Artificial colored sand coloring agent, artificial colored sand using coloring agent, preparation method of coloring agent, and preparation method of artificial colored sand

A technology of artificial colored sand and compound coloring, applied in the fields of functional sand, compound colorant and artificial colored sand, can solve the problems of poor wear resistance and poor compatibility of colored sand, and achieve stable and uniform color and satisfactory drying performance at room temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] After long-term repeated research, the applicant found that the key material that affects the performance and processing technology of artificial colored sand lies in the binder. An excellent binder needs to meet the following conditions: (1) It has super permeability, can penetrate into the interior of quartz sand, and is an artificial colored sand binder that dries at room temperature; (2) The binder must have a certain degree of hydrophilicity , to ensure compatibility with water-based resin emulsions; (3) High film-forming strength.

[0021] In order to meet the above requirements, we have successfully solved these problems through repeated research and experiments. The key lies in the way of compounding inorganic binder water glass and organic resin emulsion. The screening process of key binders and additives is set out below.

[0022] (1), the selection of the first binder - water glass

[0023] Water glass, commonly known as sodium silicate, is a water-soluble ...

Embodiment 2

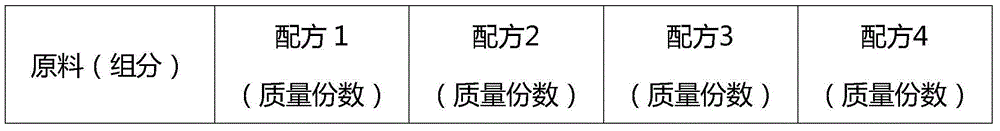

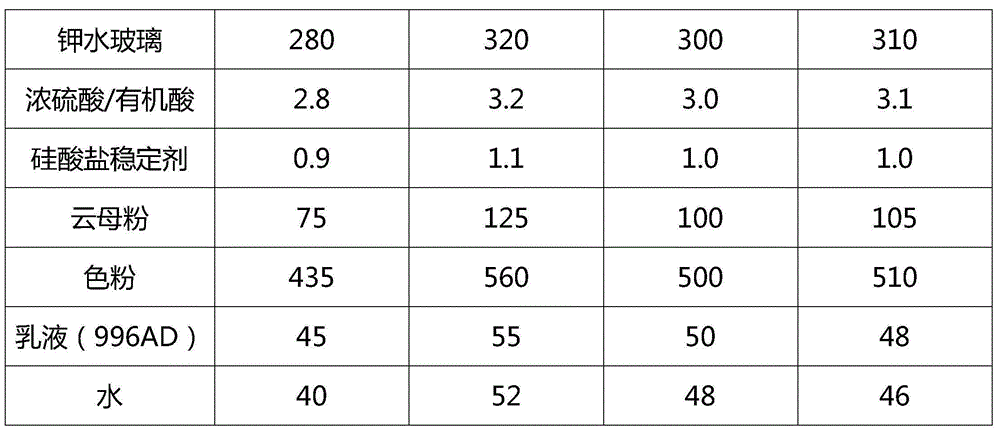

[0045] Through the selection of materials in Example 1, the colorant formula determined by the present invention is shown in Table 3.

[0046] Table 3 Composite Colorant Formula

[0047]

[0048]

Embodiment 3

[0050] The preparation technology of composite coloring agent of the present invention, comprises the steps:

[0051] 1) Water glass acid modification step, adding inorganic acid or organic acid to water glass, and stirring for 8-15 minutes at a speed of 400-500 rpm;

[0052] 2) Add stabilizer step, drop filler into modified water glass, such as 1250 mesh mica powder, the toner of required color, drop into stabilizer while stirring, stir evenly under the rotating speed condition of 400-500 rpm Finally, disperse at a high speed for 8-15 minutes at a speed of 1450-1550 rpm;

[0053] 3) In compounding step, add water-based resin emulsion into the above-mentioned mixture obtained after high-speed dispersion, and stir to make it uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com