Transparent halogen-free flame-retardant polycarbonate resin and preparation method thereof

A technology of flame-retardant polycarbonate and polycarbonate, which is applied in the fields of flame-retardant polycarbonate resin, transparent halogen-free flame-retardant polycarbonate resin and its preparation, and can solve the problem of inability to guarantee product transparency, affecting product transparency, etc. problems, easy processing and storage, excellent flame retardant effect, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0035] A method for preparing a transparent halogen-free flame-retardant polycarbonate resin, the method comprising the following steps:

[0036] (1) According to the weight percentage of the masterbatch formula ingredients in Table 1, add the raw materials into the high-speed mixer and mix them thoroughly, then place them in the screw machine, control the speed of the screw machine to 300-500rpm, and the temperature to 270-290°C , extruded and granulated to prepare a flame retardant masterbatch;

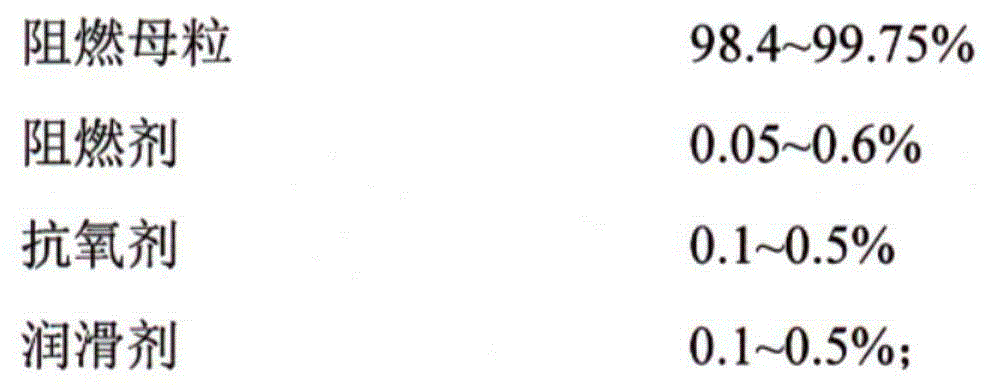

[0037] (2) Add the flame retardant masterbatch and other ingredients prepared in step (1) into the high-speed mixer according to the weight percentage of each ingredient in Table 2, and then fully mix them, then place them in the screw machine, and control the speed of the screw machine 300-500rpm, temperature 270-290°C, extruding and granulating to obtain the product.

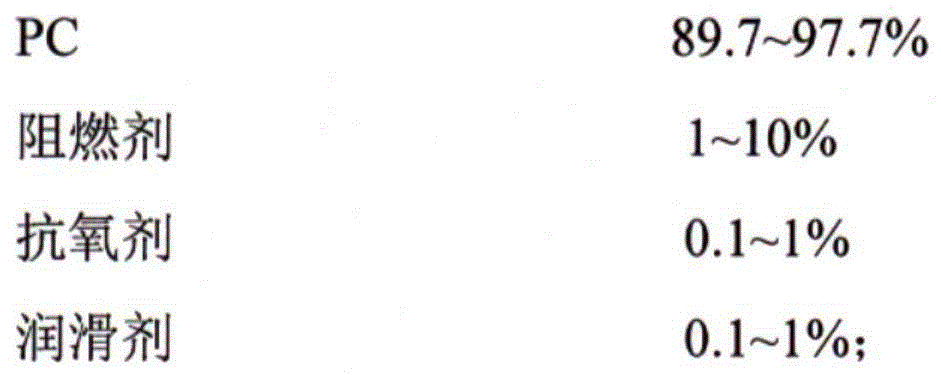

[0038] Wherein, the material composition of table 1 and table 2 is as follows:

[0039] Component A1 is PC, the...

Embodiment 7

[0069] In this embodiment, the transparent halogen-free flame-retardant polycarbonate resin includes the following ingredients in weight percent: 98.4% of flame-retardant masterbatch, 0.6% of flame retardant, 0.5% of antioxidant and 0.5% of lubricant.

[0070] Wherein, the flame retardant masterbatch includes the following components by weight percentage: 89.7% of PC, 10% of flame retardant, 0.1% of antioxidant and 0.2% of lubricant.

[0071] PC is bisphenol A polycarbonate, and the weight average molecular weight of the bisphenol A polycarbonate is 10000.

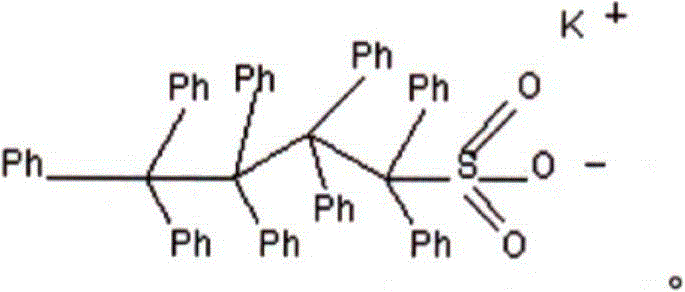

[0072] The flame retardant is potassium perphenylbutylsulfonate, the softening point of potassium perphenylbutylsulfonate is 96-100°C, the pH value is 6.6-6.8, and the thermal decomposition temperature is >410°C. The specific structural formula is as follows:

[0073]

[0074] The antioxidant is tetrakis[β-(3,5-di-tert-butyl 4-hydroxyphenyl) propionate] pentaerythritol, and the lubricant is silane polymer.

[0075] The...

Embodiment 8

[0083] In this embodiment, the transparent halogen-free flame-retardant polycarbonate resin includes the following ingredients in weight percentage: 99.75% of flame-retardant masterbatch, 0.05% of flame retardant, 0.1% of antioxidant and 0.1% of lubricant.

[0084] Wherein, the flame retardant masterbatch includes the following components by weight percentage: 97.7% of PC, 1% of flame retardant, 1% of antioxidant and 0.3% of lubricant.

[0085] PC is bisphenol A polycarbonate, and the weight average molecular weight of the bisphenol A polycarbonate is 40,000.

[0086] The flame retardant is potassium perphenylbutylsulfonate, the softening point of potassium perphenylbutylsulfonate is 96-100°C, the pH value is 6.6-6.8, and the thermal decomposition temperature is >410°C. The specific structural formula is as follows:

[0087]

[0088] The antioxidant is pentaerythritol bisphosphite bis (2,4-di-t-butylphenyl) ester, and the lubricant is methylene bis stearic acid amide and N,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com