A self-layering epoxy paint

An epoxy paint and self-layering technology, applied in the field of epoxy paint, can solve problems such as short service life, long time, and affecting the quality of composite coatings, reduce production costs, facilitate industrial production and application, and solve interlayer adhesion. The effect of focusing on the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

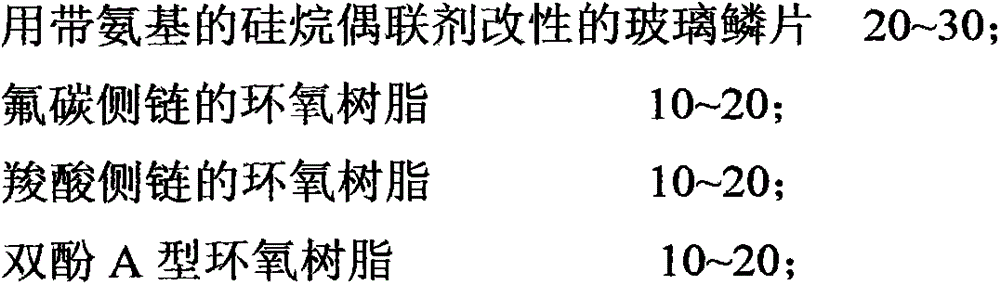

Method used

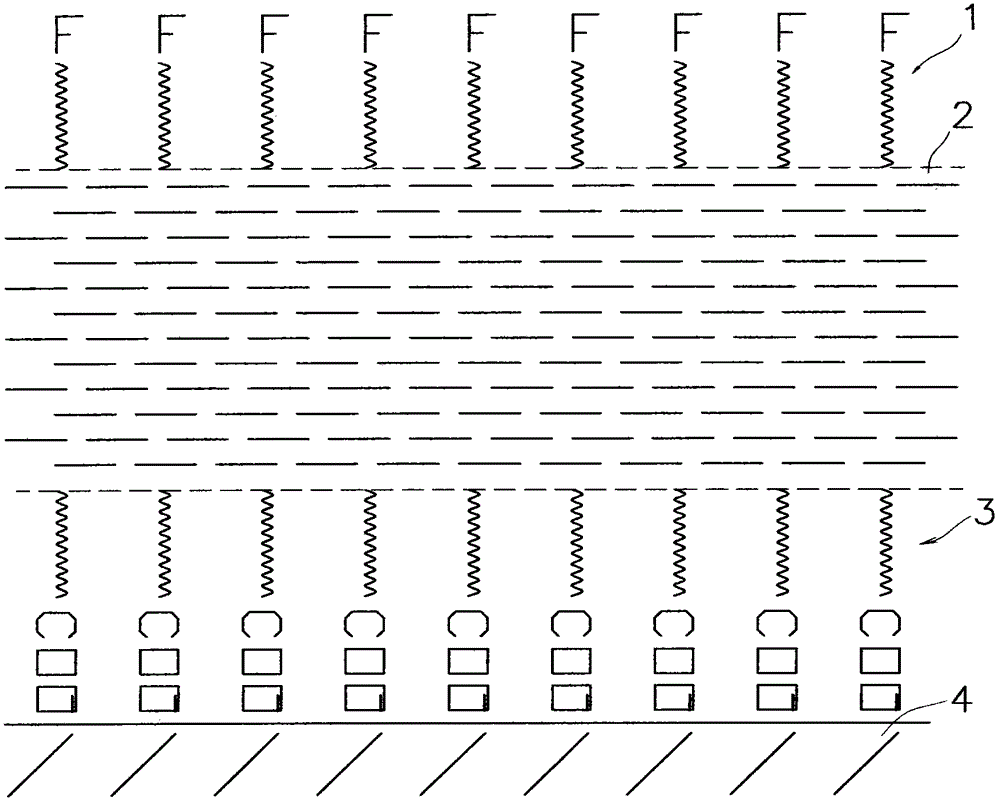

Image

Examples

Embodiment 1

[0037] Vinyl ester epoxy resin was distilled under reduced pressure at 100°C for 2 hours to remove water in the epoxy resin. Add vinyl ester epoxy resin (10g) and 1H, 1H, 2H-perfluoro-1-dodecene (10g) that have been dehydrated in a three-necked flask equipped with a thermometer, a reflux device, and nitrogen protection, and add Azobisisobutyronitrile (AIBN) (0.1 g) was reacted at 75°C for 4 hours. Use the solvent N, N dimethylacetamide halfway to adjust the viscosity of the system, and add 0.05g AIBN twice. The result is an epoxy resin with fluorocarbon side chains. The vinyl ester epoxy resin is methacrylic acid vinyl ester resin, purchased from Wuxi Jiunai Anticorrosion Material Co., Ltd.; the 1H, 1H, 2H-perfluoro-1-dodecene was purchased from Aladdin Reagent; the azobisisobutyronitrile (AIBN) was purchased from Aladdin reagent.

Embodiment 2

[0039] Vinyl ester epoxy resin was distilled under reduced pressure at 100°C for 2 hours to remove water in the epoxy resin. Add vinyl ester epoxy resin (10g) and 1H, 1H, 2H-perfluoro-1-decene (9g) that have been dehydrated in a three-necked flask equipped with a thermometer, a reflux device, and nitrogen protection, and add azo Diisobutyronitrile (AIBN) (0.08g) was reacted at 80°C for 4 hours. The viscosity of the system was adjusted with the solvent dioxane in the middle, and 0.03 g of AIBN was added twice. The result is an epoxy resin with fluorocarbon side chains. The vinyl ester epoxy resin is an acrylic vinyl ester resin, which is purchased from Wuxi Guangming Chemical Co., Ltd.; the 1H, 1H, 2H-perfluoro-1-decene is purchased from Aladdin reagent; the Azobisisobutyronitrile (AIBN) was purchased from Aladdin reagents.

Embodiment 3

[0041]Vinyl ester epoxy resin was distilled under reduced pressure at 100°C for 2 hours to remove water in the epoxy resin. Add vinyl ester epoxy resin (10g) and 11-dodecenoic acid (5g) that have been dehydrated in a three-necked flask equipped with a thermometer, a reflux device, and nitrogen protection, and add azobisisobutyronitrile (AIBN) (0.05 g), react at 70°C for 5 hours. The viscosity of the system was adjusted with the solvent xylene halfway, and 0.02 g of AIBN was added in two steps. The result is an epoxy resin with carboxylic acid side chains. The vinyl ester epoxy resin is methacrylic acid vinyl ester resin, which is purchased from Wuxi Jiunai Anticorrosion Material Co., Ltd.; the 11-dodecenoic acid is purchased from Aladdin reagent; the azobis Isobutyronitrile (AIBN) was purchased from Aladdin reagents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com