Preparation method for adjusting element ratio of Cu2ZnSnS4 film through two times of sulfuration

A copper-zinc-tin-sulfur, secondary vulcanization technology, used in electrical components, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as high tin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

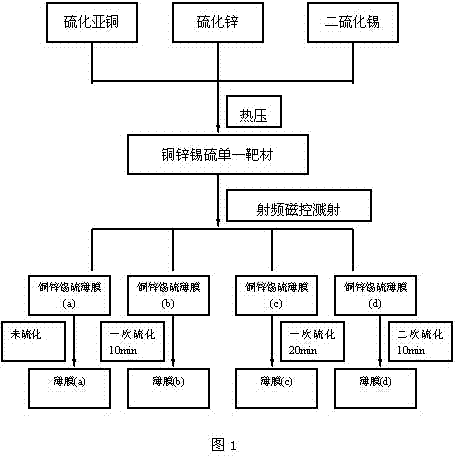

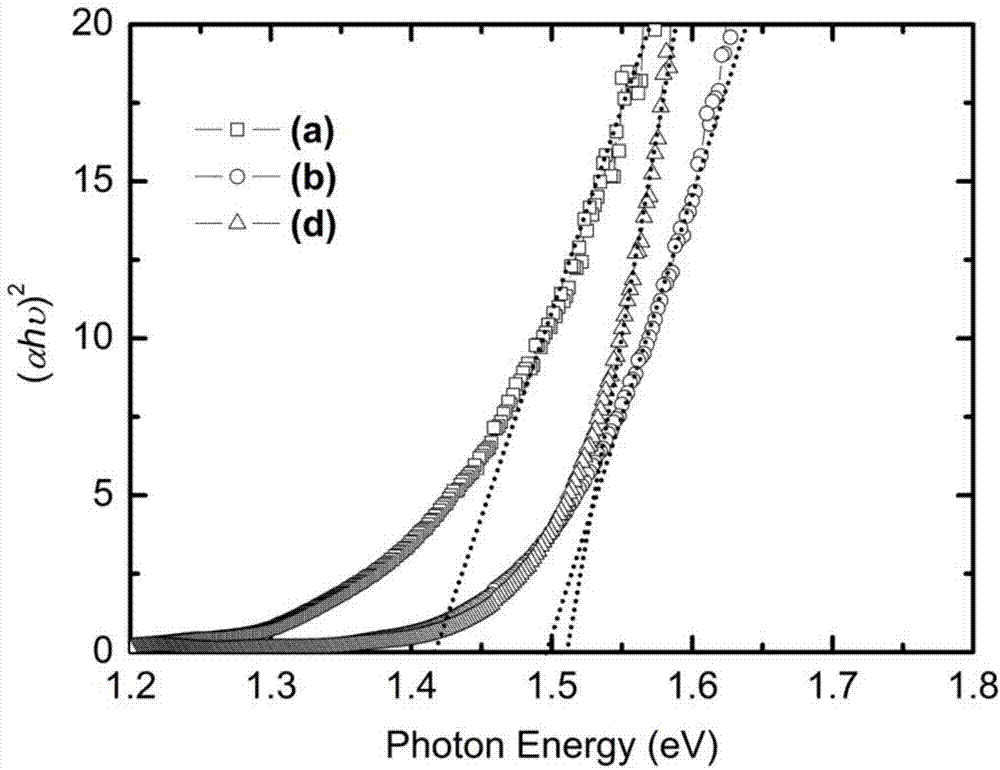

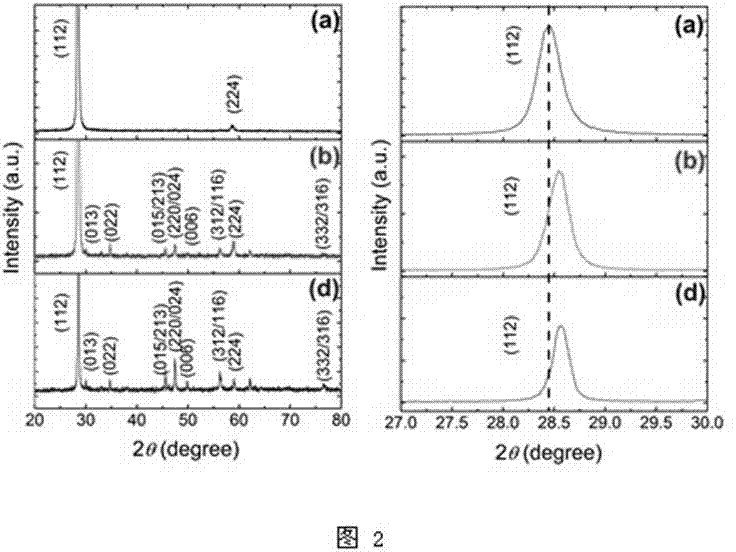

[0013] Mix the cuprous sulfide, zinc sulfide, and tin disulfide in a molar ratio of 1:1:1, and grind with an agate mortar for 4 hours. The mixed powder is subjected to high temperature hot pressing at a temperature of 700 o C. Obtain a copper-zinc-tin-sulfur single target with a chemical element ratio of 2:1:1:4, and use radio frequency magnetron sputtering to sputter a copper-zinc-tin-sulfur film on soda lime glass. The process conditions are: substrate temperature : 500 o C, Argon flow rate: 30ccm, sputtering power: 60W, sputtering pressure: 0.1Pa, vacuum degree before sputtering: 7×10 -4 Pa. Obtain 4 copper-zinc-tin-sulfur prefabricated films under the same sputtering conditions and denoted by (a), (b), (c), (d) respectively. Put the films (b), (c), (d) into a quartz tube containing 10 mg of sulfur powder, and vacuum seal the tube. Using rapid annealing furnace, first put the quartz tube with thin film (b) in the furnace, and quickly heat up to 550 o At C, keep for 10min (hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com