Blocking thin film used for encapsulation of flexible electronic product and preparation method for blocking thin film

A barrier film and electronic product technology, applied in the field of barrier film and its preparation, can solve the problems of poor bending resistance of barrier film, failure of flexible electronic products, insufficient water vapor barrier performance, etc., to achieve good barrier performance, reinforcement and protection Inorganic coating, less defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The barrier film in this embodiment includes in turn a 38 micron thick PET base material layer, a 20 nanometer thick silicon oxide coating, an 800 nanometer thick high toughness flexible organic coating and a 600 nanometer thick titanium oxide coating. Its preparation method is as follows:

[0059] A, on one side of 38 micron thick PET base material layer, deposit one deck of 20 nanometer thick silicon oxide with PECVD, structure is SiOx (x=1-2);

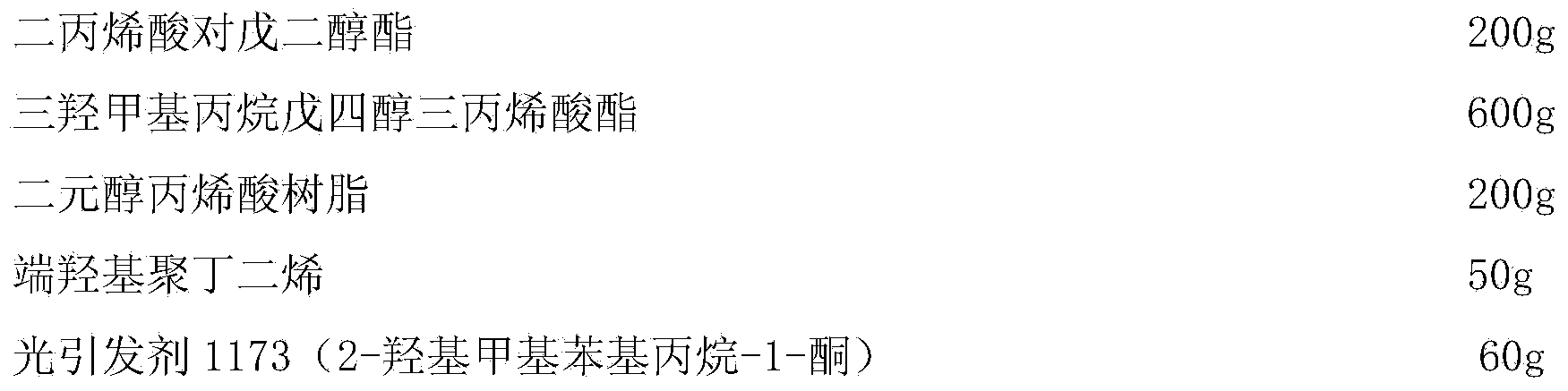

[0060] b. Coat an organic composition with a proper thickness on the surface of the silicon oxide coating with a wire bar, and use a concentrated high-pressure mercury lamp (80W / cm) at 600mJ / cm 2 It is irradiated with high irradiation energy to obtain a highly tough and flexible organic coating with a thickness of 800 nanometers;

[0061] c. Deposit a layer of titanium oxide with a thickness of 600 nanometers on the surface of the flexible organic coating by PECVD to obtain a barrier film Z-1#. Measure its performance.

[...

Embodiment 2

[0072] The barrier film in this embodiment includes a 38 micron thick PET base material layer, a 200 nanometer thick silicon oxide coating, a 1000 nanometer thick high toughness flexible organic coating and a 600 nanometer thick silicon oxide coating. Its preparation method is as follows:

[0073] A, on one side of 38 micron thick PET base material layer, deposit a layer of 200 nanometer thick silicon oxide with PECVD, structure is SiOx (x=1-2);

[0074] b. Coat an organic composition with a proper thickness on the surface of the silicon oxide coating with a wire bar, and use a concentrated high-pressure mercury lamp (80W / cm) at 600mJ / cm 2 It is irradiated with high irradiation energy to obtain a highly tough and flexible organic coating with a thickness of 1000 nanometers;

[0075] c. Deposit a layer of silicon oxide with a thickness of 600 nanometers on the surface of the flexible organic coating by PECVD to obtain the barrier film Z-2#. Measure its performance.

[0076] Wh...

Embodiment 3

[0086] The barrier film in this embodiment includes a 125 micron thick PET base material layer, a 50 nanometer thick silicon nitride coating, a 400 nanometer thick high toughness flexible organic coating and a 300 nanometer thick silicon nitride coating. Its preparation method is as follows:

[0087] a. On one side of the 125 micron thick PET base material layer, a layer of 50 nanometer thick silicon nitride is deposited by PECVD, and the structure is Si 3 Nx(x=3-4);

[0088] b. Use a wire bar to coat an organic composition of appropriate thickness on the surface of the silicon nitride coating, and use a concentrated high-pressure mercury lamp (80W / cm) at 600mJ / cm 2 It is irradiated with high irradiation energy to obtain a highly tough and flexible organic coating with a thickness of 400 nanometers;

[0089] c. Deposit a layer of silicon nitride with a thickness of 300 nm on the surface of the flexible organic coating by PECVD to obtain a barrier film Z-3#. Measure its perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com