Coating composition with functions of friction resistance and wear resistance

A wear-resistant coating and composition technology, applied in coatings and other directions, can solve the problems of high cost, low friction coefficient, fast failure of laser cladding technology, improve transmission efficiency and service life, high reduction friction coefficient, low friction coefficient, etc. The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 Preparation of friction-reducing and wear-resistant coating composition

[0026] Preparation of materials:

[0027] (1) Titanium carbide (TiC) powder, particle size 2 μm ~ 4 μm, commercially available, produced by Zhuzhou Jiangtung Boda Hard Surface Materials Co., Ltd. The TiC content is 99.52%, and the balance is free C, O, N, Fe, Al, Na and other impurities.

[0028] (2) Nickel coated calcium fluoride (CaF 2 -Ni) powder: produced by Beijing Shengbo Gaotai Optical Technology Co., Ltd., made of CaF with a particle size of 35 μm to 37 μm 2 The nickel coating treatment is carried out by the nickel oxyhydroxide decomposition method, and the particle size of the product nickel-coated calcium fluoride powder is 75 μm to 128 μm.

[0029] (3) Nickel-coated graphite (graphite-Ni) powder: commercially available, produced by Shanghai Yifan Graphite Co., Ltd., nickel-coated graphite powder with a particle size of 3 μm to 5 μm is treated with nickel hydroxide decomp...

Embodiment 2

[0034] Embodiment 2 Formation of coating

[0035] The above-mentioned coating composition is deposited on the surface of the steel friction member by plasma spraying technology, and the process is as follows:

[0036] (1) First use emery on 45 # The surface of steel (or other carbon steel) friction components is sandblasted, and the surface roughness after sandblasting is Ra=3.5μm~4.5μm.

[0037] (2) Use DH1080 plasma spraying equipment to spray the coating composition of Example 1 on the surface of the friction member, process parameters: current 600A, voltage 30V, spraying distance 100mm, nozzle moving speed 0.01m / s, spraying thickness 350μm~450μm .

[0038] (3) Through grinding, the surface of the sprayed coating of the friction member is processed to the required precision.

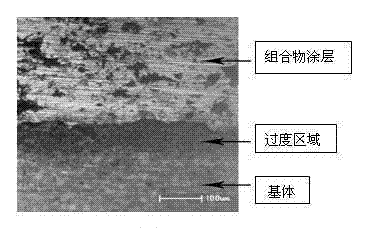

[0039] Microstructural analysis of coatings such as figure 1 , the coating structure is dense, and it is firmly combined with the substrate. The microhardness of the coating reaches HV600.6. The ...

Embodiment 3

[0040] Embodiment 3 performance test of coating

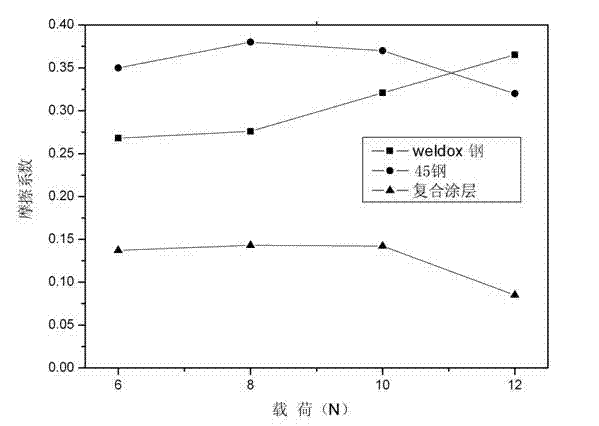

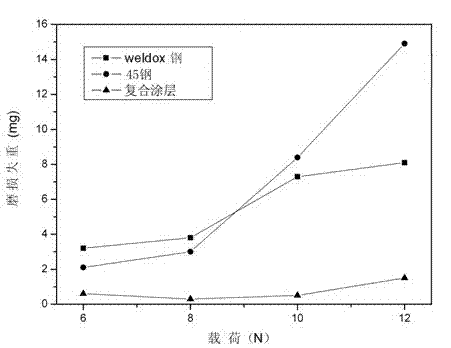

[0041] In the test, the GCr15 steel ball is used as the pair of rubbing parts, and the coating of embodiment 2, 45 # Steel, weldox960 high-strength alloy structural steel for friction.

[0042] The test conditions are: room temperature (25°C), relative air humidity of RH60%, dry friction, sliding speed of 0.1m / s, followed by 6N, 8N, 10N, 12N (the corresponding contact stress is 12.7MPa, 38.2MPa, 63.7MPa, 127.4MPa) load test, the friction and wear test results are as follows Figure 2 ~ Figure 4 shown.

[0043] The variation curves of the three friction coefficients with the load are as follows: figure 2 , the coefficient of friction of the coating composition coating of the present invention is in the scope of 0.085~0.14, 45 # The friction coefficient of steel is between 0.32 and 0.38, and the friction coefficient of weldox960 high-strength alloy structural steel imported from Sweden is between 0.26 and 0.37. It can be se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com