A method for synthesizing boron carbide powder at low temperature with high yield

A boron carbide powder, high-yield technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as low yield, and achieve lower reaction temperature, controllable morphology and structure, and reduce the yield of B4C. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

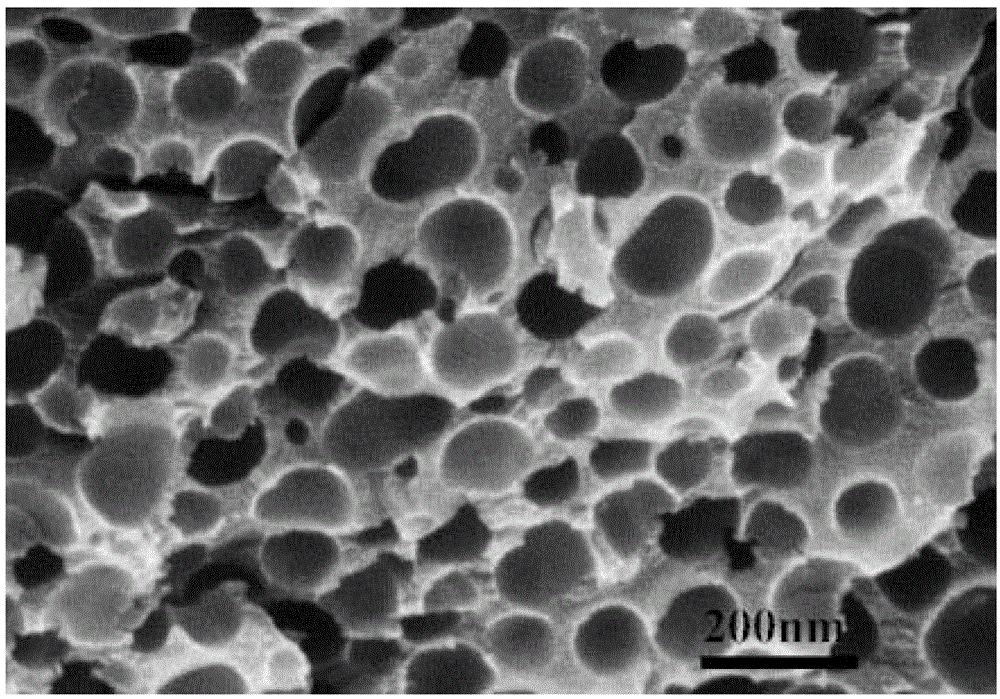

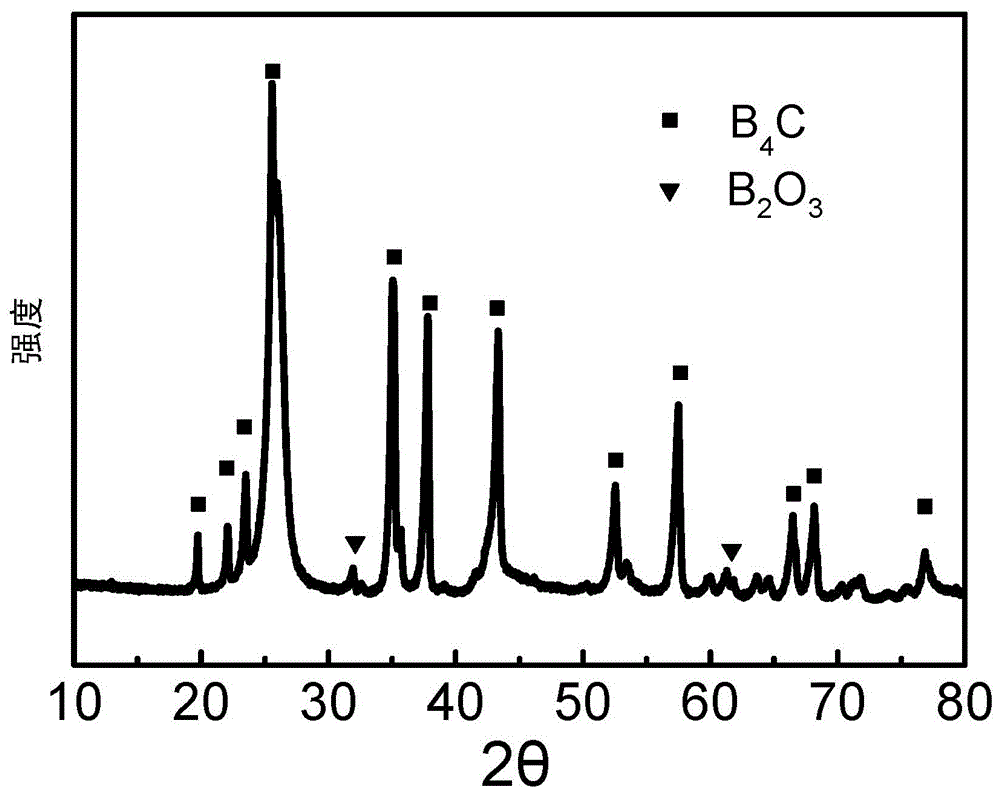

Embodiment 1

[0056] A boric acid solution with a concentration of 8.0 mol / L and a polyvinyl alcohol solution with a concentration of 2.0 mol / L were prepared respectively. Use ammonia water to adjust the pH value of the boric acid solution to 4, slowly add an appropriate amount of boric acid solution to the polyvinyl alcohol solution according to the molar ratio of boric acid / polyvinyl alcohol = 4 / 10, and stir at 85°C until the solvent is completely Evaporate to dryness to obtain a gel; place the obtained gel in a drying oven, raise the temperature to 80°C at a rate of 1°C / min, keep it warm for 12 hours, and then raise the temperature to 120°C and keep it for 16 hours to obtain a dry gel, of which 800-120°C The temperature rise rate in the temperature interval is 0.5°C / min. Put the obtained xerogel in a tube furnace for pyrolysis. The furnace is an argon atmosphere. The pyrolysis system is as follows: the heating rate is 2°C / min below 350°C, the temperature is kept at 350°C for 2 hours, and...

Embodiment 2

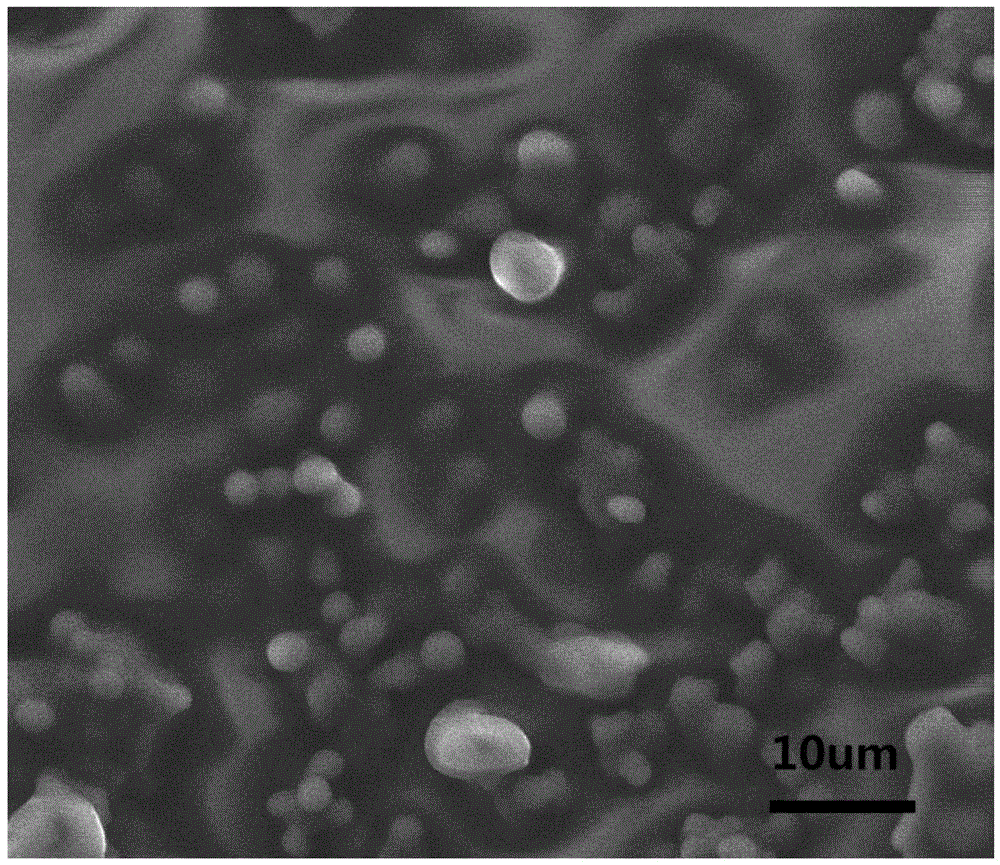

[0059] Molar ratio boric acid / polyvinyl alcohol=5 / 10, the pH value of boric acid solution is adjusted to be 5, other conditions are identical with embodiment 1, have made the B of particle diameter 1-2 μm 4 C powder, B 4 The yield of C was 13.5‰.

Embodiment 3

[0061]The molar ratio of boric acid / polyvinyl alcohol=6 / 10, the pH value of the boric acid solution is adjusted to 6, and other conditions are the same as in Example 1, and B with a particle size of 2-3 μm is obtained 4 C powder, B 4 The yield of C was 11.3‰.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com