A composite of stainless steel and resin and its preparation method

A stainless steel and composite technology, which is applied in chemical instruments and methods, synthetic resin layered products, vacuum evaporation plating, etc., can solve the problems of the bonding force between stainless steel and resin not reaching the desired effect, corrosion of stainless steel products, and limited use range. , to achieve the effect of strong bonding, avoid corrosion and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

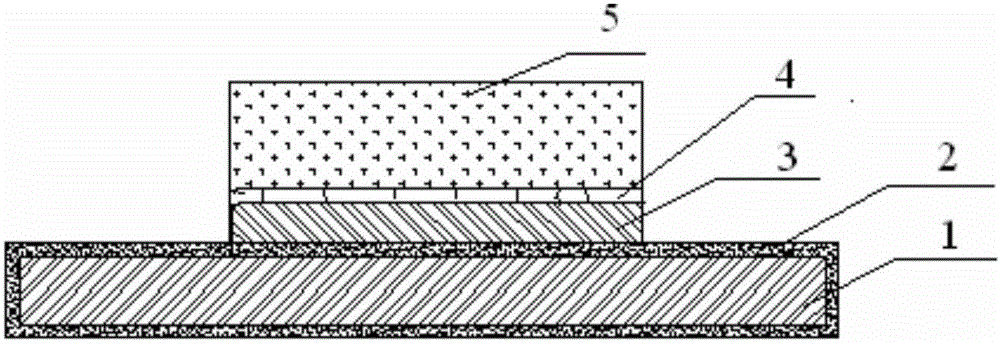

[0034] On the other hand, the present invention also provides a kind of preparation method of the composite body of stainless steel and resin, described method comprises the following steps:

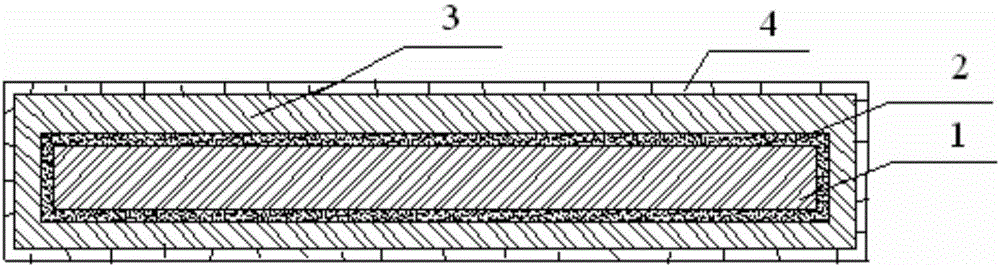

[0035] (a) Depositing an aluminum film layer 3 on at least part of the surface of the stainless steel substrate 1 by physical vapor deposition;

[0036] (b) forming an anodized film 4 on the surface of the aluminum film layer 3 by anodizing;

[0037] (c) performing electrochemical corrosion treatment on the sample obtained in step (b), so that nanopores are formed in the anodized film 4;

[0038] (d) forming a resin layer 5 by injection molding on at least part of the surface of the anodized film 4 , so that the resin layer 5 is combined with the anodized film 4 through nanopores.

[0039] According to the present invention, preferably, in step (a), a stainless steel primer layer 2 is first deposited on at least part of the surface of the stainless steel substrate 1 by physical vapor de...

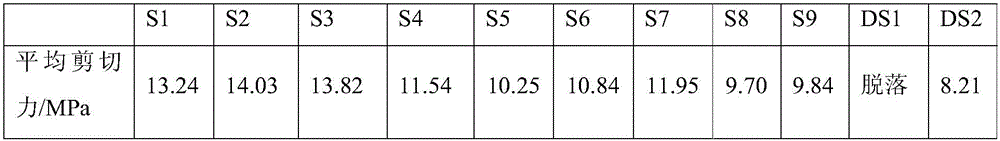

Embodiment 1

[0062] This example is used to illustrate the composite body of stainless steel and resin of the present invention and its preparation method.

[0063] (a) Substrate pretreatment: Cut 1mm thick 304 stainless steel plate into 15mm×80mm rectangular pieces, put it into a polishing machine and grind it for 20min, wash it with absolute ethanol, and then use 80 mesh quartz sand for sandblasting , rinsed with deionized water, and baked at 80° C. for 10 minutes to obtain a pretreated stainless steel substrate 1 .

[0064] (b) Magnetron sputtering coating: put the above-mentioned pretreated stainless steel substrate 1 into an intermediate frequency magnetron sputtering ion coating machine, when the pressure in the furnace is 1.0×10 -2 Argon gas was introduced at Pa, and argon ion bombardment treatment was carried out. The conditions of argon ion bombardment treatment were: keep the air pressure at 2.0Pa, bias voltage at 1000V, duty cycle at 50%, and time at 15min. After completion, st...

Embodiment 2

[0072] This example is used to illustrate the composite body of stainless steel and resin of the present invention and its preparation method.

[0073](a) Substrate pretreatment: Cut 1mm thick 304 stainless steel plate into 15mm×80mm rectangular pieces, put it into a polishing machine and grind it for 20min, wash it with absolute ethanol, and then use 80 mesh quartz sand for sandblasting , rinsed with deionized water, and baked at 80° C. for 10 minutes to obtain a pretreated stainless steel substrate 1 .

[0074] (b) Magnetron sputtering coating: put the above-mentioned pretreated stainless steel substrate 1 into an intermediate frequency magnetron sputtering ion coating machine, when the pressure in the furnace is 1.0×10 -2 Argon gas was introduced at Pa, and argon ion bombardment treatment was carried out. The conditions of argon ion bombardment treatment were: keep the air pressure at 2.0Pa, bias voltage at 1000V, duty cycle at 50%, and time at 15min. After completion, sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com