Slurry composition for negative electrode of lithium ion secondary battery

A secondary battery, lithium ion technology, applied in secondary batteries, battery electrodes, lithium batteries, etc., can solve the problems of inability to uniformly disperse, agglomeration of alloy active materials, deterioration of battery characteristics such as cycle characteristics, etc., and achieve high temperature cycling. Excellent properties, suppression of volume expansion, and excellent bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0314] [1] Manufacture of water-soluble polymer (B1)

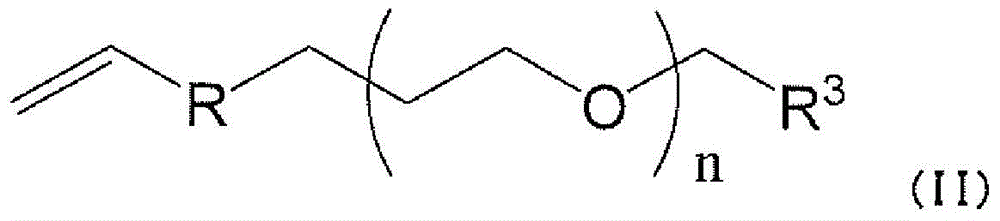

[0315] Add 25 parts of methacrylic acid (ethylenically unsaturated carboxylic acid monomer), 2,2,2-trifluoroethyl methacrylate (fluorine-containing (meth)acrylate monomer) into a 5MPa pressure-resistant container with a stirrer ) 10 parts, ethyl acrylate ((meth)acrylate monomer) 58.5 parts, 2-acrylamide-2-methylpropanesulfonic acid (ethylenically unsaturated sulfonic acid monomer) 5 parts, polyoxyalkylene Alkenyl ether ammonium sulfate (reactive surfactant monomer, manufactured by Kao, trade name "Latemul PD-104") 1.5 parts, tert-dodecyl mercaptan (chain transfer agent) 0.2 parts, ion-exchanged water 150 parts and 0.5 parts of potassium persulfate (polymerization initiator) were stirred sufficiently, and then heated to 50° C. to initiate polymerization. When the polymerization conversion ratio reached 99.0% or more, cooling was performed to terminate the reaction, and a mixture containing the water-dispersed polymer (B1...

Embodiment 2

[0337] In the manufacture of the slurry composition for negative electrodes in step [3], the addition amount of the water-soluble polymer (B1) was set to 0.3 parts, and the addition amount of the water-soluble polymer (B2) was set to 0.2 parts, and the Except for the slurry composition for negative electrodes, it carried out similarly to Example 1, and manufactured the negative electrode and the lithium ion secondary battery. The results are shown in Table 1.

Embodiment 3

[0339] In the manufacture of the slurry composition for negative electrodes in step [3], the addition amount of the water-soluble polymer (B1) was set to 1.08 parts, and the addition amount of the water-soluble polymer (B2) was set to 0.72 parts, and the Except for the slurry composition for negative electrodes, it carried out similarly to Example 1, and manufactured the negative electrode and the lithium ion secondary battery. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com