Mineral fiber and carbon fiber automobile brake pad and preparation method thereof

A mineral fiber and carbon fiber technology, applied in chemical instruments and methods, friction linings, mechanical equipment, etc., can solve problems such as poor wear resistance and heat resistance, poor thermal conductivity of asbestos, and performance degradation of brake pads, etc., to achieve The data is stable, the noise is eliminated, and the performance is maintained well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

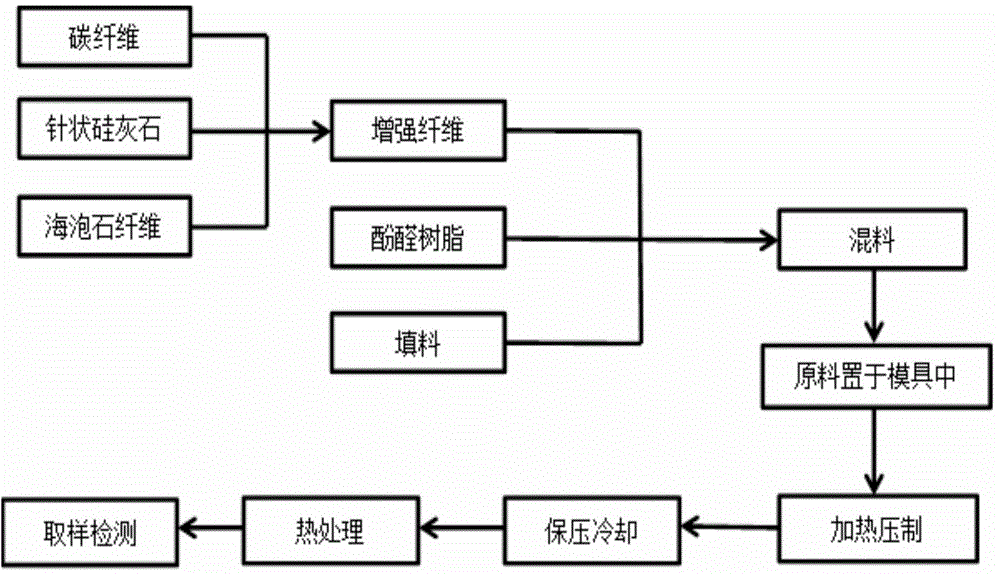

[0092] Such as figure 1 According to the preparation process shown, the weight of each component is determined according to the weight percentage of each component in the raw material, and the specific weight of each component is determined as follows: 6kg of PAN-based carbon fiber, 36kg of sepiolite fiber, 6kg of acicular wollastonite, cashew nut shell oil Modified phenolic resin 20kg, filler 32kg.

[0093] Sampling respectively according to the percentage by weight of each component in the filler, the specific weight of each component in the filler that determines 32kg is: calcium carbonate 7kg (21.88%), kaolin 4kg (12.5%), iron black 4kg (12.5%), oxidation Aluminum 3kg (9.38%), copper powder 1kg (3.12%), graphite particles 8kg (25%), friction powder 1kg (3.12%), molybdenum disulfide 4kg (12.5%). Put each component in the filler with the above weight into a high-speed mixer, mix thoroughly for 20 minutes, and make a filler.

[0094] Cut the PAN-based carbon fibers into cho...

Embodiment 2

[0097] Such as figure 1 According to the preparation process shown, the filler weight is determined according to the weight percentage of each component in the raw material, and the specific weight of each component is determined as follows: PAN-based carbon fiber 8kg, sepiolite fiber 36kg, acicular wollastonite 6kg, cashew nut shell oil modification 18kg of phenolic resin, 32kg of filler.

[0098] Sampling respectively according to the percentage by weight of each component in the filler, the specific weight of each component in the filler that determines 32kg is: calcium carbonate 7kg (21.88%), kaolin 4kg (12.5%), iron black 5kg (15.62%), oxidation Aluminum 3kg (9.38%), copper powder 1kg (3.12%), graphite particles 6kg (18.75%), friction powder 2kg (6.25%), molybdenum disulfide 4kg (12.5%). Put each component in the filler with the above weight into a high-speed mixer, mix thoroughly for 20 minutes, and make a filler.

[0099] Cut the PAN-based carbon fibers into chopped f...

Embodiment 3

[0102] Such as figure 1 According to the preparation process shown, the filler weight is determined according to the weight percentage of each component in the raw material, and the specific weight of each component is determined as follows: PAN-based carbon fiber 8kg, sepiolite fiber 30kg, acicular wollastonite 5kg, cashew nut shell oil modification 20kg of phenolic resin, 37kg of filler.

[0103] Sampling respectively according to the percentage by weight of each component in the filler, the specific weight of each component in the filler that determines 37kg is: calcium carbonate 10kg (27.03%), kaolin 4kg (10.81%), iron black 5kg (13.51%), oxidation Aluminum 3kg (8.11%), copper powder 1kg (2.7%), graphite particles 8kg (21.62%), friction powder 2kg (5.41%), molybdenum disulfide 4kg (10.81%). Put each component in the filler with the above weight into a high-speed mixer, mix thoroughly for 20 minutes, and make a filler.

[0104] Cut the PAN-based carbon fibers into chopped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com