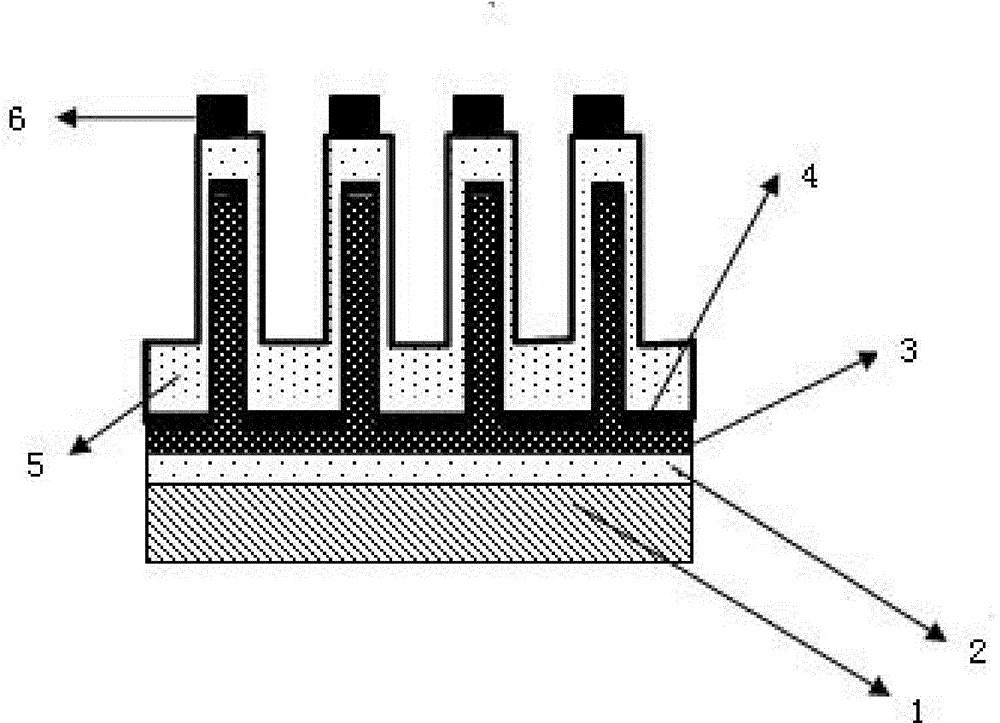

CZTS nanometer array thin film solar photovoltaic cell and manufacturing method thereof

A technology of thin-film solar energy and photovoltaic cells, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of nanowire impurities, limit the large-scale preparation of nanowire arrays, and low production costs, and achieve uniform distribution and convenient large-area application , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of the CZTS nano-array thin-film solar photovoltaic cell of the present embodiment comprises the following steps:

[0043] (1) Polish the copper sheet with No. 0-6 sandpaper, and ultrasonically clean it with alcohol, acetone, and deionized water for 5 minutes; then deposit a layer of Mo on the copper sheet by magnetron sputtering, and the thickness of the Mo layer is 50 μm; A layer of zinc film with a thickness of 1 μm is sputtered on the copper sheet deposited with the Mo layer;

[0044] (2) The product of step (1) is mixed with hydrogen sulfide / oxygen mixed gas, wherein the volume percentage of hydrogen sulfide is 1%, and heated at 50°C for 16h to convert the zinc film into a zinc sulfide nanowire array; The final product is used as the working electrode, the platinum wire is used as the counter electrode, the saturated calomel electrode is used as the reference electrode, the acidic solution containing copper chloride is used as the electrolyte...

Embodiment 2

[0050] The preparation method of the CZTS nano-array thin-film solar photovoltaic cell of the present embodiment comprises the following steps:

[0051] (1) The silicon wafer is ultrasonically cleaned with 1mol / L NaOH, 1mol / L HCl solution, absolute ethanol, and deionized water in sequence; then a layer of Au is magnetron sputtered on the silicon wafer, and the thickness of the Au layer is 800nm ; A zinc film with a thickness of 1 μm was sputtered on a silicon wafer deposited with an Au layer;

[0052] (2) The product of step (1) is mixed with hydrogen sulfide / oxygen mixed gas, wherein the volume percentage of hydrogen sulfide is 30%, and heated at 60°C for 500h to convert the zinc film into a zinc sulfide nanowire array; The final product is used as the working electrode, the platinum wire is used as the counter electrode, the saturated calomel electrode is used as the reference electrode, the acidic solution containing copper chloride, tin chloride and selenous acid is used a...

Embodiment 3

[0058] The preparation method of the CZTS nano-array thin-film solar photovoltaic cell of the present embodiment comprises the following steps:

[0059] (1) Electron beam evaporates one deck ITO on the newly cut mica sheet, and the thickness of the ITO layer is 800nm; Evaporate a layer of thickness on the mica sheet after the electron beam evaporates ITO and be the zinc film of 1 μm;

[0060] (2) The product of step (1) is mixed with hydrogen sulfide / oxygen mixed gas, wherein the volume percentage of hydrogen sulfide is 50%, and heated at 60° C. for 12 hours to convert the zinc film into a zinc sulfide nanowire array; The final product is used as the working electrode, the platinum wire is used as the counter electrode, the saturated calomel electrode is used as the reference electrode, the acidic solution containing copper chloride, tin chloride and selenous acid is used as the electrolyte, and sunlight is placed on the outside of the electrolytic cell. The simulator was used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com