Lithium ion battery insulating coating, preparation method and pole piece and lithium ion battery using insulating coating

A technology for lithium-ion batteries and insulating coatings, applied in the field of lithium-ion battery insulating coatings, pole pieces and lithium-ion batteries, can solve the problems of uneven insulation performance of coatings, affecting lithium-ion batteries, and difficulty in uniform coating. Achieve the effects of easy operation, improved resistance consistency, and uniform stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The lithium-ion battery insulating coating of this embodiment is composed of the following active ingredients in weight percent: 95% of aluminum oxide, 4% of ethylene-vinyl acetate copolymer emulsion, and 1% of sodium methylcellulose.

[0044] The preparation method of the lithium-ion battery insulating coating in this example is as follows: weigh each component according to the composition of the insulating coating, weigh 10 g of sodium methylcellulose and dissolve it in 400 g of water to obtain solution A. Weigh 3500g of deionized water, add 950g of alumina powder into the water and mix evenly to obtain dispersion B, then add 80g of ethylene-vinyl acetate copolymer emulsion to dispersion B, mix evenly, grind and disperse through 0.4mm zirconium beads 5h to get the mixed solution C, then add the solution A to the mixed solution C, mix evenly, stir and disperse at 7000rpm for 2h, and then get the water-based insulating coating.

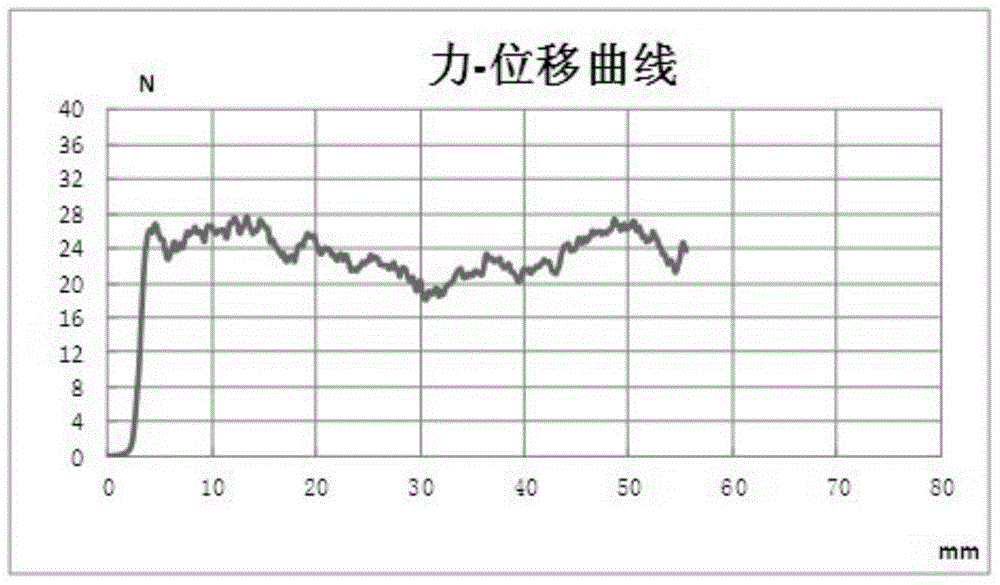

[0045] The insulating coating prepared b...

Embodiment 2

[0049] The lithium-ion battery insulating coating of this embodiment is composed of the following active ingredients in weight percent: 40% of aluminum oxide, 30% of barium sulfate, 29% of styrene-butadiene rubber emulsion, and 1% of polyvinyl alcohol.

[0050] The preparation method of the lithium-ion battery insulating coating in this example is as follows: weigh each component according to the composition of the insulating coating, weigh 10 g of polyvinyl alcohol and dissolve it in 500 g of water to obtain solution A. Weigh 3600g of deionized water, add 400g of alumina powder and 300g of barium sulfate into the water and mix evenly to obtain dispersion B, then add 290g of styrene-butadiene rubber to the dispersion B, mix evenly, grind and disperse through 0.8mm zirconium beads 2h to get the mixed solution C, then add the solution A to the mixed solution C, mix evenly, stir and disperse at 8000rpm for 1h, and then get the water-based insulating coating.

[0051] The insulati...

Embodiment 3

[0054] The lithium-ion battery insulating coating of this embodiment is made up of the active ingredient of following percentage by weight: styrene-butadiene rubber emulsion 30%, ethylene-vinyl acetate copolymer emulsion 45%, polytetrafluoroethylene emulsion 22%, polyoxyethylene 2% , Sodium methylcellulose 1%.

[0055] The preparation method of the lithium-ion battery insulating coating in this example is as follows: weigh each component according to the composition of the insulating coating, weigh 20 g of polyethylene oxide and 10 g of sodium methylcellulose and dissolve them in 600 g of water to obtain solution A. Take by weighing 2000g deionized water, add 600g styrene-butadiene rubber emulsion in water and mix homogeneously, obtain mixed solution B, then add 900g ethylene-vinyl acetate copolymer emulsion in mixed solution B, mix homogeneously, obtain mixed solution C, add to Add 440g of polytetrafluoroethylene emulsion to the mixed solution C, and mix evenly to obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com