Polygonal superhard abrasive compound and method for manufacturing abrasive tool with same

A composite abrasive and polygonal technology, applied in the direction of abrasives, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of affecting the grinding quality, uneven distribution of abrasive grain edges, and insufficient abrasive sharpness, etc., to achieve improved grinding Excellent cutting quality, good toughness, and improved grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

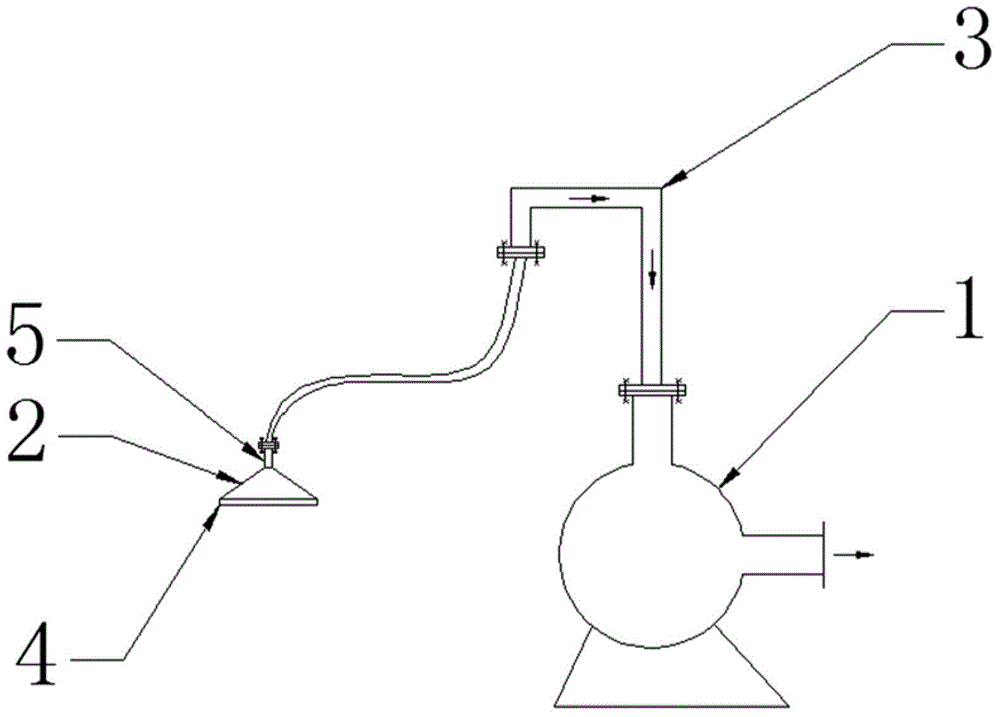

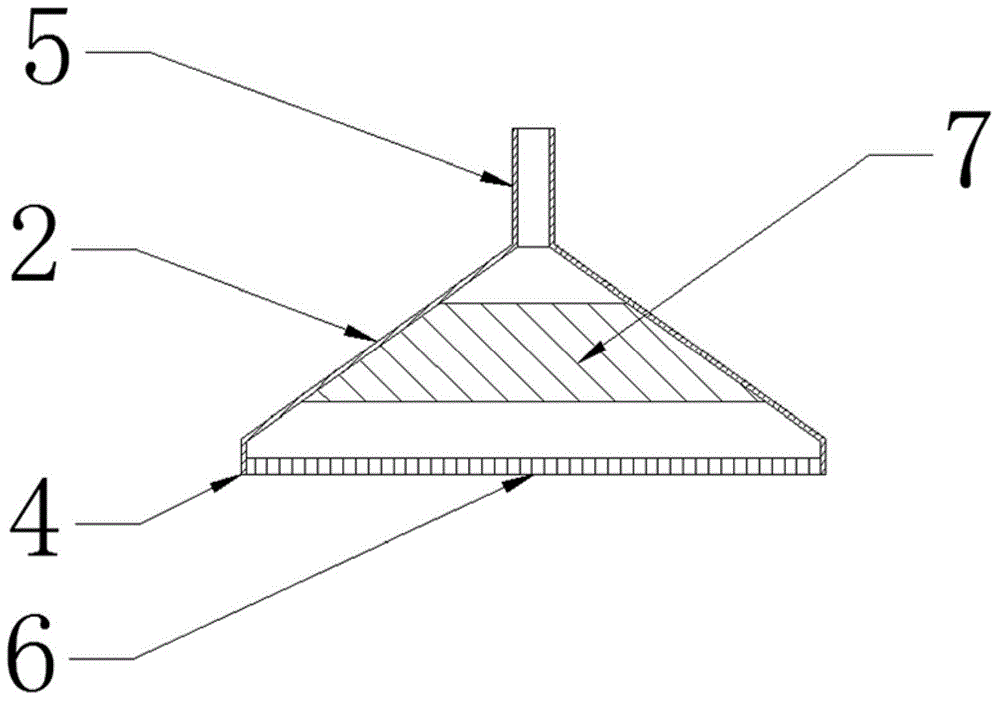

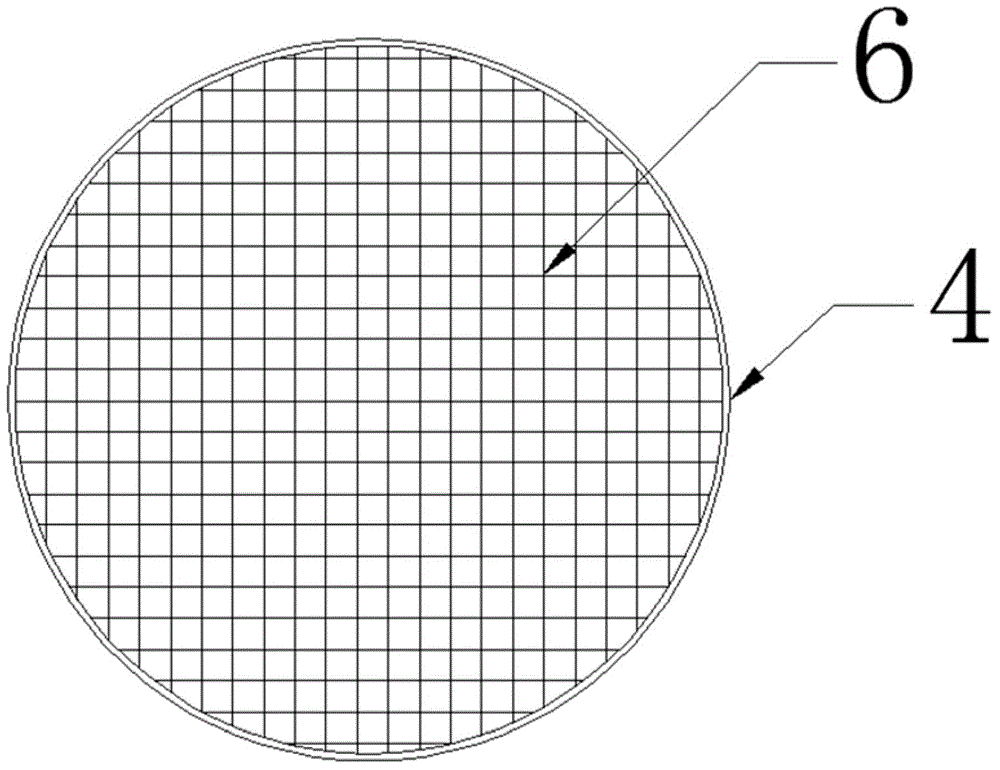

[0052] The abrasive arrangement device of the present embodiment, such as figure 1 , 2 Shown in and 3, comprise vacuum pump 1 and the suction cup 2 of funnel shape, the small opening 5 of described suction cup 2 communicates with vacuum pump 1 through pipeline 3, the large opening end 4 of suction cup 2 is covered with porous thin layer 6, described The porous thin layer 6 is a wire mesh; the funnel-shaped sucker 2 is filled with a transition layer 7 with a porous structure, and the transition layer 7 is used to allow gas to pass through and prevent abrasives from being sucked into the vacuum pump 1; the transition layer is a sponge.

[0053] The physical figure of the abrasive arrangement device of the present embodiment is as follows: Figure 4 , 5 shown. The funnel-shaped suction cup is like a shower structure, and the porous thin layer at the large opening end has regularly arranged small holes. When in use, use the suction force generated by the vacuum pump to suck th...

Embodiment 2

[0056] The polygonal superhard composite abrasive in this example is filled with abrasive powder into the polygonal groove of the graphite mold, assembled into a composite block, placed in a six-sided roof, and synthesized under the conditions of 50,000 atmospheres and 1500°C for 10 minutes The prepared triangular abrasive.

[0057] Wherein, the abrasive powder includes the following components by mass percentage: 30% of cubic boron nitride with a particle size of 0.5-1 μm, 50% of corundum with a particle size of 10-30 μm, and 10% of aluminum nitride with a particle size of 10-30 μm. %, 10% of aluminum powder with a particle size of 1-2 μm. After the above components are uniformly mixed, the abrasive powder is obtained.

[0058] The graphite mold used is as Figure 6 As shown, its polygonal groove is triangular shape. The polygonal groove of described graphite mold adopts engraving machine (Zhengzhou Kechuang numerical control KC-6090 engraving machine, precision reaches 0....

Embodiment 3

[0064] The polygonal superhard composite abrasive in this example is filled with abrasive powder into the polygonal groove of the graphite mould, assembled into a composite block, placed in a six-sided roof, and synthesized under the conditions of 30,000 atmospheres and 1900°C for 15 minutes The prepared cuboid abrasive.

[0065] Wherein, the abrasive powder includes the following components by mass percentage: 55% of cubic boron nitride with a particle size of 1-5 μm, 25% of corundum with a particle size of 10-20 μm, and 10% of titanium nitride with a particle size of 10-20 μm. %, 10% cobalt powder with a particle size of 1-2 μm. After the above components are uniformly mixed, the abrasive powder is obtained.

[0066] The polygonal groove of the graphite mold used is cuboid. The engraving method of the graphite mold is the same as in Example 1, wherein the engraving depth is 1 mm, and the length and width are 1.2 mm.

[0067] The method of filling the abrasive powder and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com