Coating with high-temperature resistance and salt fog resistance for engine exhaust pipe and preparation method of coating

A salt spray-resistant and high-temperature-resistant technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., to achieve the effect of blocking corrosion damage and solving corrosion drawbacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

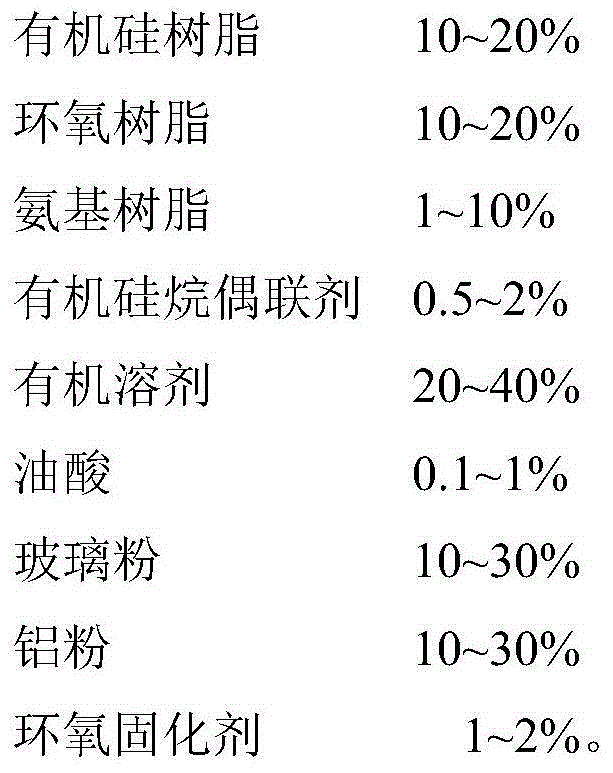

[0023]

[0024]

[0025] Wherein the organic solvent is a mixture of xylene and n-butanol, and the mass ratio of the two is xylene:n-butanol=3:1.

[0026] Among them, the epoxy curing agent is m-phenylenediamine and diethylene triamine, and the mass ratio of the two is m-phenylenediamine:diethylene triamine=1:1.

[0027] Wherein the composition of the glass powder is calculated by the following mass percentages after selection and adjustment: Al 2 o 3 content is 4%, ZnO content is 28%, B 2 o 3 Content is 30%, P 2 o 5 The content of MgO is 18%, the content of BaO is 6%, the content of CaO is 7%, the content of SrO is 2%, and the content of MgO is 5%. The preparation steps are: mix the raw materials according to the above ratio and put them into the crucible , heated in an electric furnace at 1000°C for 30 minutes, and immediately quenched the obtained glass liquid in deionized water, and finally dried and ground the obtained glass block for later use.

[0028] The t...

Embodiment 2

[0035]

[0036] Wherein the organic solvent is a mixture of xylene and n-butanol, and the mass ratio of the two is xylene:n-butanol=3:1.

[0037] Among them, the epoxy curing agent is m-phenylenediamine and diethylene triamine, and the mass ratio of the two is m-phenylenediamine:diethylene triamine=1:1.

[0038] The preparation process of glass powder and coating is as above-mentioned embodiment 1.

[0039] During construction, mix components A and B evenly for painting, then put it in an oven, and undergo a process of gradually increasing the temperature and curing, that is, curing at 30°C for 3 hours, and then raising the temperature to 180°C for 2 hours.

[0040] According to the experimental results, the coating is coated on the tinplate sheet, the temperature resistance of the coating can reach 700°C, and the adhesion is grade 1. After the thermal cycle test, the 24h salt spray test shows that the base metal has no corrosion lesions.

Embodiment 3

[0042]

[0043] Wherein the organic solvent is a mixture of xylene and n-butanol, and the mass ratio of the two is xylene:n-butanol=3:1.

[0044] Among them, the epoxy curing agent is m-phenylenediamine and diethylene triamine, and the mass ratio of the two is m-phenylenediamine:diethylene triamine=1:1.

[0045] The preparation process of glass powder and coating is as above-mentioned embodiment 1.

[0046] During construction, mix components A and B evenly for painting, then put it into an oven, and undergo a process of gradually increasing the temperature and curing, that is, curing at 30°C for 2 hours, and then raising the temperature to 170°C for 2 hours.

[0047] According to the experimental results, the coating is coated on the tinplate sheet, the temperature resistance of the coating can reach 600°C, and the adhesion is grade 2. After the thermal cycle test, the 24h salt spray test shows that a small amount of corrosion lesions appear on the base metal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com