TiC particle enhancement mode complex phase tissue high-ductility wear-resisting steel plate and manufacturing method thereof

A wear-resistant steel plate and enhanced technology, applied in the field of alloy steel, can solve the problems of poor welding performance and processing performance of high-hardness wear-resistant steel, and difficulty in meeting equipment manufacturing requirements, so as to improve wear resistance and solve the problem of wear resistance and Workability and weldability, the effect of resolving outstanding contradictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

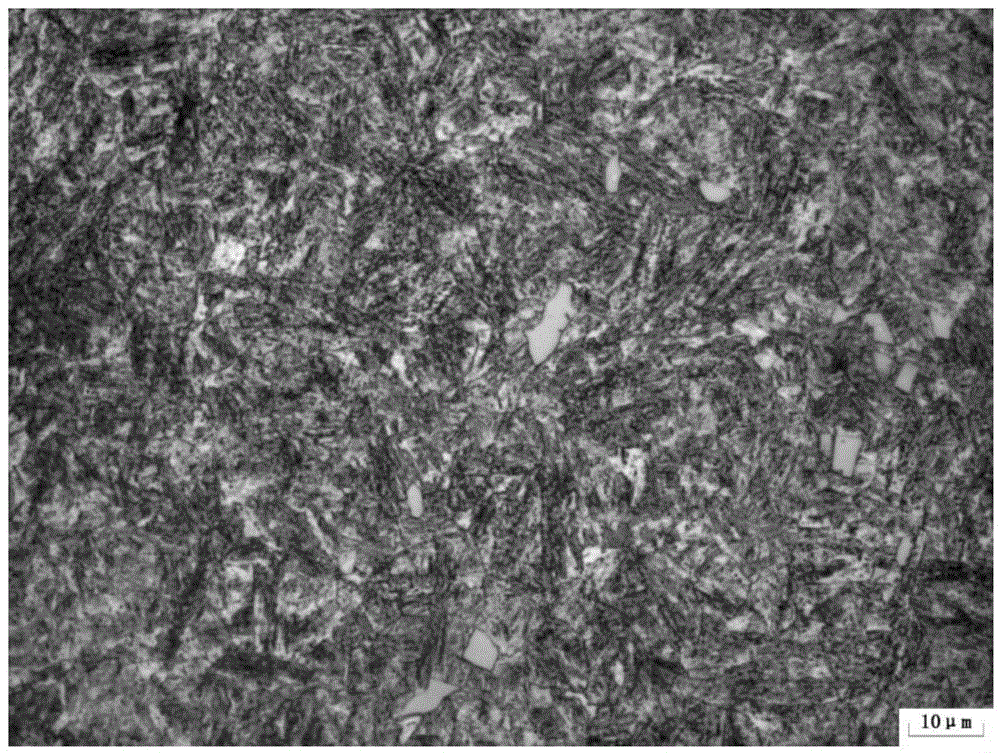

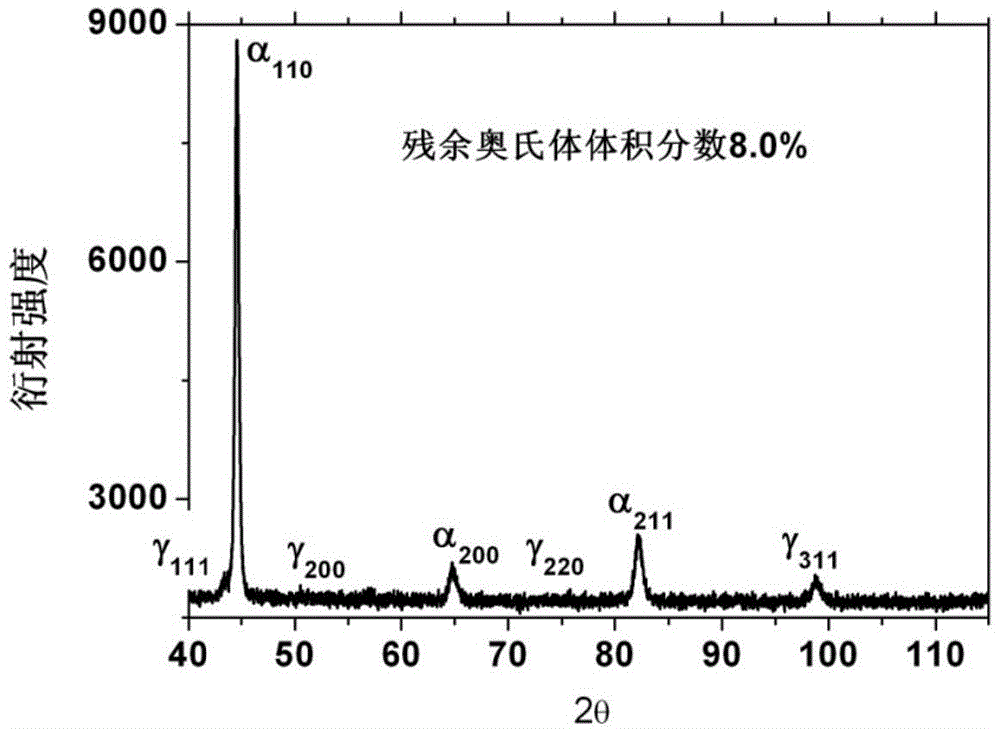

Embodiment 1

[0030] Embodiment 1: The chemical composition of the present invention is C: 0.32; Si: 1.20; Mn: 1.95; Ni: 0.25; Mo: 0.18; Ti: 0.52; Cu: 0.36; B: 0.0021; ; P: 0.010; the balance is Fe and unavoidable impurities. Manufacturing process: converter smelting, LF refining, RH refining, slab continuous casting, rolling by medium and heavy plate rolling mill, heating furnace heating temperature 1200 ℃, finishing rolling temperature 875 ℃, rolling thickness 40mm, air cooling after rolling. Heat treatment process: austenitizing temperature 900°C, holding time 0.5 hours, air cooling to room temperature, then tempering at 200°C for 1 hour and air cooling to room temperature.

Embodiment 2

[0031] Embodiment 2: The chemical composition of the present invention is C: 0.35; Si: 1.12; Mn: 1.52; Cr: 0.48; Ni: 0.48; Mo: 0.20, Ti, 0.62, B: 0.0018; ; P: 0.008; the balance is Fe and unavoidable impurities. Manufacturing process: converter smelting, LF refining, slab continuous casting, rolling by medium and heavy plate rolling mill, heating furnace heating temperature 1220°C, finishing rolling temperature 900°C, rolling thickness 60mm, air cooling after rolling. Heat treatment process: austenitizing temperature 900°C, holding time 0.5 hours, water mist cooling to below 400°C, then air cooling to room temperature, then tempering at 200°C for 1 hour and air cooling to room temperature.

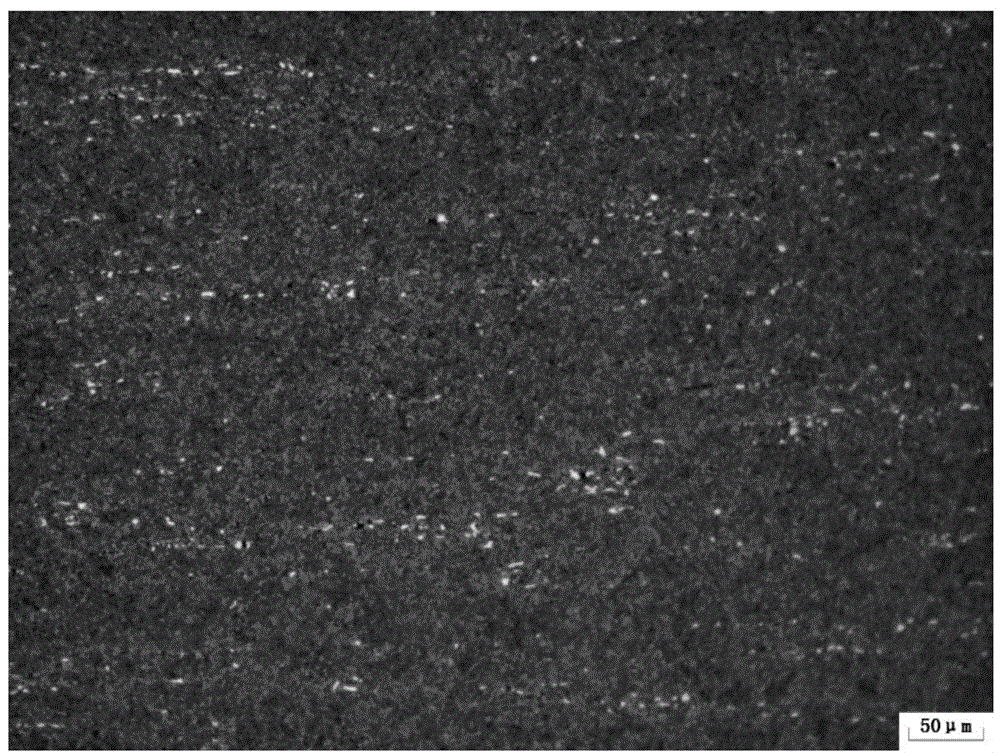

Embodiment 3

[0032]Embodiment 3: The chemical composition of the present invention is C: 0.30; Si: 0.45; Mn: 1.05; Cr: 0.68; Ni: 0.38; Mo: 0.45; Ti: 0.58; B: 0.0018; ; P: 0.015; the balance is Fe and unavoidable impurities. Manufacturing process: converter smelting, LF refining, slab continuous casting, rolling by medium and heavy plate rolling mill, heating furnace heating temperature 1200 ℃, finishing rolling temperature 885 ℃, rolling thickness 30mm, air cooling after rolling. Heat treatment process: austenitizing temperature 880°C, holding time 0.5 hours, oil quenching with No. 20 engine oil to the bottom, then tempering at 200°C for 1 hour and air cooling to room temperature.

[0033] Examples of the present invention and Hardox450 mechanical properties and wear resistance testing results are shown in Table 1.

[0034] Table 1 embodiment of the present invention and Hardox450 mechanical property and wear resistance test result

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com