam and obtain a foam slurry;

[0036] (4) Pour the foam slurry into the mold, and solidify the gel at room temperature for 24 hours to obtain a wet billet;

[0037] (5) After the moisture on the surface of the wet billet is evaporated to dryness, the mold is demoulded, and it is naturally air-dried at room temperature for 2 days to obtain a green billet;

[0038] (6) Sinter the green bo...

Embodiment 2

[0043] (1) Add 20g of fly ash and 30g of bauxite into water and stir, add 0.25g of foam stabilizer CMC and 0.3g of dispersant TAC, and ball mill them for 24 hours to obtain primary slurry;

[0044](2) Heat the primary slurry to 40°C in a water bath and mix it evenly with the gelatin solution (formed by dissolving gelatin in water at 40°C in advance) to obtain 100g of a stable ceramic slurry with a gelatin content of 4wt% and a solid content of 50wt%. ;

[0045] (3) Add 0.3g foaming agent K12, and mechanically stir the slurry for 3 minutes at a rotational speed of 800 rpm to generate a large amount of foam and obtain a foam slurry;

[0046] (4) Pour the foam slurry into the mold, and solidify the gel at room temperature for 24 hours to obtain a wet billet;

[0047] (5) After the moisture on the surface of the wet billet is evaporated to dryness, the mold is demoulded, and it is air-dried at room temperature for 2 days to obtain a green billet;

[0048] (6) Sinter the green bo...

Embodiment 3

[0051] (1) Add 25g of fly ash and 25g of bauxite into water and stir, add 0.15g of foam stabilizer CMC, 0.25g of dispersant TAC and 2.5g of glass powder, and obtain primary slurry after ball milling for 20 hours;

[0052] (2) Heat the primary slurry to 45°C in a water bath and mix it evenly with the gelatin solution (formed by dissolving gelatin in water at 40°C in advance) to obtain 150g of a stable ceramic slurry with a gelatin content of 4wt% and a solid content of 35wt%. ;

[0053] (3) Add 0.45 g of foaming agent K12, and mechanically stir the slurry for 3 minutes at a rotational speed of 800 rpm to generate a large amount of foam to obtain a foam slurry;

[0054] (4) Pour the foam slurry into the mold, and solidify the gel at room temperature for 20 hours to obtain a wet billet;

[0055] (5) After the moisture on the surface of the wet billet is evaporated to dryness, the mold is demoulded, and it is air-dried at room temperature for 2 days to obtain a green billet;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com