Composite LiFePO4/C cathode material for lithium ion battery and preparation method for composite LiFePO4/C cathode material

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor processing performance, low conductivity, low density, etc., to eliminate voids and looseness, improve uniformity, Density-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

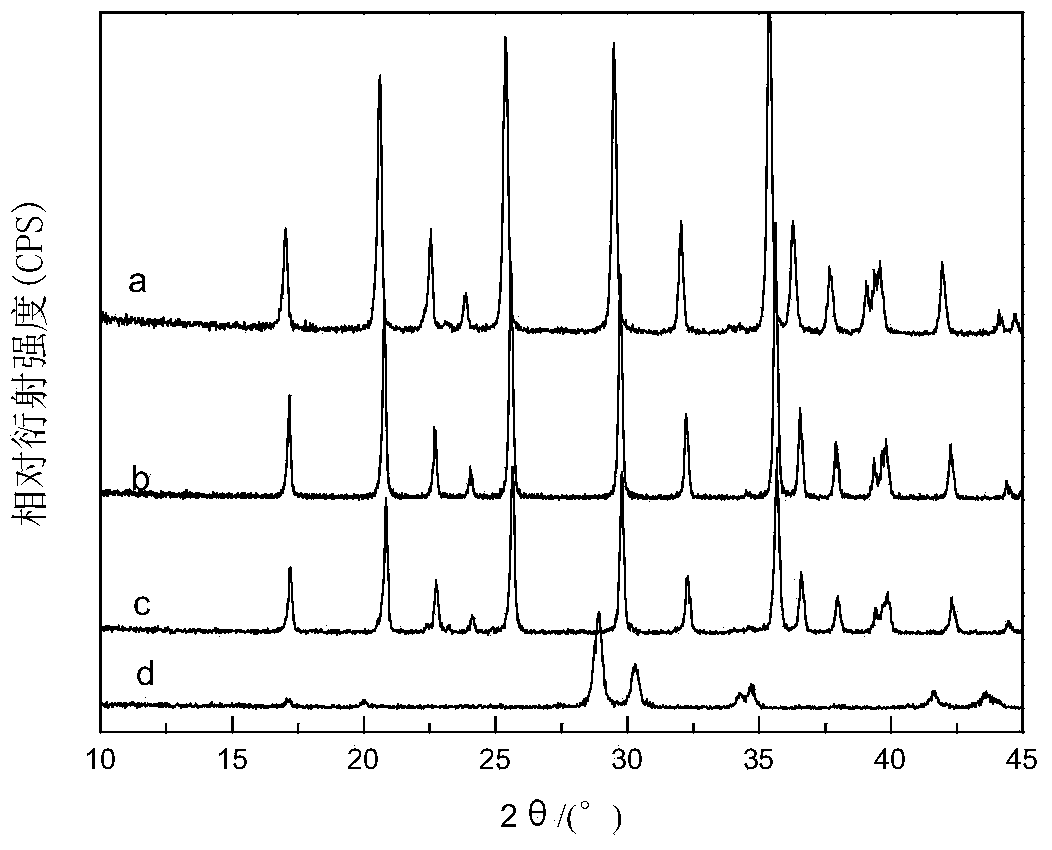

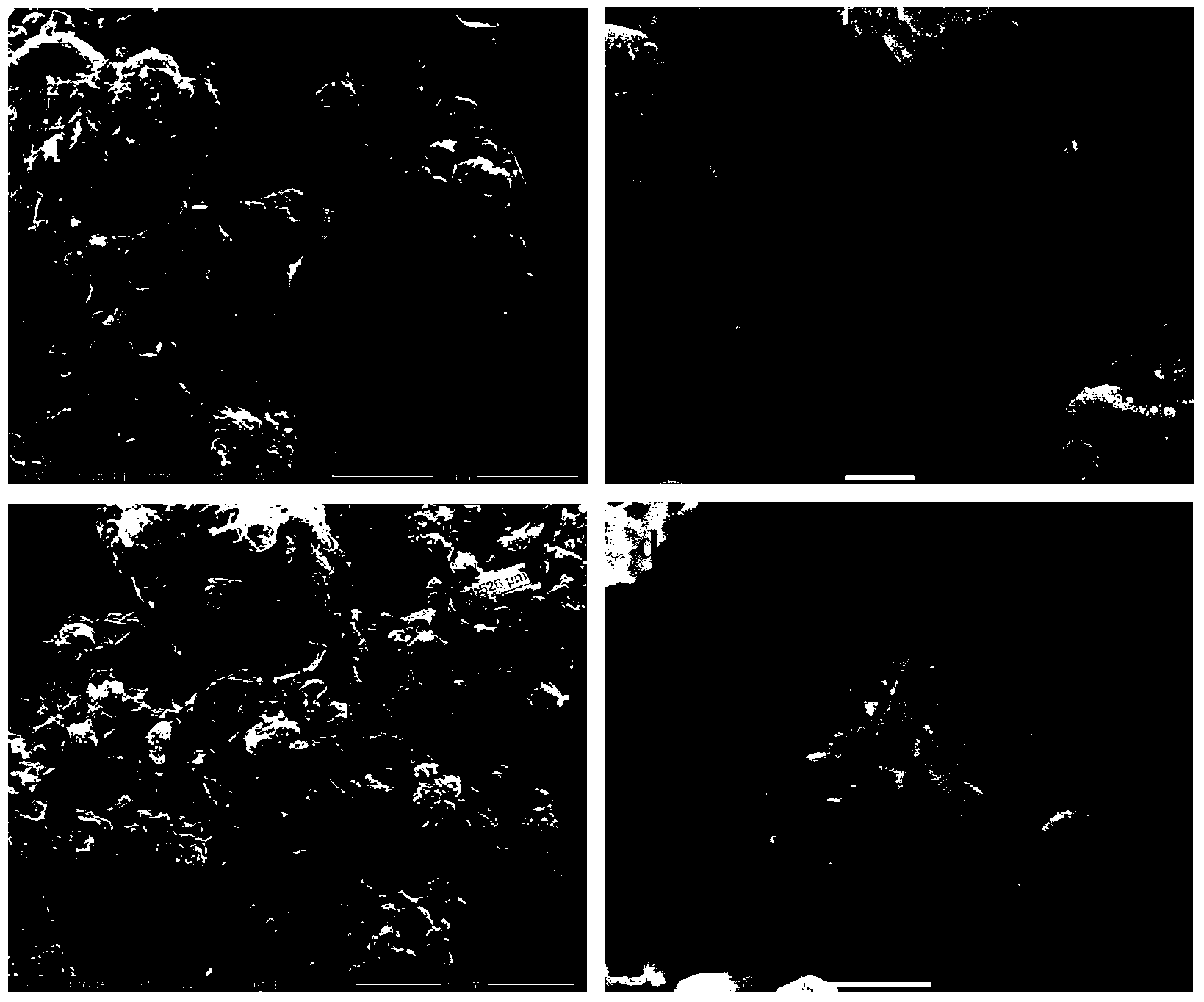

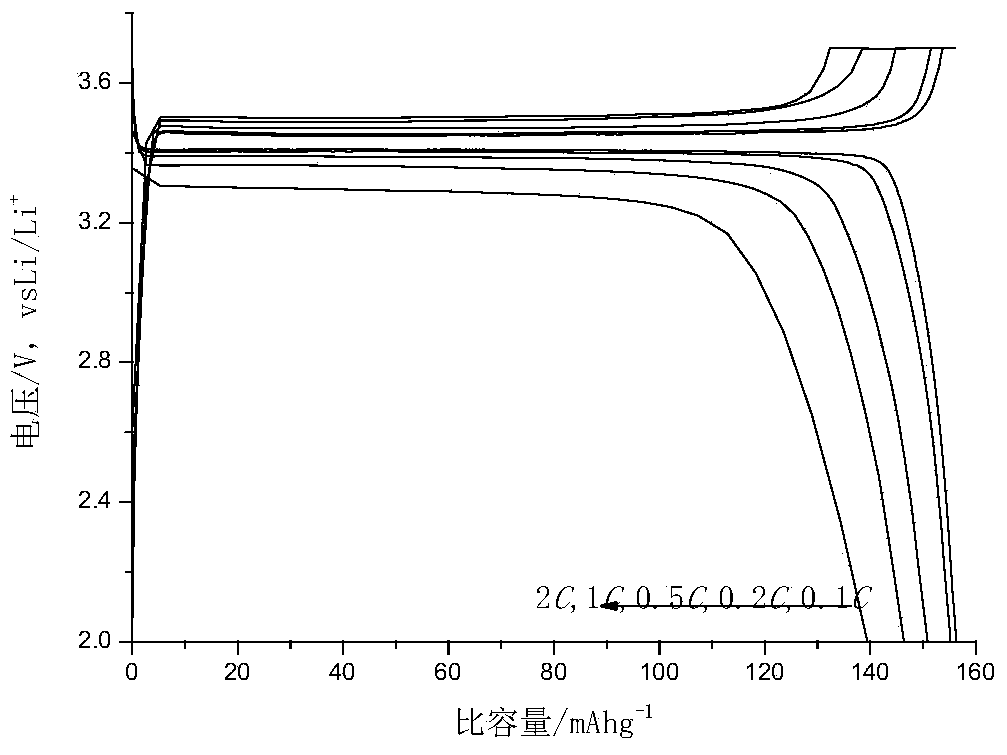

Embodiment 1

[0035] Lithium carbonate, ferrous oxalate, and ammonium dihydrogen phosphate were weighed according to the Li:Fe:P molar ratio of 1.03:0.97:1.006. Firstly, ferrous oxalate, ammonium dihydrogen phosphate and glucose accounting for 5wt% of the mixed material were added to the oblique mixer, and the homogeneous mixture was heat-treated at 570° C. for 4 hours after oblique mixing ball milling for 4 hours to obtain a composite precursor. The obtained precursor was mixed with the weighed lithium carbonate and graphite oxide accounting for 3wt% of the mixed material by ball milling in an oblique mixer for 3 hours, and then pressed to form under a pressure of 12 MPa. Put the formed body in a pressure sintering furnace protected by a 0.7MPa nitrogen-hydrogen atmosphere, calcinate at 760°C for 2 hours, cool to room temperature, and obtain micron-sized LiFePO after crushing. 4 / C composite cathode material. The carbon content in the composite cathode material detected by a carbon-sulfur...

Embodiment 2

[0037] Lithium carbonate, iron phosphate dihydrate, and lithium phosphate were weighed according to the Li:Fe:P molar ratio of 1.02:0.98:1.004. First, ferric phosphate dihydrate and starch accounting for 6wt% of the mixed material were added into the oblique mixer, and the obtained homogeneous mixture was heat-treated at 550° C. for 2 h to obtain a composite precursor after an oblique-mix ball mill. The obtained precursor was mixed with weighed lithium carbonate, lithium phosphate and superconducting carbon black accounting for 2.0 wt% of the mixed material by ball milling in an oblique mixer for 5 hours, and then pressed to form under a pressure of 14 MPa. Put the molded body in an atmosphere furnace, calcinate at 700°C for 0.5h under the protection of 0.5MPa argon, cool to room temperature, and obtain LiFePO after crushing 4 / C composite cathode material. Detecting that the carbon content in the composite positive electrode material is 3.5wt%, the particle size observed und...

Embodiment 3

[0039] Lithium hydroxide monohydrate, ferric oxide, and diammonium hydrogen phosphate were weighed according to the Li:Fe:P molar ratio of 1.05:0.95:1.01. Firstly, ferric oxide, diammonium hydrogen phosphate and polypropylene accounting for 15wt% of the mixed material were added into the oblique mixer, and after oblique mixing ball milling for 4 hours, the obtained homogeneous mixture was heat-treated at 650° C. for 5 hours to obtain a composite precursor. The obtained composite precursor was mixed with weighed lithium hydroxide monohydrate and graphite oxide accounting for 1.5wt% of the mixed material by ball milling in an oblique mixer for 6 hours, and then pressed into shape under a pressure of 9 MPa. Put the molded body in a 0.6MPa atmosphere-protected pressure sintering furnace, calcinate at 720°C for 1h under the protection of argon-hydrogen, cool to room temperature, and obtain LiFePO after crushing. 4 / C composite cathode material. It is detected that the carbon conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com