Self-cleaning material for signal line and preparation method thereof

A self-cleaning and signal line technology, applied in the field of polymer materials, can solve the problems of signal lines that do not have self-cleaning function, no appearance, low surface energy, etc., and achieve the effect of bright appearance, reasonable process and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

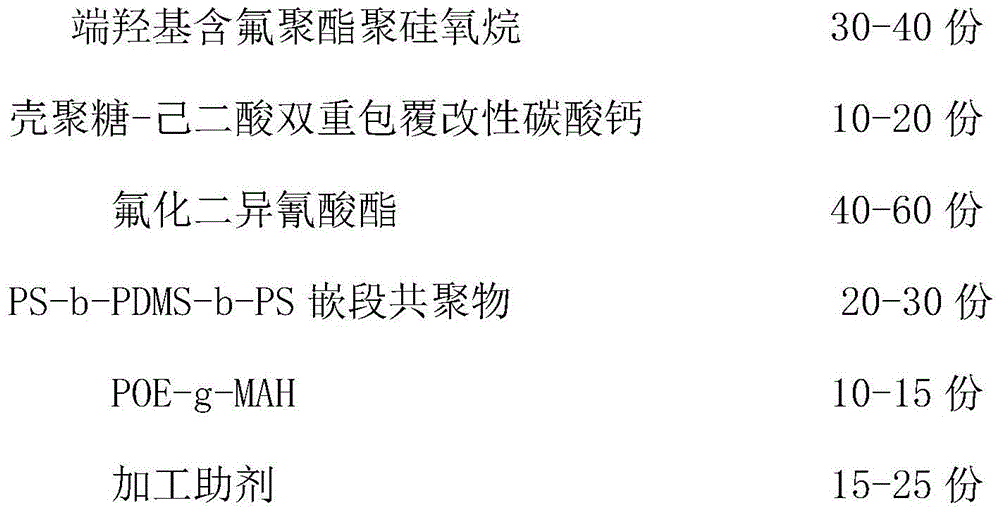

[0033] This embodiment provides a self-cleaning material for signal lines, which is made of the following components in parts by weight:

[0034]

[0035] The PS-b-PDMS-b-PS block copolymer uses n-butyllithium as an initiator, cyclohexane as a solvent, tetrahydrofuran as a polarity regulator, and dichlorodimethylsilane as a coupling agent. Polystyrene-b-polydimethylsiloxane-b-polystyrene block copolymer prepared by coupling reaction and anion polymerization. The molecular weight Mn of this polymer is 22120g / mol, and the content of polydimethylsiloxane segment is between 22-33%. Paper Polystyrene-b-polydimethylsiloxane-b-polystyrene triblock copolymer synthesis and its modified epoxy coating.

[0036] The POE-g-MAH is a maleic anhydride grafted ethylene-octene copolymer prepared by a solvothermal synthesis method, and the grafting rate is 5-10%.

[0037] The fluorinated diisocyanate is OCNCH 2 CH 2 (CF 2 )nCH 2 CH 2 NCO, OCN (CF 2 ) 3 NCO, NCOCH 2 (CF 2 ) 4 CH 2...

Embodiment 2

[0052] Embodiment 2: A self-cleaning material for signal lines and its preparation method provided in this embodiment are basically the same as in Embodiment 1, except that:

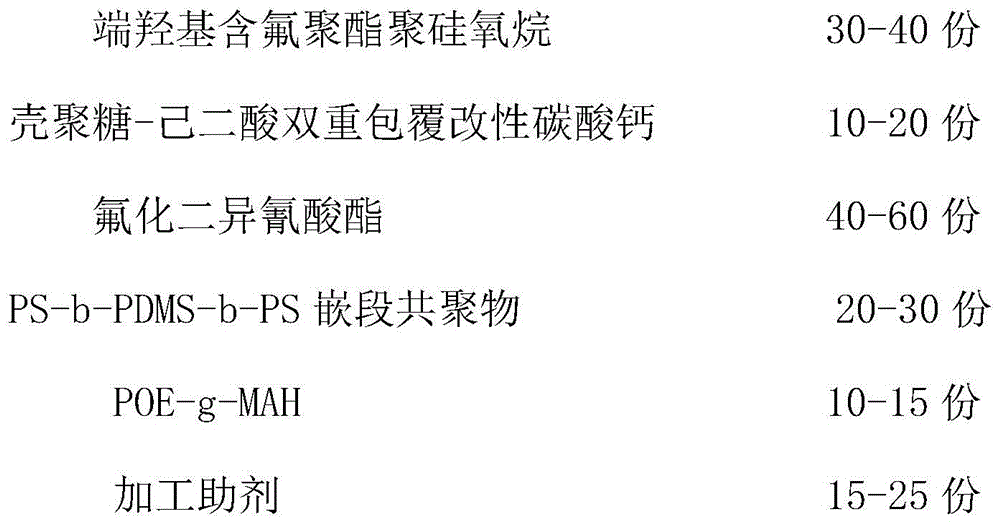

[0053] A self-cleaning material for signal lines, which is made of the following components in parts by weight:

[0054]

[0055] The PS-b-PDMS-b-PS block copolymer uses n-butyllithium as an initiator, cyclohexane as a solvent, tetrahydrofuran as a polarity regulator, and dichlorodimethylsilane as a coupling agent. Polystyrene-b-polydimethylsiloxane-b-polystyrene block copolymer prepared by coupling reaction and anionic polymerization method, wherein the content of polydimethylsiloxane segment is 22% .

[0056] The POE-g-MAH is a maleic anhydride grafted ethylene-octene copolymer prepared by a solvothermal synthesis method, and the grafting rate is 5%.

[0057] The fluorinated diisocyanate is OCNCH 2 CH 2 (CF 2 )nCH 2 CH 2 NCO, the range of n is 2, and NCOCH 2 (CF 2 ) 4 CH 2 A mixture of NC...

Embodiment 3

[0062] Embodiment 3: A self-cleaning material for signal lines and its preparation method provided in this embodiment are basically the same as Embodiments 1 and 2, except that:

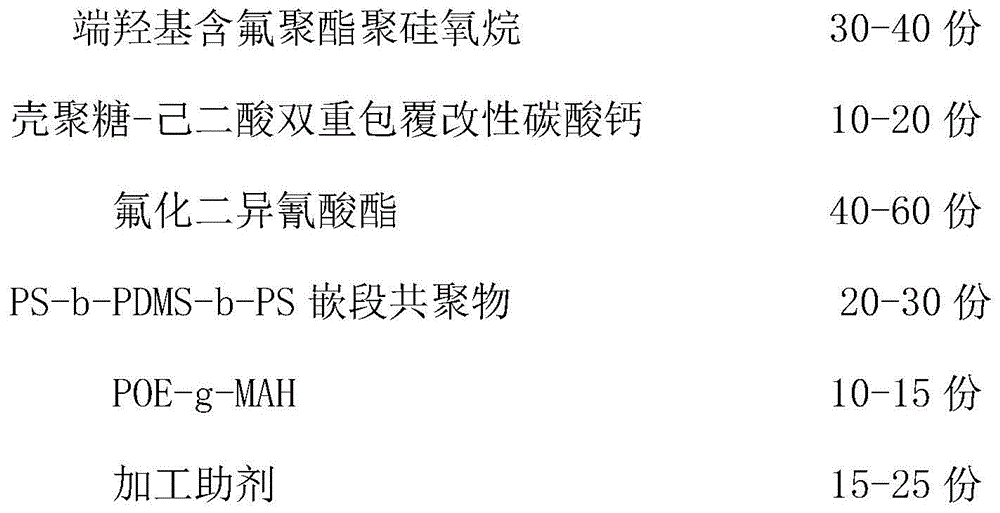

[0063] A self-cleaning material for signal lines, which is made of the following components in parts by weight:

[0064]

[0065]

[0066] The PS-b-PDMS-b-PS block copolymer uses n-butyllithium as an initiator, cyclohexane as a solvent, tetrahydrofuran as a polarity regulator, and dichlorodimethylsilane as a coupling agent. Polystyrene-b-polydimethylsiloxane-b-polystyrene block copolymer prepared by coupling reaction and anionic polymerization method, wherein the content of polydimethylsiloxane segment is 27% .

[0067] The POE-g-MAH is a maleic anhydride grafted ethylene-octene copolymer prepared by a solvothermal synthesis method, and the grafting rate is 7%.

[0068] The fluorinated diisocyanate is OCNCH 2 CH 2 (CF 2 )nCH 2 CH 2 NCO, the value range of n is 16.

[0069] The processin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com