A kind of pretreatment method that utilizes bagasse to ferment and produce butanol

A pretreatment, bagasse technology, applied in the field of pretreatment of butanol produced by fermentation of bagasse, to achieve the effect of low production cost, no corrosion of equipment, and mild pretreatment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

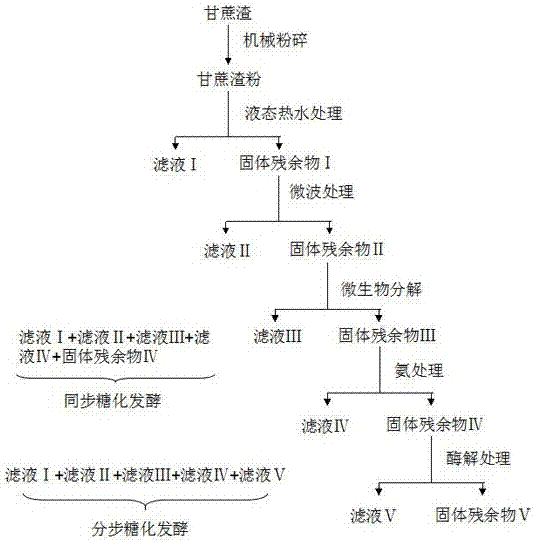

Method used

Image

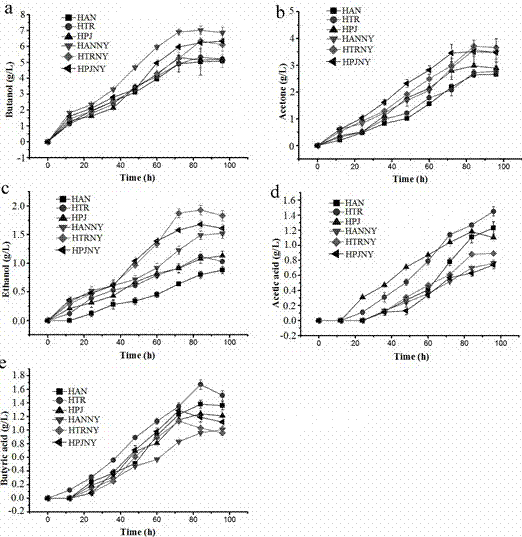

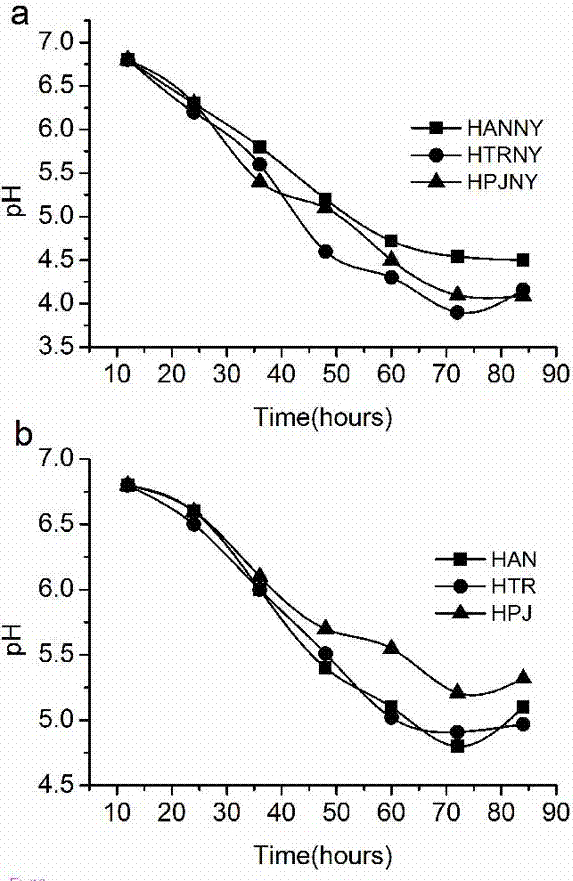

Examples

Embodiment 1

[0048] 1) Cut 500g of sugarcane to a length of 5-10cm, dry at 65±2°C for 2 days, then pulverize and pass through a 20-mesh sieve to obtain bagasse powder with a particle size of less than 830μm;

[0049] 2) Soak the product obtained in step 1) in 2L of water at room temperature for 12 hours, then preheat with steam for 45 seconds, then add liquid hot water, react at 200±3°C for 1 hour, filter after reaction, collect filtrate I and solid residue I;

[0050] 3) Adjust the humidity of the solid residue obtained in step 2) to 40%, and place it in a three-necked round-bottomed flask, then pass through nitrogen to exclude oxygen, and place it at 4 °C for 12 hours, and then place the reactor in a microwave pyrolysis furnace React at 120 °C for 7 min, discharge the hot gas, soak the reaction product with 90% ethanol after the temperature drops to room temperature, and then filter to collect the filtrate II and solid residue II;

[0051] 4) Dry the solid residue obtained in step 3), t...

Embodiment 2

[0058] 1) Cut 500g of sugarcane to a length of 5-10cm, dry at 65±2°C for 2 days, then pulverize and pass through a 20-mesh sieve to obtain bagasse powder with a particle size of less than 830μm;

[0059] 2) Soak the product obtained in step 1) in 2L of water at room temperature for 12 hours, then preheat with steam for 45 seconds, then add liquid hot water, react at 200±3°C for 1 hour, filter after reaction, collect filtrate I and solid residue I;

[0060] 3) Adjust the humidity of the solid residue obtained in step 2) to 40%, and place it in a three-necked round-bottomed flask, then pass through nitrogen to exclude oxygen, and place it at 4 °C for 8 hours, and then place the reactor in a microwave pyrolysis furnace React at 120 °C for 7 min, discharge the hot gas, soak the reaction product with 90% ethanol after the temperature drops to room temperature, and then filter to collect the filtrate II and solid residue II;

[0061] 4) Dry the solid residue obtained in step 3), th...

Embodiment 3

[0068] 1) Cut 500g of sugarcane to a length of 5-10cm, dry at 65±2°C for 2 days, then pulverize and pass through a 20-mesh sieve to obtain bagasse powder with a particle size of less than 830μm;

[0069] 2) Soak the product obtained in step 1) in 2L of water at room temperature for 12 hours, then preheat with steam for 45 seconds, then add liquid hot water, react at 200±3°C for 1 hour, filter after reaction, collect filtrate I and solid residue I;

[0070] 3) Adjust the humidity of the solid residue obtained in step 2) to 40%, and place it in a three-necked round-bottomed flask, then pass through nitrogen to exclude oxygen, and place it at 4 °C for 10 hours, and then place the reactor in a microwave pyrolysis furnace React at 120 °C for 7 min, discharge the hot gas, soak the reaction product with 90% ethanol after the temperature drops to room temperature, and then filter to collect the filtrate II and solid residue II;

[0071] 4) Dry the solid residue obtained in step 3), t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com